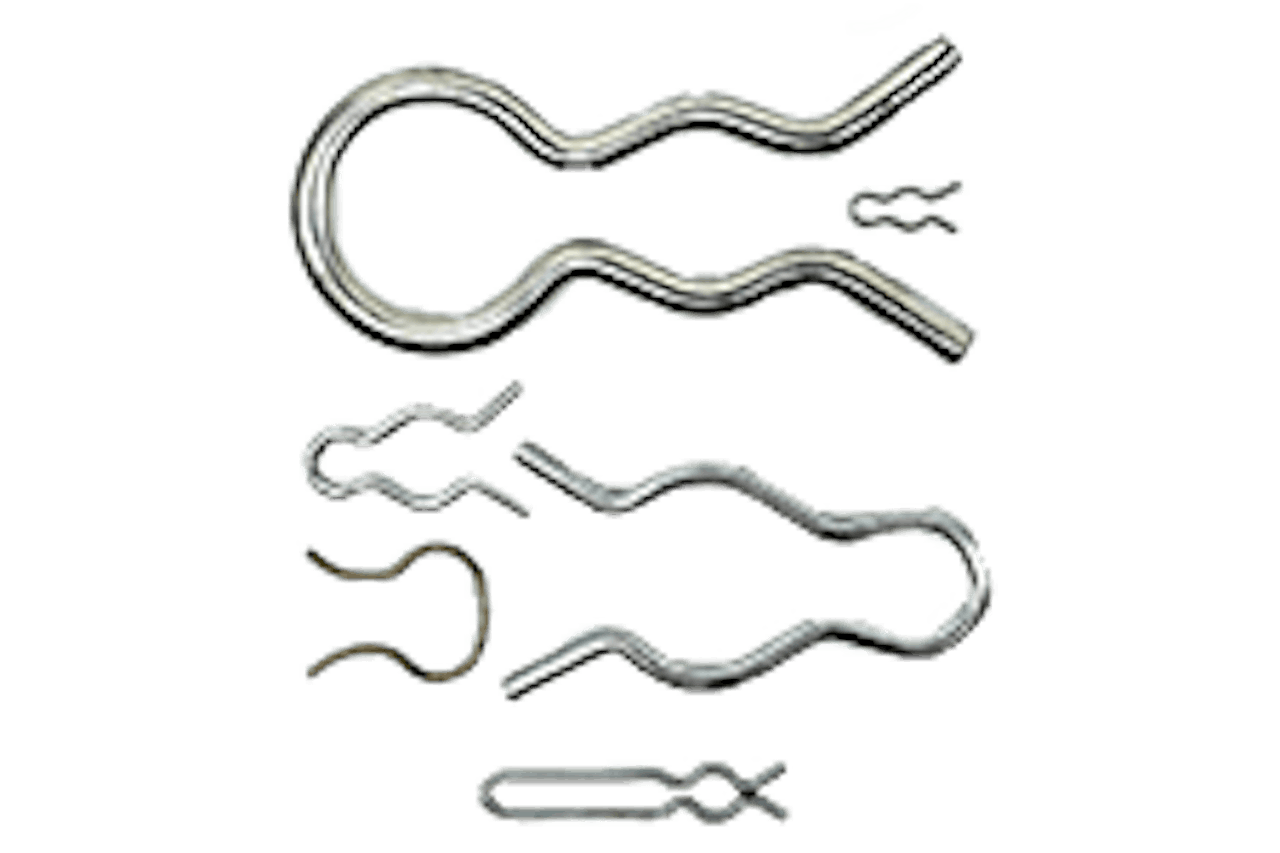

Cotter Pins

Cotter pins, or split pins, are used to lock fasteners in a secure position. Several MW facilities, including Western Wire, produce stock and custom cotter pins for commercial use, railcar, military, aerospace, defense, and more.

We offer commercial-grade cotter pins configured to ASME B18.8.1 specifications, wedge-fast cotter pins, military cotter pins including MS24665 and MS9245, and NAS parts. We also produce multiple styles and configurations in imperial and metric sizes including, extended prongs, hammerlocks, chisel points, tapered points, humped, tee heads, and self-locking cotter pins. Download the Cotter Pin Brochure for details.

Buy In-Stock Cotter Pins

Purchase our most popular extended prong, chisel point cotter pins online. These cotter pins are in-stock and available for immediate shipping. Additional sizes, materials and designs can be manufactured to fit your needs.

COTTER PIN SUPPLIER

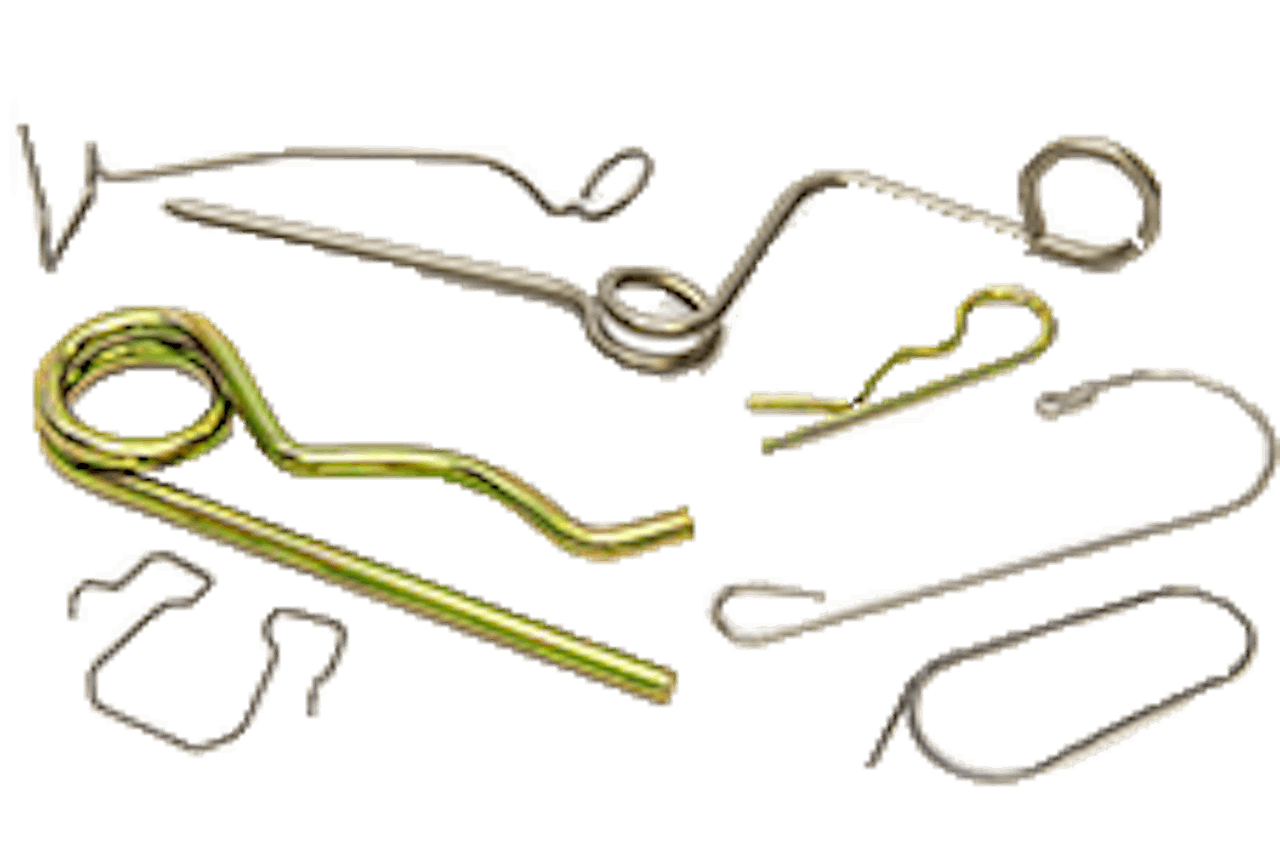

Custom Cotter Pins

Our precision machining produces custom cotter pins, hitch pins, other pins, wire fasteners, and custom wire forms made to your blueprints. We work with various materials, finishes, coatings, styles, and sizes to produce the precise component your project requires.

Custom capabilities for our custom pins include prototyping and various coatings or surface treatments including, plating, passivation, cleaning, polishing, and heat treatments. For your convenience, we also offer custom packaging and JIT (Just In Time) delivery as requested. We are ISO 9001 certified and offer both military and commercial-grade parts. Certifications verifying traceability and compliance are available as needed.

Cotter Pin Manufacturer

Cotter pins, hitch pins, wire fasteners, and other pins and wire-formed products are produced at our Western Wire facility in Fenton, MO. Western Wire specializes in custom products, tight tolerances, and fast turnaround. We produce a wide range of wire forms and pins to precise customer specifications.

Our production capabilities are extensive and include sizing capabilities from 0.01" to 0.625", a vast raw material inventory, various coating and surface treatment options, Just In Time Delivery, ISO9001 certification, and more. Whether you need a single prototype, to millions of parts, we offer precision and quality for every part we produce.

Common Cotter Pin Types

Cotter pins are available in a wide variety of styles and can custom manufactured to match your design. Below are some of the most common and popular cotter pin types available. MW manufactures these and many other types of cotter pins in a variety of plated finishes.

-

Extended Prong, Chisel Point Cotter Pin

Extended Prong, Chisel Point Cotter Pin -

Hammerlock Cotter Pin

Hammerlock Cotter Pin -

Even End, Chisel Point Cotter Pin

Even End, Chisel Point Cotter Pin -

Humped Cotter Pin

Humped Cotter Pin -

Extended Prong, Taper Point Cotter Pin

Extended Prong, Taper Point Cotter Pin -

Self-Locking Cotter Pin

Self-Locking Cotter Pin -

Tee Head Cotter Pin

Tee Head Cotter Pin -

Even End, Taper Point Cotter Pin

Even End, Taper Point Cotter Pin

Related Manufacturing Services

In addition to standard manufacturing services, we offer various optional services to assist you in developing the best product for your application or end-use.

Finishing Services

MW specializes in custom component manufacturing and offers a variety of optional finishing services to complete your custom component. Our finishes and surface treatments for custom pins include plating, passivation, cleaning and polishing, and heat treatments. Below is a list of the finishing services and treatments most often requested for custom pins.

Quality Materials

Our cotter pins are produced from a variety of standard and specialty materials. Some common materials we work with are listed below; however, our manufacturing capabilities are vast and we can work with practically any hard-drawn material. For information on custom materials and manufacturing processes, contact us for a custom quote.