Licensed MAThread® Fasteners

MAThread fasteners are often used in the automotive and heavy truck industries and are known to improve product assembly by reducing the time required for labor, reducing scrap and rework, and minimize possible injuries obtained through repetitive motion.

Size Ranges and Configuration Options:

- Class: 8.8, 9.8, 10.9

- Grade: 5, 5.1, 8, 8.1, 8.2

- Materials: low and medium carbon steel or stainless steel

- Size Ranges: M4 - M12 / #8 - 1/2” (American standard and metric sizes available)

CUSTOM MANUFACTURING

Custom Licensed MAThread® Fasteners

Our Bensenville, IL facility specializes in custom Licensed MAThread® Fasteners and other cold-formed fasteners and assemblies. These fasteners are produced using low or medium carbon steel or stainless steel and are offered in both US standard and metric sizes as well as multiple classes and grades.

MW Components produces custom parts in multiple varieties, sizes, and configurations and works with you to develop the perfect part for your application using any combination of manufacturing and finishing services you require, including in-house Machining, Cold Forming, Cutting, Grinding, Welding, Heat Treatments, and Coatings and Surface Treatments. We even offer optional Assembly Services, Custom Packaging, and Vendor Managed Inventory as well as a selection of applicable certifications to ensure the utmost quality and performance.

Request a quote to send us your specs or configure a part.

About MAThread® and MATpoint® Fasteners

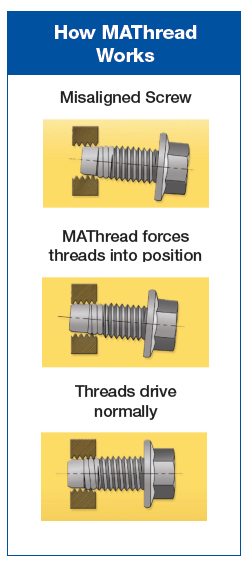

MAThread® and MATpoint® use a patented thread design that prevents virtually all threaded fasteners from cross threading and/or jamming during installation. Thanks to its thread design, misaligned MAThread fasteners automatically become aligned with their mating parts and thread normally during assembly.

By eliminating the need for initial hand threading, MAThread reduces assembly time and improves operator ergonomics.

A New Standard for Automotive Manufacturers

Due to its unique properties, MATpoint has become the preferred standard screw for companies like General Motors, Chrysler, Mercedes Benz, and Volvo Cars.

MAThread products™ versatility also allows them to be widely used in the manufacture of trucks, motorcycles, snowmobiles, all-terrain vehicles, computers, printers, furniture, construction, heavy-duty engines, and earth-moving equipment.

Improved Product Quality

With MAThread® and MATpoint®:

- Cross threading disappears

- Paint interference is eliminated

- False threading does not occur

With standard threads, each time one of these failures occur, the cost of scrap, re-work, and downtime jumps. With MAThread products, fewer plant and after-market repairs mean lower warranty costs and increased profitability.

Improved Ergonomics

Since the lead threads of MAThread products are very similar to a ball bearing in shape, operators feel almost no feedback during early fastener run-down. To operators installing thousands of fasteners per shift, this ergonomic improvement is a very significant benefit.

Improved Torque Control

MAThread products eliminate torque spikes early in the fastener run-down, which makes torque monitoring and torque/angle control much more consistent.

A Money Saver

MAThread products reduce the net cost of an assembly by dramatically improving installation time and eliminating costs resulting from waste, rework, and warranty repairs associated with conventional joints.

Available Specifications

Diameters

Standard: 1/4″-1/2″

Metric:M6-M12

Lengths

Standard: 3/8″-4″

Metric: 10mm-100mm

Grades: 10.9, 12.9, 2, 4.6, 5, 5.8, 8, 8.8, 9.8, B7, L9, Non Ferrous

Materials: 300 Series, 400 Series, Alloy Steel, Boron Alloy, Low Carbon Steel, Medium Carbon, Other Alloy, Other Stainless, Stainless Steel

Manufacturing Method: Open Die Cold Forming