Bellows Electrical Contacts

Electroformed Gold Plate Bellows Contacts

MW Components manufactures several unique lines of bellows electrical contacts. Bellows technology in electrical contacts reduces the signal loss and increases the speed in which the signal is transmitted. Rather than travel along the path of a spring, the signal travels the walls of the bellows to get the maximum signal in the least amount of time.

Our bellows electrical contacts stand apart for their exceptional performance and flexibility, which are ideal for a wide variety of applications.

CUSTOM MANUFACTURING

Custom Bellows Electrical Contacts

MW Components specializes in custom manufacturing of one-of-a-kind solutions for everything from everyday needs to mission-critical applications. Our team of bellows experts is here to provide the engineering design and manufacturing support that will make your part more efficient and effective. Request a quote to learn more about our custom manufacturing capabilities and how we can help you get the flexibility and performance you need from an electrical contact.

Types of Bellows Electrical Contacts

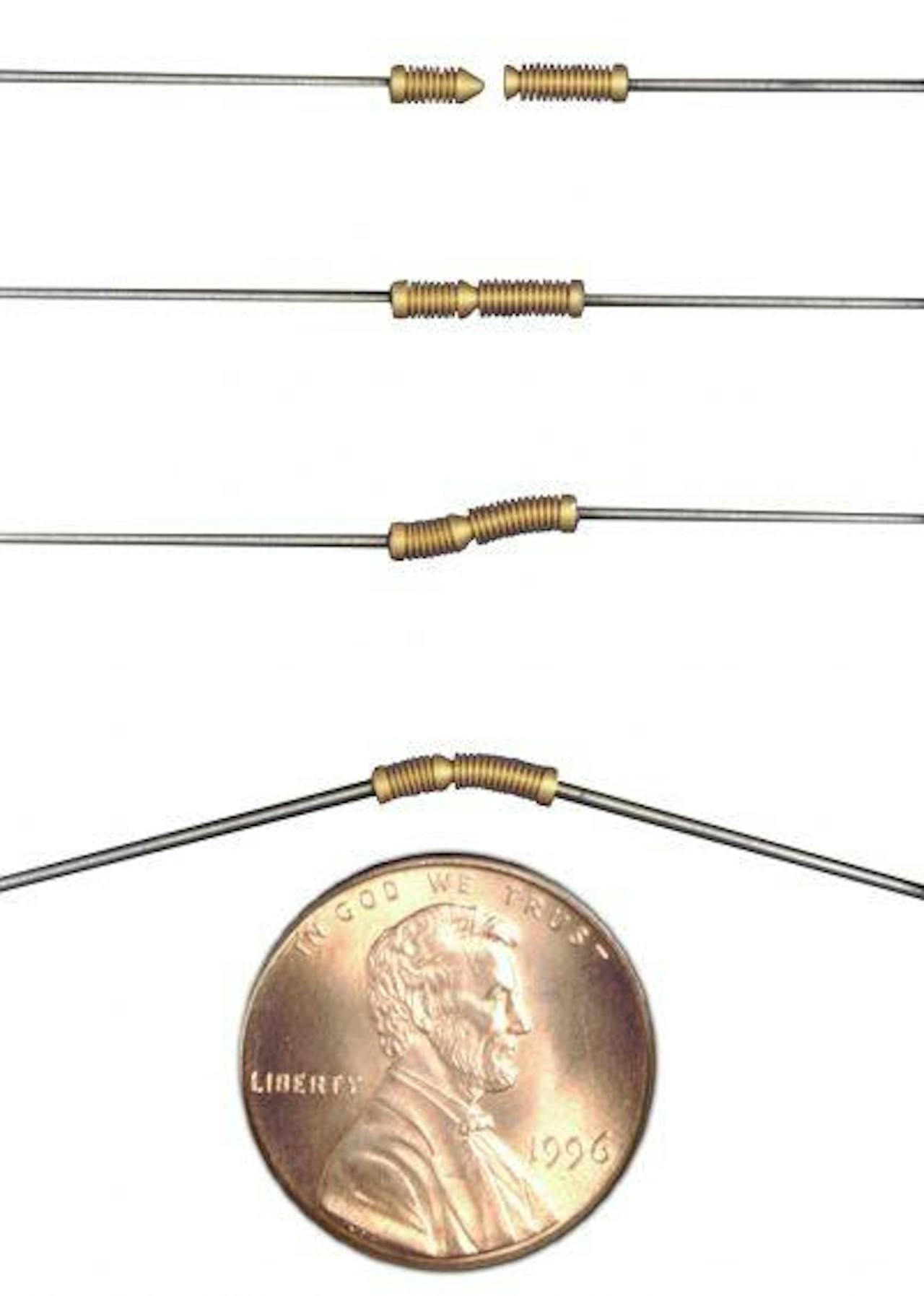

Standard Electrical Contacts

Our Servometer location manufactures standard gold-plated electrical contacts. Gold-plated, flexible bellows contacts are ideal for diodes, delay lines, wave guide components, printed circuit boards, or any application that depends on one or more spring contacts for a reliable electrical connection.

Our bellows contacts are manufactured from our proprietary FlexNickel®, a Cobalt-Nickel alloy, then gold plated to ASTM B488 to enhance their conductivity. Bellows type contacts are flexible and dynamic, with outside diameters that range from 0.037” (0.94 mm) to 0.125” (3.18 mm). They are designed to provide a lifetime of reliable interconnection in critical assemblies and can easily overcome tolerance buildup, vibration, and thermal expansion.

In many applications, it is possible to simply insert the open end of the bellows onto a pin and press assemble into place. Alternatives are to spot weld the open cup to the pin or solder the contact into place. These electrical contacts are designed to operate up to 4 amps.

Other advantages include:

- Minimum of self-inductance

- Extremely low DC resistance

- Minimum of insertion loss

- Good electrical contact between two mating parts with moderate forces

- Lifetime spring reliability (100 cycles to infinity)

- Miniature size capability

- Seamless and non-porous with no permeability to dust, dirt, or moisture

- Reduce tolerance build-up

- Maximum current rating of 4 amps

- Operating temperature -423 °F to 260 °F with no loss of spring rate

- Superior conductivity at higher frequencies (gigahertz (GHz) range and higher)

| Part Number | Outside Diameter (in) | Overall Length (in) | Convolution Length (in) | Max Compression Stroke (in) | Min Force at Full Compression (oz) | Metallic OHMS D.C. Resistance | Surface Finish |

|---|---|---|---|---|---|---|---|

| 1571-1 | 0.105 | 0.055 | 0.044 | 0.015 | 3 | 0.005 | .00005" gold |

| 1571-2 | 0.085 | 0.055 | 0.044 | 0.015 | 4 | 0.005 | .00005" gold |

| 2012 | 0.125 | 0.197 | 0.135 | 0.065 | 4 | 0.009 | .00005" gold |

| 2013 | 0.125 | 0.16 | 0.122 | 0.06 | 4 | 0.008 | .00005" gold |

| 2014 | 0.125 | 0.178 | 0.146 | 0.072 | 3.5 | 0.01 | .00005" gold |

| 2023 | 0.245 | 0.081 | 0.076 | 0.035 | 6 | 0.004 | .00005" gold |

| 2146 | 0.066 | 0.082 | 0.057 | 0.03 | 1.1 | 0.013 | .00005" gold |

| 2156 | 0.096 | 0.114 | 0.082 | 0.047 | 2.4 | 0.011 | .00005" gold |

| 2159 | 0.055 | 0.075 | 0.049 | 0.022 | 1.37 | 0.048 | .00005" gold |

| 2173 | 0.125 | 0.104 | 0.093 | 0.041 | 2.3 | 0.019 | .00005" gold |

| 2185 | 0.064 | 0.063 | 0.028 | 0.012 | 1.79 | 0.026 | .00005" gold |

| 2223 | 0.089 | 0.111 | 0.064 | 0.028 | 4.91 | 0.027 | .00005" gold |

| 2392 | 0.155 | 0.188 | 0.064 | 0.025 | 3.5 | 0.007 | .00005" gold |

| 2510 | 0.037 | 0.08 | 0.043 | 0.012 | 0.22 | 0.03 | .00005" gold |

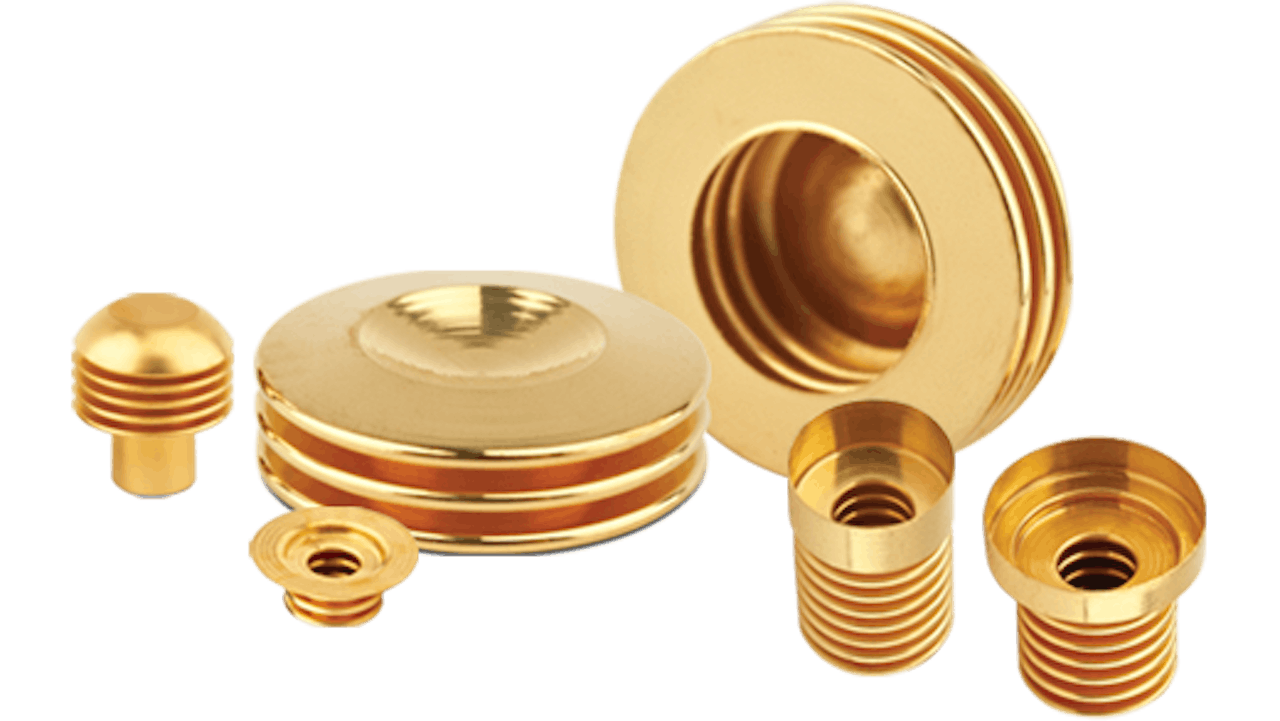

Interconnectric Gold Contacts

Interconnect gold plated bellows electrical contacts are available in both male and female configurations for applications that require two parts to be paired together. The conical-shaped tip of the male gold contact creates self-alignment with the concave conical shape of the female receptacle. This flexible construction allows them to compensate for angular and parallel misalignments as they connect. They can also be used individually if the application requires it. Other applications will have the contact make an electrical connection with a pin or feedthrough hole. The self-aligning contacts will minimize shock and vibration in dynamic applications and help overcome tolerance build-up or stacking when pairing two circuit boards together. This can reduce overall scrap cost of assembly components. They are a low-cost solution to expensive alternative assemblies and components.

Outside diameters range from 0.037″ to 0.125″. The contact springs are manufactured from electrodeposited nickel and gold-plated to ASTM B488 to enhance their conductivity and provide extremely low DC resistance with a minimum of insertion loss. They are designed to provide lifetime spring and force repeatability

In many applications, it is possible to simply insert the open end of the bellows onto a pin and press assemble into place. Alternatives are to spot weld the open cup to the pin or solder the contact into place. Servometer electrical contacts are designed to operate up to 4 amps.

Other advantages include:

- Minimum of self-inductance

- Extremely low DC resistance

- Minimum of insertion loss

- Good electrical contact between two mating parts with moderate forces

- Lifetime spring reliability (100 cycles to infinity)

- Miniature size capability

- Seamless and non-porous with no permeability to dust, dirt, or moisture

- Reduce tolerance build-up

- Maximum current rating of 4 amps

- Operating temperature -423 °F to 260 °F with no loss of spring rate

- Superior conductivity at higher frequencies (gigahertz (GHz) range and higher)

| Part Number | Outside Diameter (in) | Overall Length (in) | Convolution Length (in) | Type | Max Compression Stroke (in) | Max Angular Misalignment (degrees) | Max Parallel Misalignment (in) | Min Force at Full Compression (oz) | Metallic OHMS D.C. Resistance |

|---|---|---|---|---|---|---|---|---|---|

| SK-18636 | 0.125 | 0.271 | 0.144 | lllll> | 0.037 | 21 | 0.01 | 1.616 | 0.020 |

| SK-18637 | 0.125 | 0.322 | 0.236 | >lllll | 0.053 | 30 | 0.025 | 2.315 | 0.015 |

| SK-18642 | 0.066 | 0.17 | 0.092 | lllll> | 0.02 | 22 | 0.007 | 0.755 | 0.019 |

| SK-18643 | 0.066 | 0.212 | 0.156 | >lllll | 0.03 | 32 | 0.017 | 1.132 | 0.028 |

| SK-18646 | 0.096 | 0.231 | 0.115 | lllll> | 0.029 | 21 | 0.008 | 1.786 | 0.015 |

| SK-18647 | 0.096 | 0.264 | 0.195 | >lllll | 0.042 | 31 | 0.021 | 2.587 | 0.022 |

| SK-18648 | 0.037 | 0.111 | 0.053 | lllll> | 0.013 | 25 | 0.005 | 0.187 | 0.028 |

| SK-18649 | 0.037 | 0.136 | 0.091 | >lllll | 0.019 | 36 | 0.011 | 0.275 | 0.040 |

Operating Conditions for Standard and Interconnect Contacts

Life expectancy for these products can range from 100 cycles to infinite. For greater life cycles, the maximum compression is reduced by 20% for 100,000 cycles and by 30% for infinite life. Our contacts can be used safely up to 260 degrees F while maintaining their full spring qualities and have no low-temperature limit.

These products are rated for a maximum of 4 amps.

Maximum compressions indicated in the charts above are for 1,000 cycle life. The maximum amount of compression is reduced by 20% for 100,000 cycles and by 30% for 100 million.