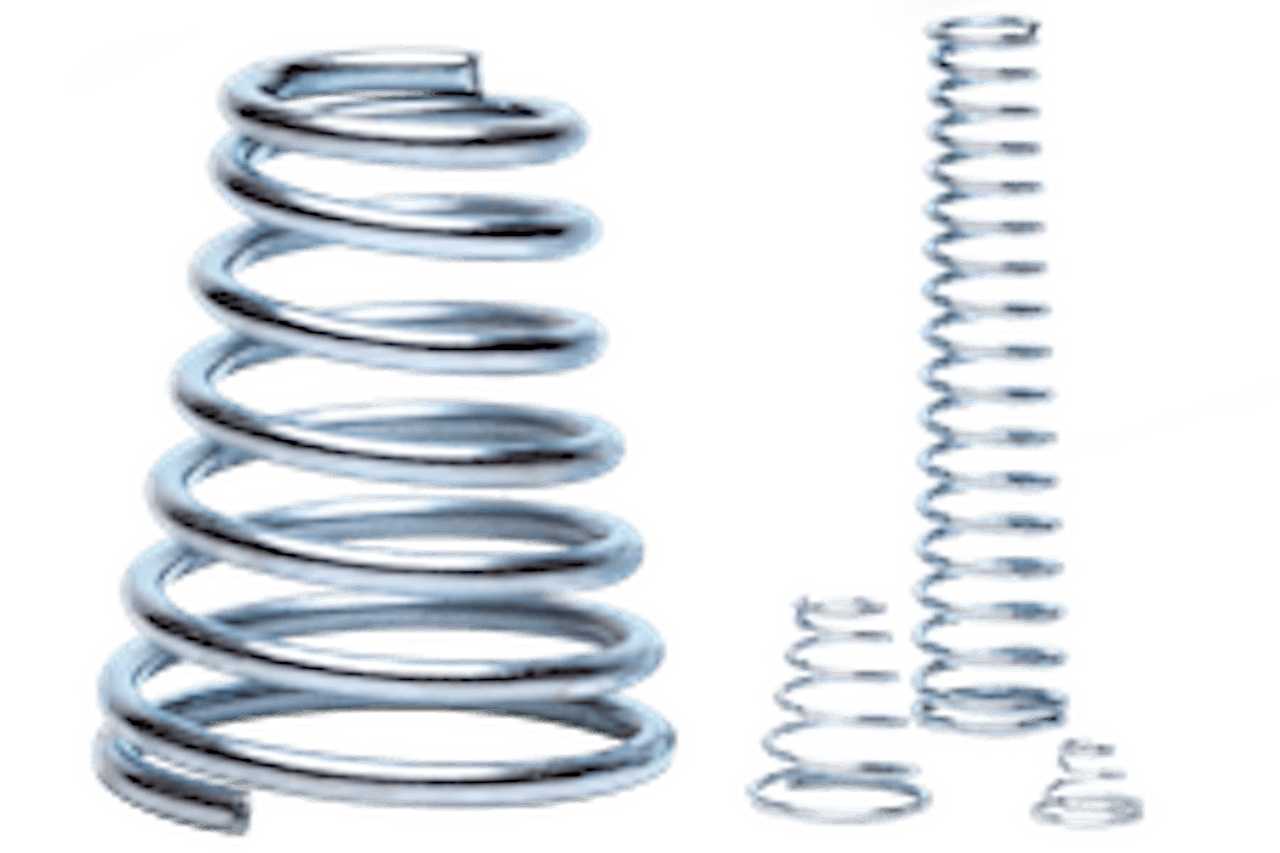

Coil Springs

Coiled Springs & Suspension Springs

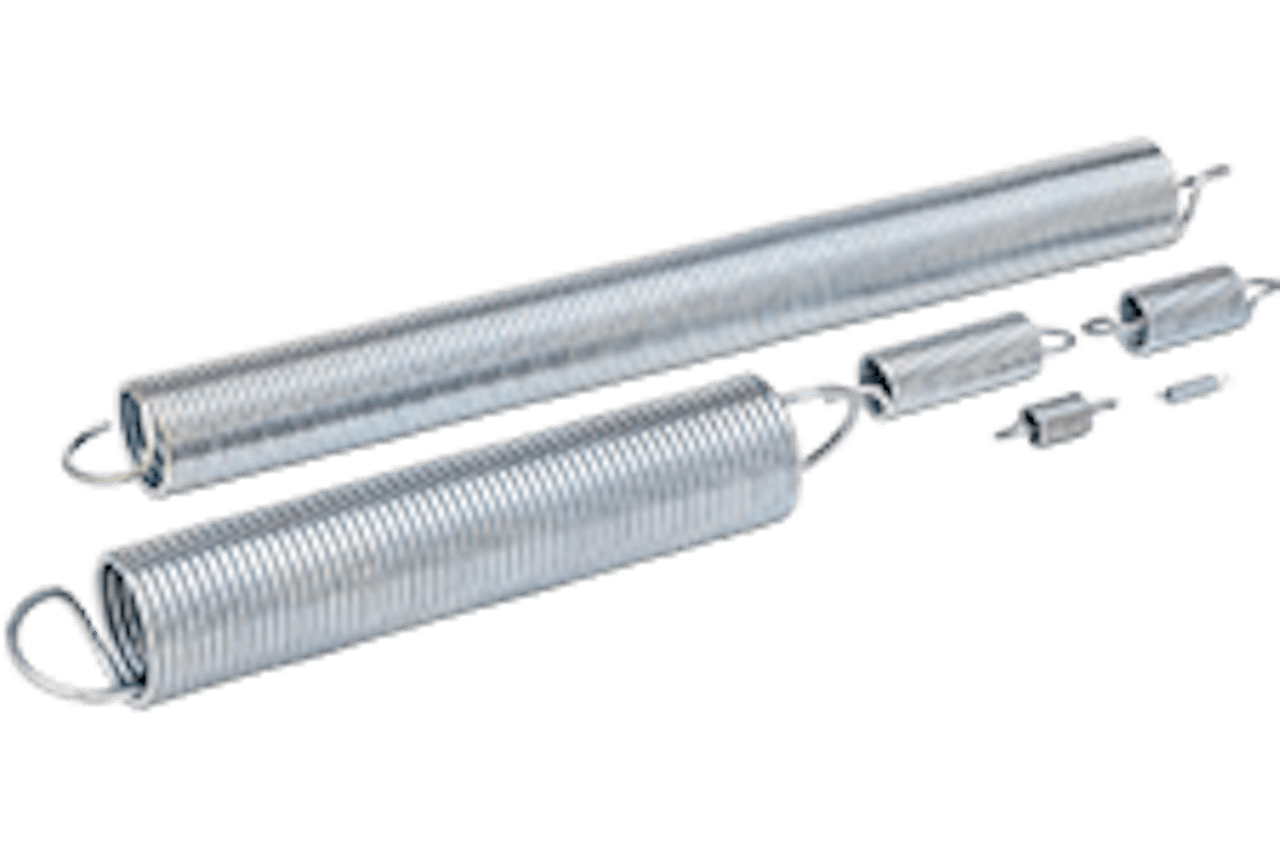

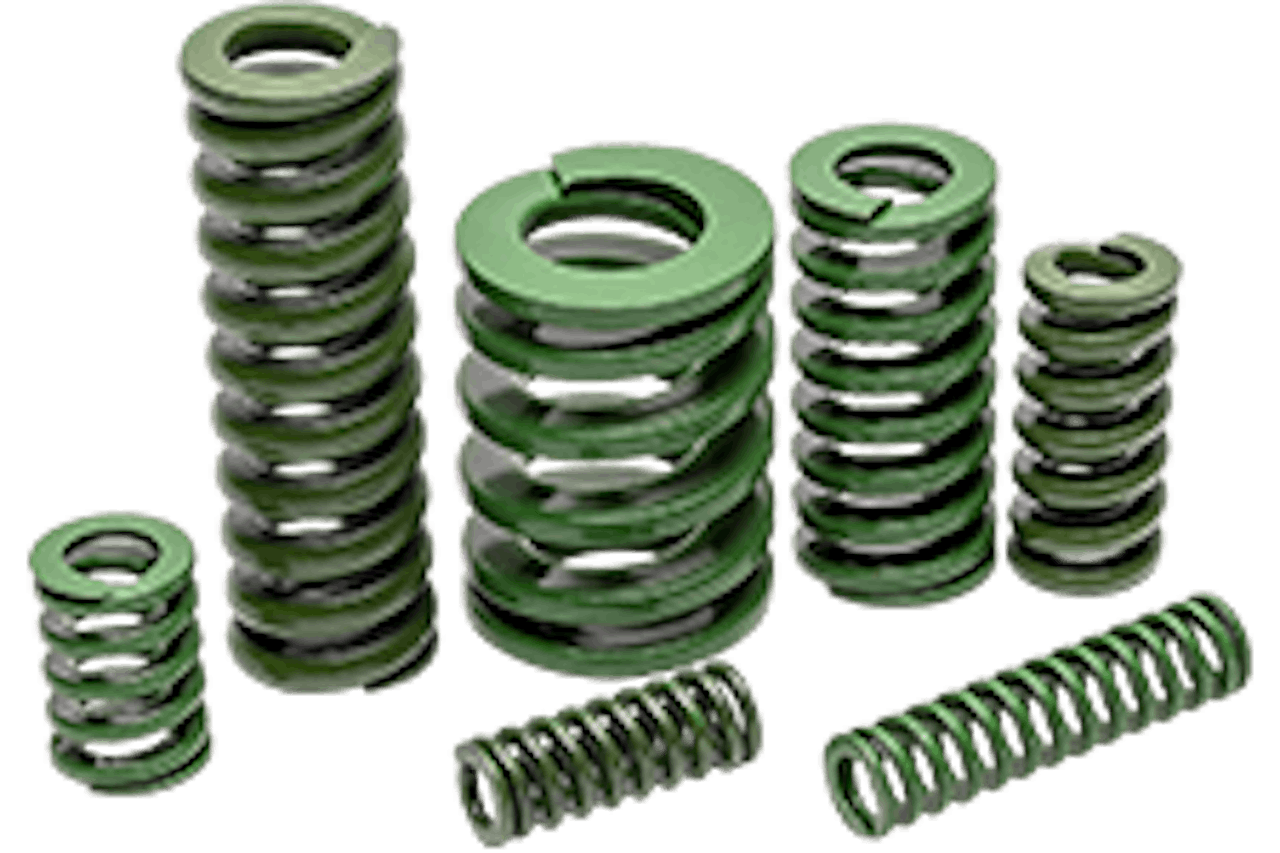

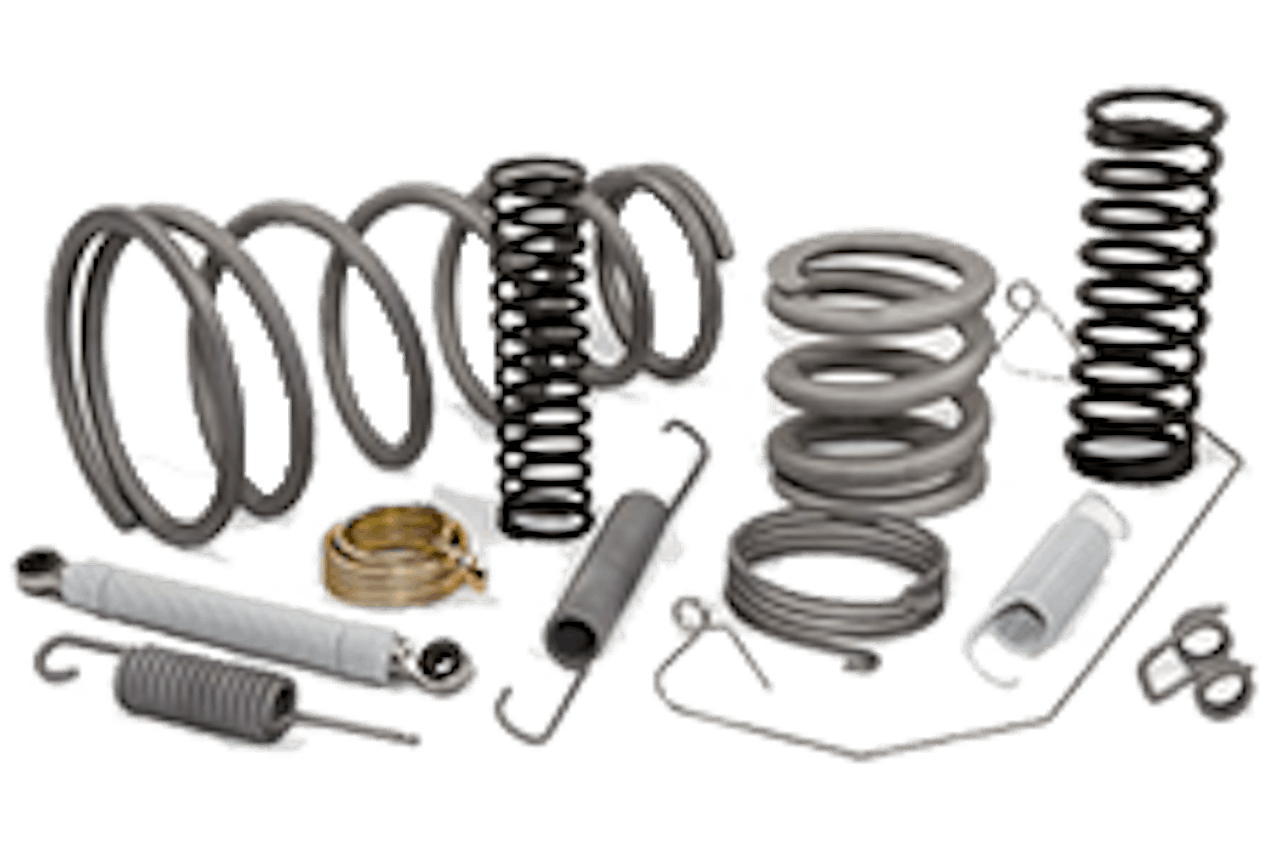

MW Components has the world's largest in-stock spring selection with over 40,000 designs and 55 million springs in inventory. We manufacture a full range of coil springs, including compression, extension, torsion, and automotive coil springs, including suspension springs. Our custom experts can also design and manufacture a spring for your specific application in any quantity, from prototype to full production.

All Coiled Spring Products

We offer stock, standard, and custom coil spring manufacturing. Used in nearly all industries, MW frequently produces industrial coil springs for a wide variety of applications. Explore all our available coil spring types below, which can be manufactured to industry-specific standards as needed for medical, aerospace, and more.

Suspension Coil Springs

Ideal for original equipment replacements, our suspension springs restore your vehicle's handling. We provide springs for over 30 car makes and models with years ranging from 1955 to 2021. Our springs are in-stock and ready-to-ship, so you can get your car back to its original performance without the wait.

-

- Original part replacement

- Sold as a pair

-

- Original part replacement

- Sold as a pair

-

- Original part replacement

- Sold as a pair

-

- Original part replacement

- Sold as a pair

-

- Original part replacement

- Sold as a pair

-

- Springs for 30+ car brands, including Acura, Dodge, Ford, Honda, Nissan, Saturn, and more

What Our Customers Are Saying

“We are very pleased with our service. My emails are responded to promptly & lead times are pretty much spot on.”

“We needed springs for our new design and the customer service rep helped put us on the right path.”

“Company is great and always keeps you informed of product delays (usually does not have any) and shipping status.”

Custom Coiled Spring Manufacturing

MW manufactures custom coil springs to your specifications. We work with all conventional spring materials as well as specialty materials, high-temperature, and titanium alloys, with wire size capabilities from from 0.004″ to 3.00″. Our multi-slide forming equipment can also produce complex hook and leg geometries for extension and torsion springs complete off the machine.

But our expertise is not limited solely to manufacturing; we also offer design and prototyping assistance and a variety of quality control and performance testing options. Our experts will gladly work with your teams to create a suitable component for your application that meets or exceeds your expectations for cycle life, hardness, resistance to environmental factors, and more.

Learn more about our custom spring services here or request a quote to get started.

Related Manufacturing Services

In addition to standard engineering and manufacturing services, we offer various additional services for your convenience. Some examples are listed here.

Finishing Services

We also offer many additional secondary finishing services to choose from to ensure your coiled spring achieves your desired look, feel, and application performance.

Materials

With over 30 manufacturing facilities operating under various product specialties and serving multiple markets from aerospace to automotive, MW is able to stock many standard and specialty materials.

Quality Standards & Certifications

Our facilities work within specialized industries that require rigorous quality and performance assurance testing, and as such as maintain several key certifications to ensure that only the best products are shipped to you.

Have Questions?

Talk with our experts today and let us help you figure out the best solution.