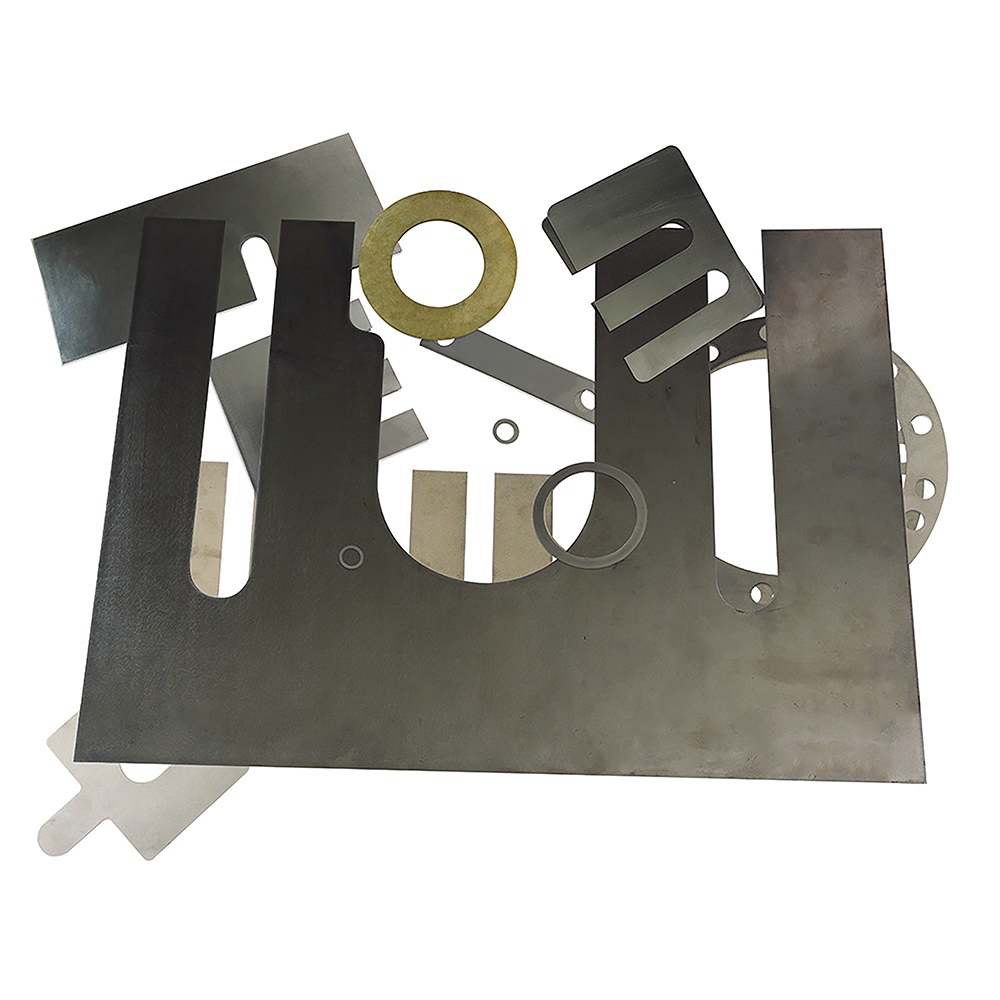

Custom Shims

A Reputation for Superior Quality - Get the Shims You Need

MW is known for custom shim manufacturing with industry-leading turnaround times. Our made-to-order shims are available with a wide variety breadth of customization options as well as standard and specialty materials. We are devoted to delivering the best possible custom shims to our customers within the timeline and requirements you need. Get a quote for custom-made shims below or shop our in-stock, ready-to-ship shim products online.

Why Choose Us for Custom Shims?

Design Support from Experts

Our experts are here to help. If you have questions about thickness, tolerance, materials, or design, don’t hesitate to reach out to our dedicated design and engineering team. We are ready and able to provide experienced advice to assist you in all your current and upcoming projects.

Shim Materials

We offer a variety of standard and specialty materials for standard and specialty shim products. The following is a small sample of our available materials, but we offer many more based on request. If you don't see what you need, contact us. We can help you get the shims you need in the material you require.

Custom Spring Specifications

Custom Shim Sizes

We specialize in custom shim manufacturing. Below is a small sample of the custom shim types and sizes we typically manufacture. Contact us for more details about customization options not listed here.

| Shim Type | Min | Max |

|---|---|---|

| Standard Shims | 2 x 2" | 8 x 8" |

| Plastic Shims | 2 x 2" | 8 x 8" |

| Thick Shims | 2 x 2" | 8 x 8" |

Typical Lead Times

We can usually provide custom shim quotes in one to two business days. Lead times will vary based on type, volume, material, and other specifications requested.

| Shim Type | Lead Time |

|---|---|

| Standard Shims | 3-5 days |

| Plastic Shims | 3-5 days |

| Thick Shims | 3-5 days |

Available Finishing Services

Custom shims can be made to exact specifications while using industry-standard finishing services.

| Finishing Service | Description |

|---|---|

| Cleaning & Polishing | Get the final product you need with enhanced appearance and protection from corrosion. |

| CNC Machining | Computer-aided software assists with milling, turning, stamping and forming. |

| Coating | Prevent corrosion and abrasion with electroplating or powder coating. |

| Kitting | Ensures speed and easy identification of coordinating parts. |