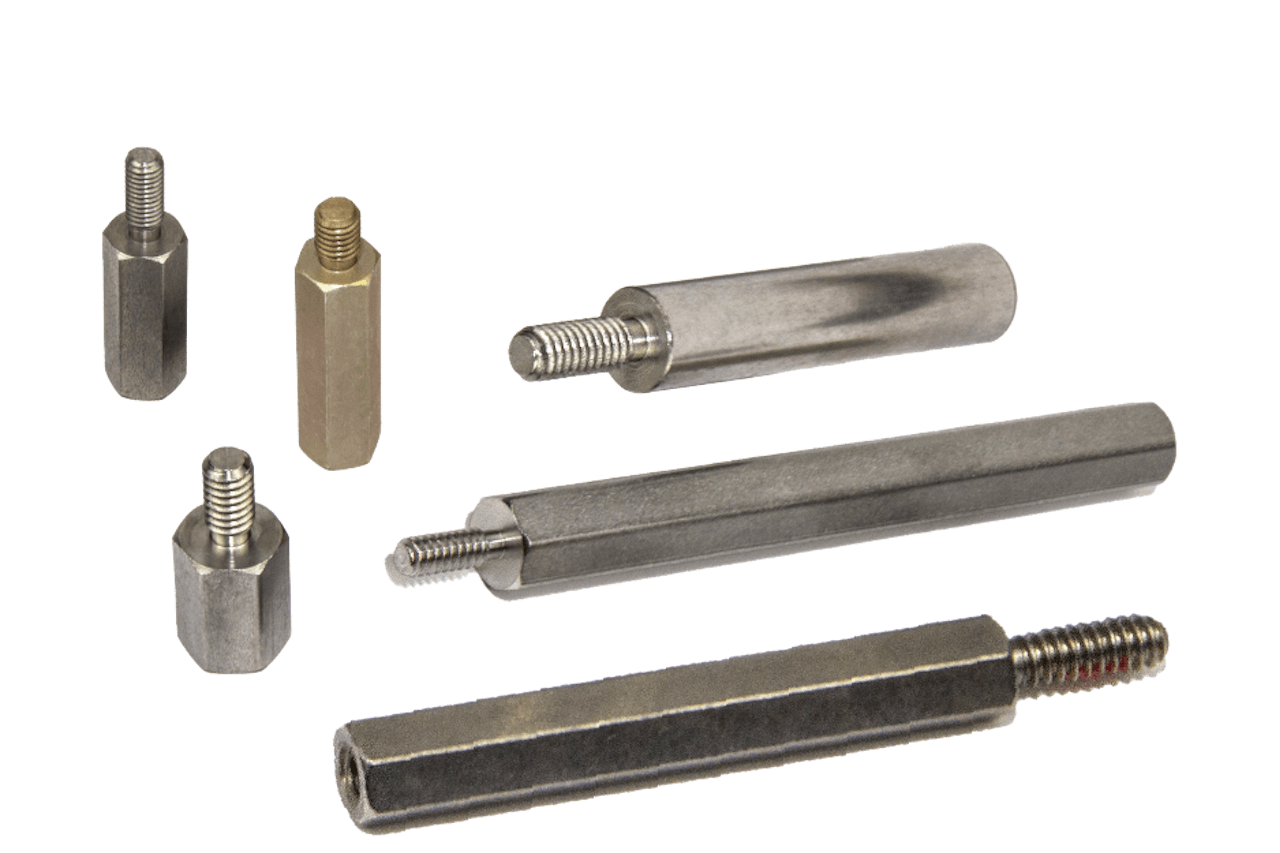

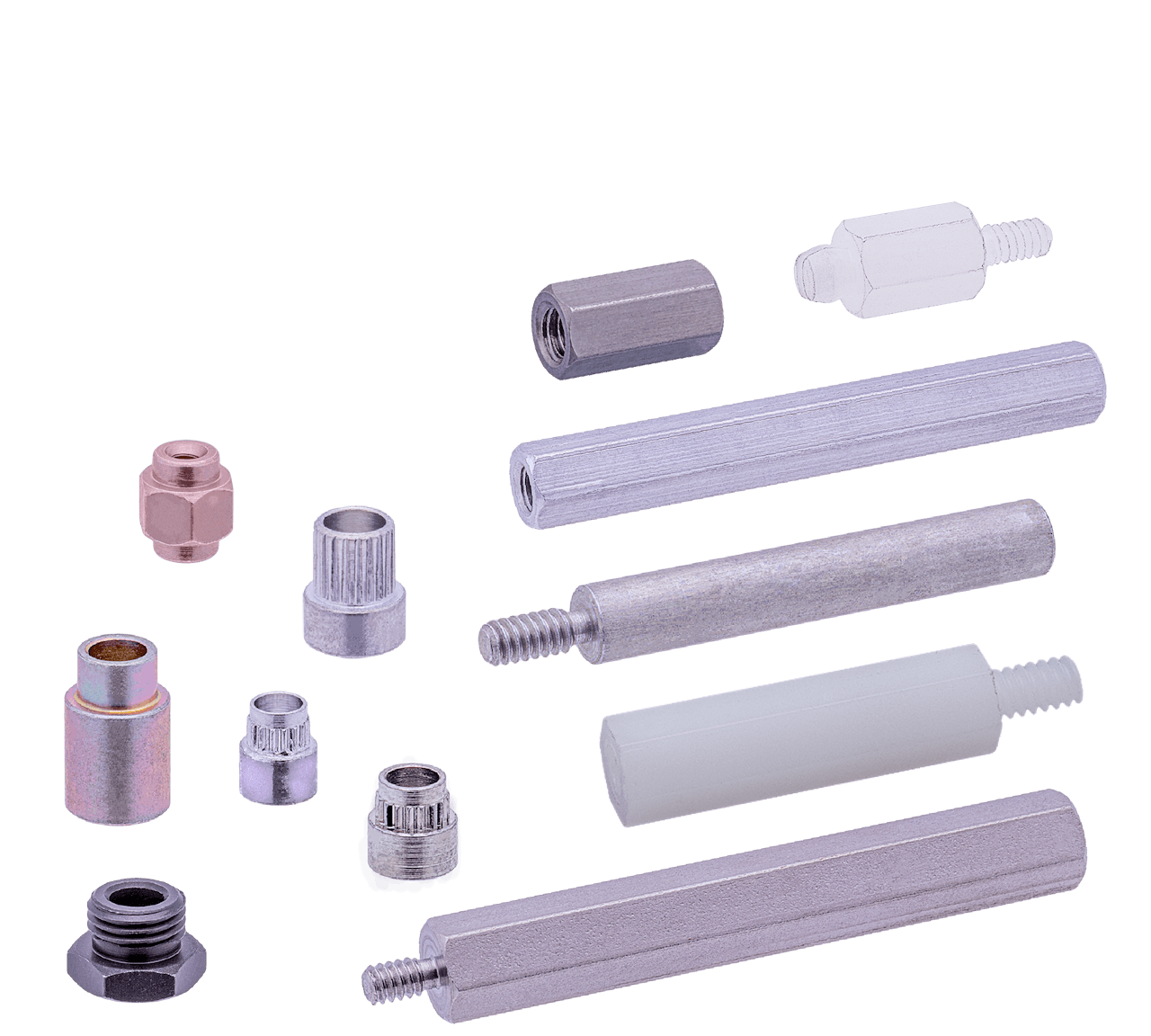

Standoffs

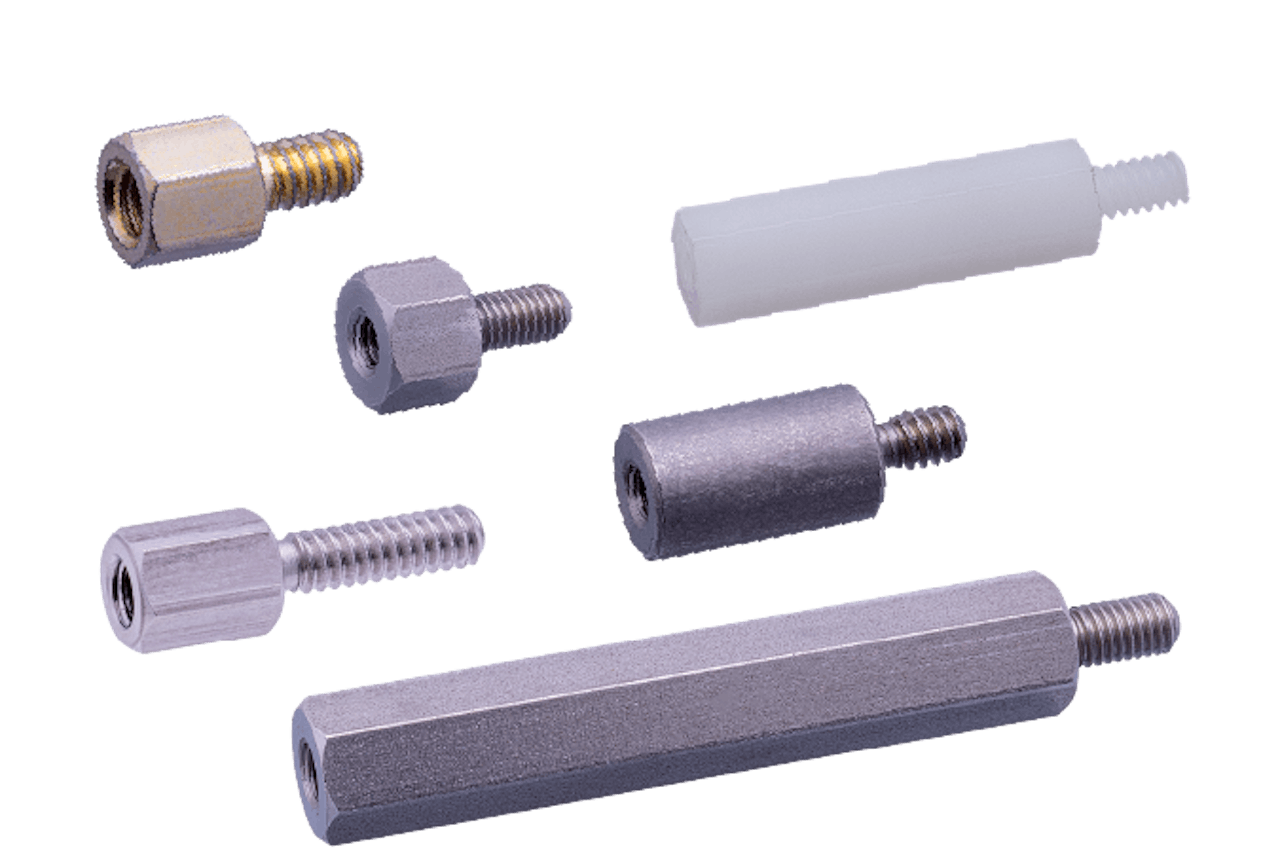

MW Components offers fast turn-around times on a wide variety of square, circular, and hex standoffs, including NAS standoffs, motherboard standoffs, MBS standoffs, and laptop and computer standoffs.

With our extensive inventory and quick turn service, we can deliver in-stock parts within one day and expedite custom solutions.

Shop Standoffs Online

Explore our extensive catalog of standoffs and filter by material, standard and metric sizes, end type, finish, and more to customize your selection. In-stock orders are typically shipped out within 24 hours.

Get Custom Standoffs Fast

We offer custom standoffs tailored to your exact specifications. Our team delivers precision-engineered solutions quickly, working with you every step of the way to bring your vision to life.

- Design & Engineering Support

- Prototyping to Full-Scale Production

- Fast Turnaround Times

- Expedited Delivery Options Through Our Quick Turn Service

Standoffs Capabilities & Services to Support Your Projects

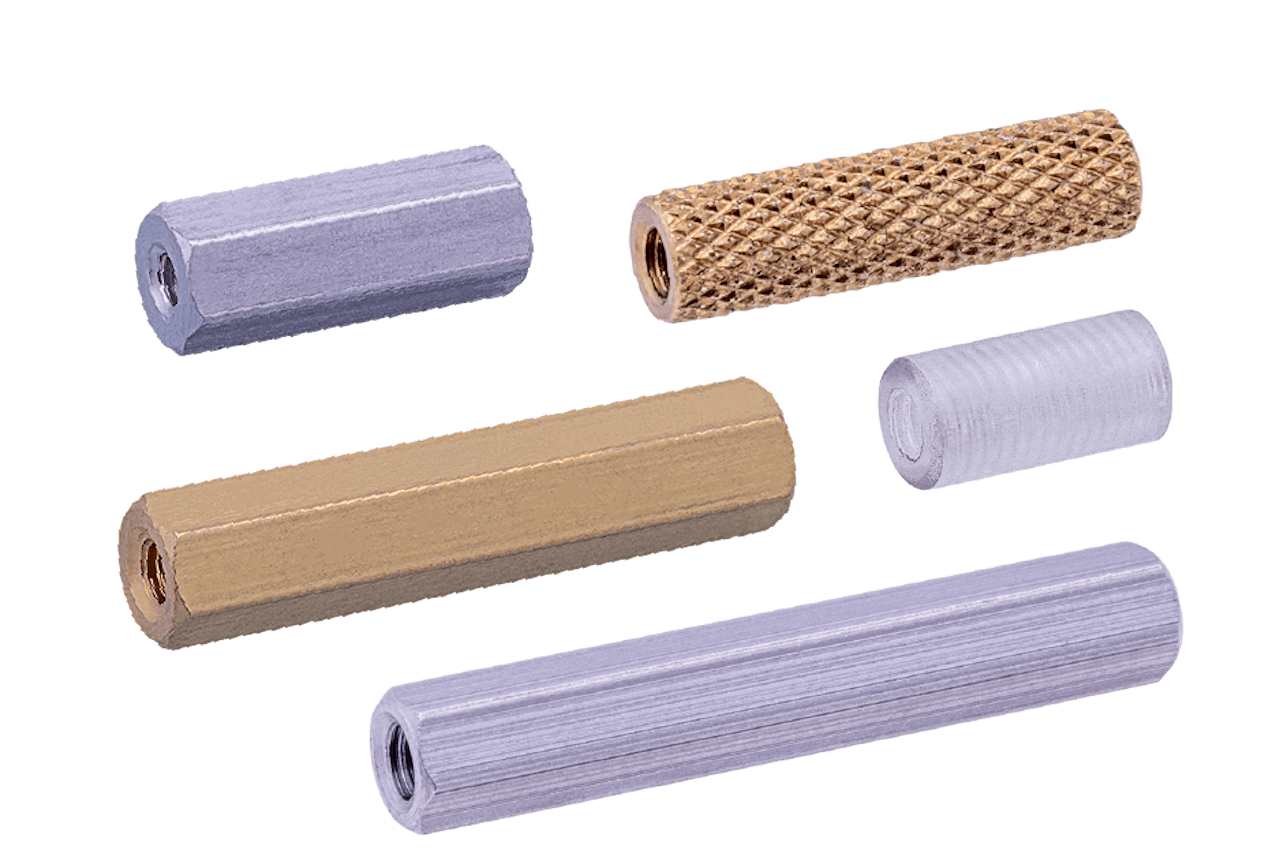

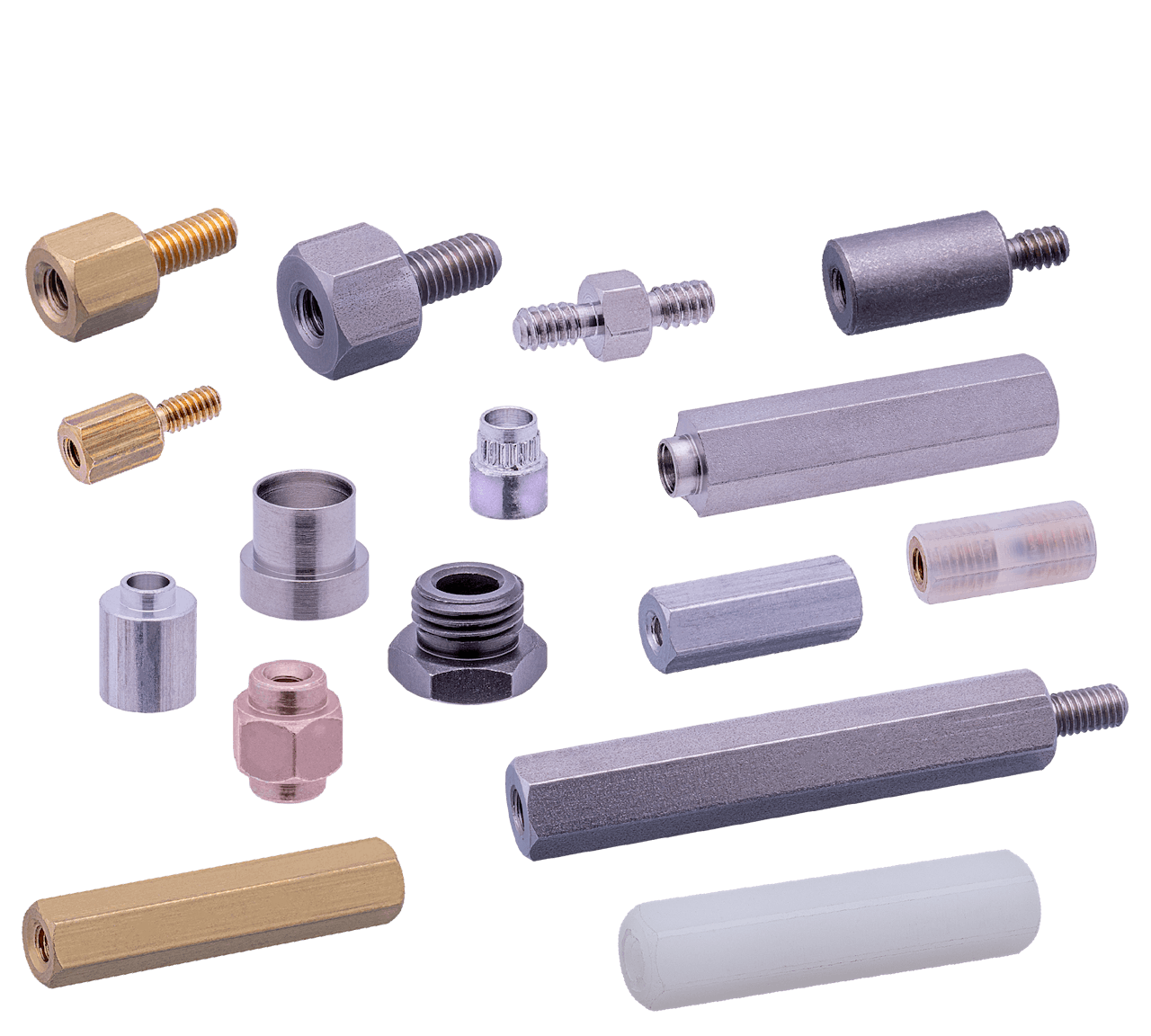

We offer a comprehensive range of standoff capabilities and services to meet your needs and specifications. Our selection of standoffs includes both metallic and non-metallic options, with tight tolerances maintained for all materials. With value-added services such as heat treatment and knurling, along with expedited solutions through our Quick Turn Service, we deliver customized standoff solutions efficiently and reliably.

Manufacturing Services

In addition to standard engineering and manufacturing services, we offer various optional services to assist you in developing the best product for your application or end-use.

- CAD Modeling

- Prototyping

- Design

- Tooling & More

CAD files for stock and standard standoffs are available for download in our Shop Online section.

Finishes and Platings

Choose from over 40 finishes, including passivation, anodized, and zinc, to ensure your standoffs meet your desired specifications. Additional processes include:

- Heat Treating

- In-House Plating

- Knurling

- Secondary Operations & More

Contact us about our in-house plating service, offering quick turnaround times. We can plate and ship stock plating parts in as little as 3 days.

Quality Materials

We offer an extensive range of standard and specialty materials, ensuring compatibility with various environments and performance requirements. If you require custom materials or manufacturing processes, contact us for custom quote information.

- Stainless Steel

- Aluminum

- Brass

- Exotic Alloys & More

Quality Certifications & Standards

At MW, we pride ourselves on creating quality products that meet or exceed industry standards. Not only do our facilities perform rigorous quality assurance testing to your specified ranges, but we also maintain several key certifications to ensure that only the best products are shipped to you.

Standoffs Resources

Swage Mount Standoffs Installation

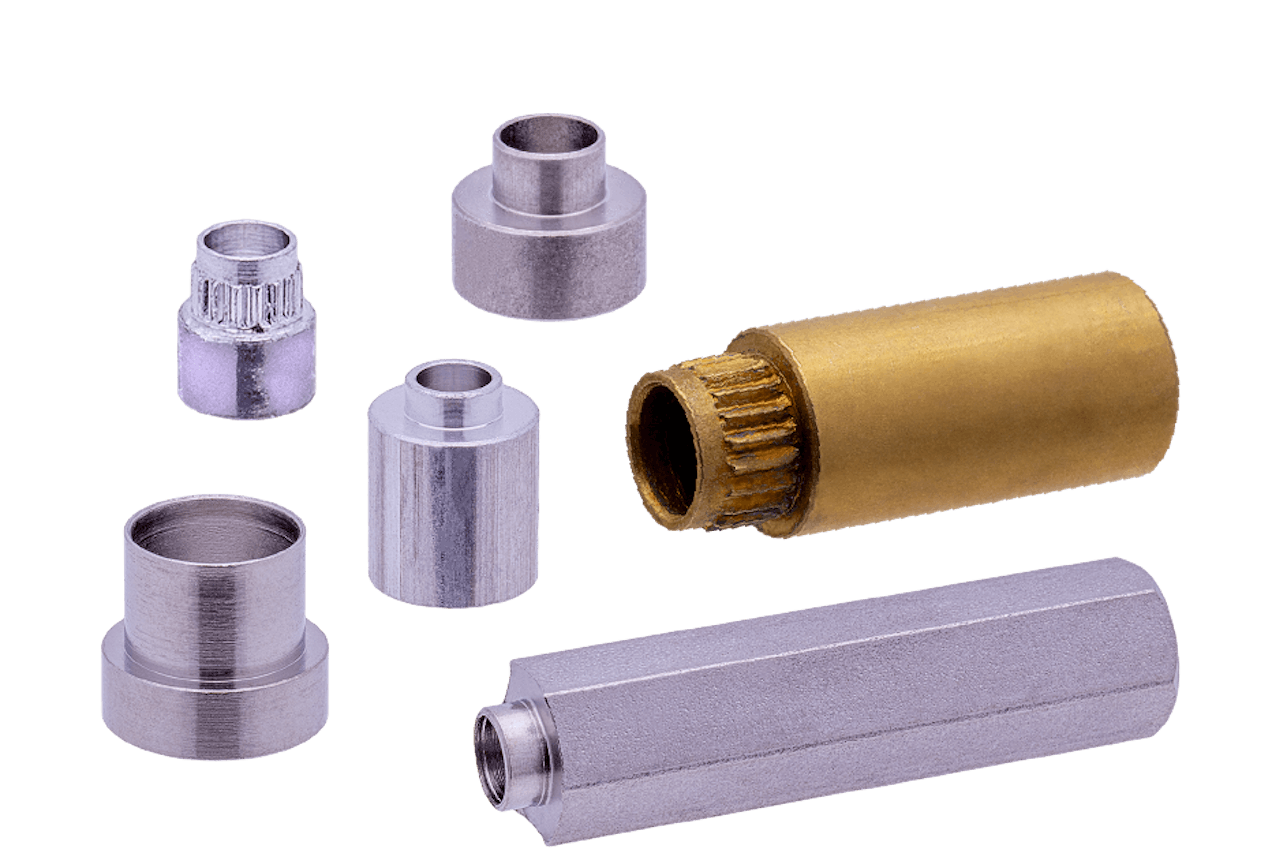

Swage mount standoffs offer a secure and efficient solution for mounting components by permanently fastening them to a surface through deformation. Swages include plain and knurled shanks, and front, back, or front and back-faced knurls.

For information on swage standoff installation, reference our Swage Standoff Installation Guide.

Types of Standoffs

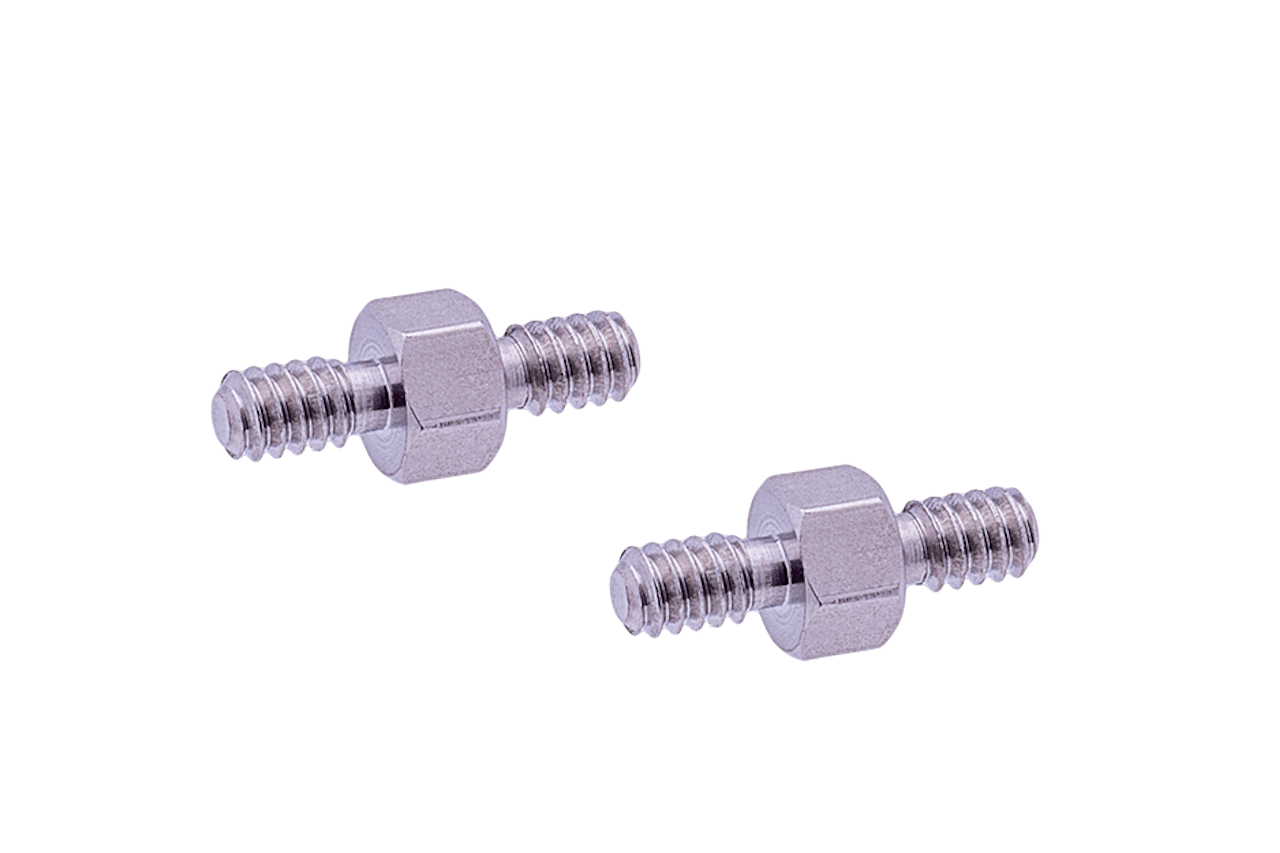

Standoffs are threaded separators that raise one assembly over another. They are critical in providing space between parts and housings and are used in PCB mounting or stacking. They are available in male-female, female-female, and male-male styles, such as swage mount, double male, double female, male-female, and self-locating. Our standoffs are available in round, hex (for wrench tightening), and square styles with regular and swaged ends in standard and Metric dimensions.