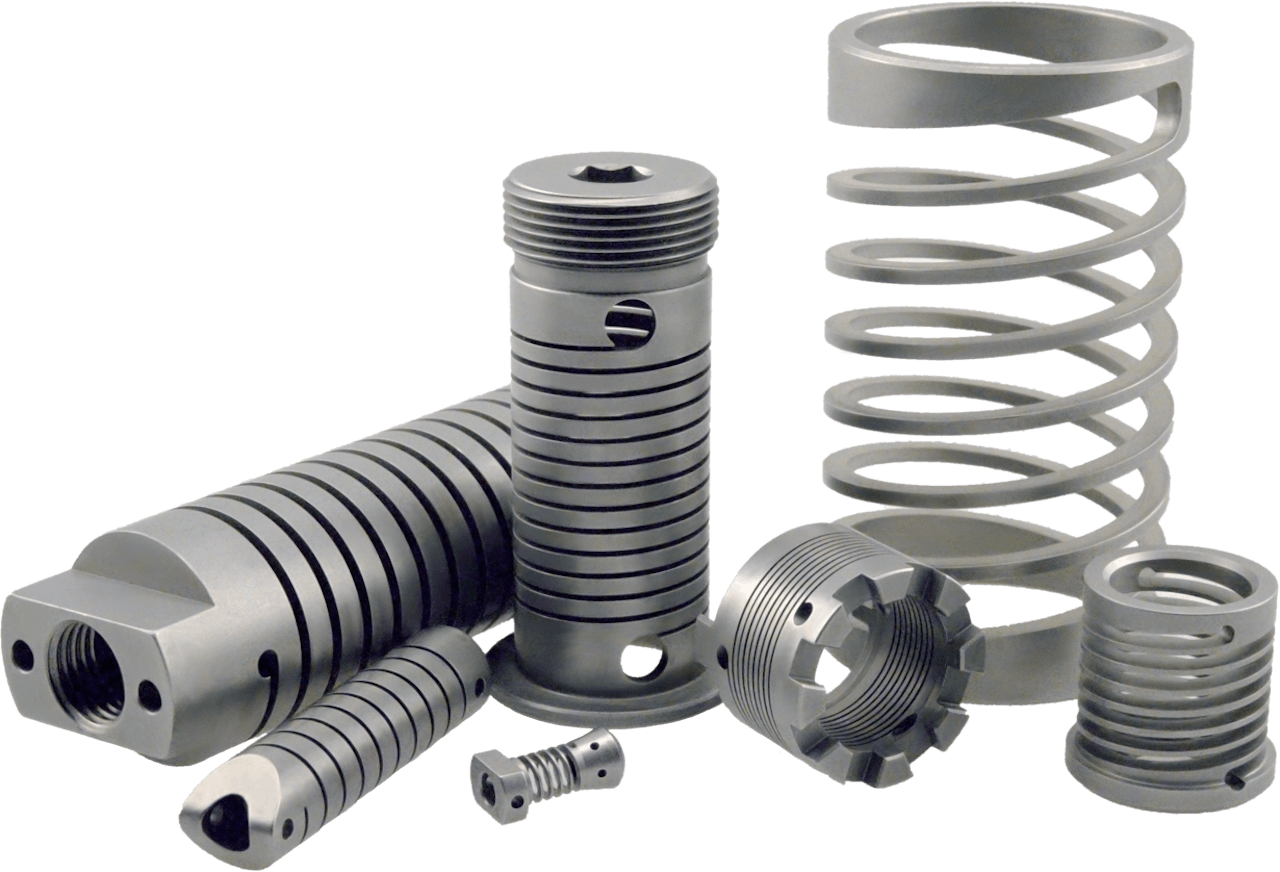

Helical Springs / Machined Springs

What is a machined spring? It is a single piece of material precisely designed and machined to have spring characteristics. Machined springs can be engineered to provide precise performance as compression, extension, torsion, lateral translation, or lateral bending spring. By producing rectangular coils with high aspect ratios, you can tailor a machined spring's performance characteristics to even the most exacting application requirements.

For more than 50 years, we have been providing machined spring solutions in various industries, including Aerospace/Aviation, Medical tools and equipment, Military, Energy, and computer and semiconductor manufacturing. Solving the most challenging and demanding requirements has been possible because of our expertise in designing and manufacturing machined springs in specialty alloys, including Inconel®, Titanium, Stainless Steel, and high-strength alloys like MP35N, Custom 455, and C300.

Helical Machined Springs Overview

Benefits

A key benefit of utilizing machined springs is the ability to machine attachment features into the elastic element and provide solutions not easily achievable by wire wound springs, especially in torsion applications. A machined spring design can also be engineered with more than one starting point to solve issues common to more traditional springs, such as squareness under load and lateral force.

Machined Spring Case Studies & Other Resources

CUSTOM MANUFACTURING

Custom Machined Springs

The integration of flanges, geometric shapes, bearing or valve seats, gears, splines, internal and external threads, and other machinable shapes are all available to design a machined spring. By eliminating the need for additional assembly components, a flexure component can save time in handling, provide added reliability, ensure more accurate and linear spring rates, and be held to more precise dimensions. Our team of Application Engineers is ready to assist in designing a machined spring to your specific requirements.

Because our springs are machined for a specific application and purpose, there are no stock machined springs. Applied to either high-precision applications or commercially graded needs, the versatile HELI-CAL Machined Spring®, aka Helical spring, provides superior elastic performance in a wide variety of applications. Machined springs can be designed to specifically address requirements for rate, reactions at desired deflections, combined rates, modal properties, weight, inertial limits, and more. Our springs can also support such design objectives as reliability, repeatability, and multiple-part integration.

Request a quote to configure a custom part.

Want to See the Machined Spring in Action?

Machined Springs Manufacturing & Configurations

No company has mastered the art of machined springs like MW Components. We are proud to say that one of our locations created the initial concept of the Helical spring; as such, we have developed proprietary equipment to enable unlimited geometric versatility and have a staff of application engineers to assist in designing machined springs for any application.

Want to experience this product for yourself? Request a prototype.

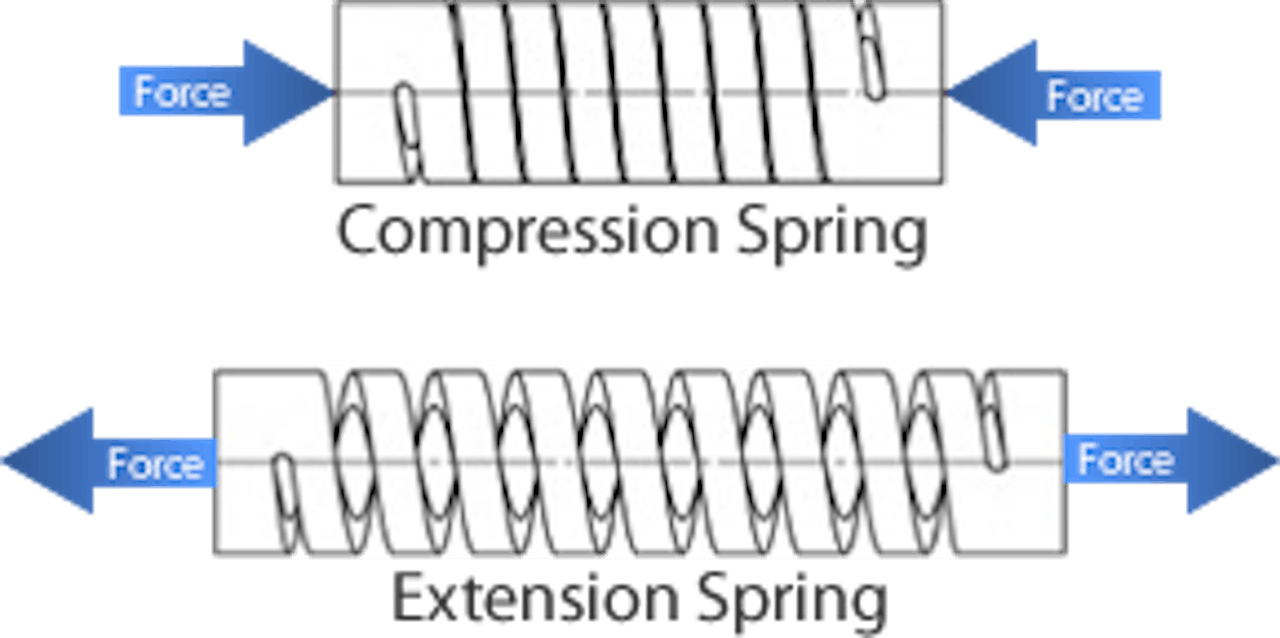

Compression & Extension Springs

- Load case: Compression & Extension

Helical springs (machined springs) provide very repeatable and linear, axial spring rates because of the absence of residual stresses often associated with traditional wire-wound springs. A significant advantage of the HELI-CAL Machined Spring® is the ability to provide multiple-start Flexure (coil) configurations. Using the multi-start configuration (normally Double or Triple Start) the unresolved moments common to single-start springs will prevent tipping or the application of side loads during compression or extension. One additional benefit of the multi-start coil configuration is it provides a level of system redundancy because more than one coil is transmitting the load. Another feature is the ability to combine a right-hand and left-hand Flexure in a single piece to prevent rotation that many types of springs exhibit during compression and extension. The ability to incorporate custom machined features as part of a single piece elastic component makes our Machined Springs a perfect solution for today’s demanding applications.

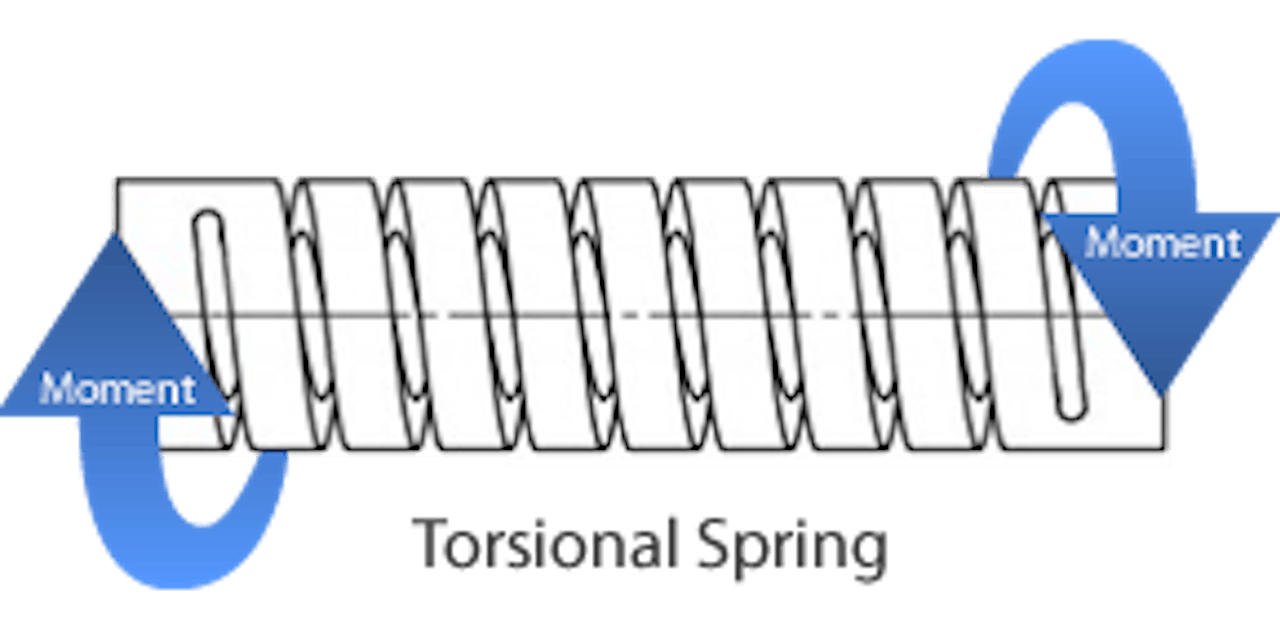

Torsion Springs

- Load case: Torsion

Endless design options are possible with the HELI-CAL Machined Spring® when applied to the torsional load case. Because attachment features can be integrated into a single-piece spring, the traditional challenges of how to transfer torque into a torsion spring will no longer be a concern. It is now easier than ever to use the versatility of integrated features to enable a Pure Moment in your torsion spring application. Gain smoother operation and added value by making a feature-rich HELI-CAL Machined Spring® the solution to your design requirements. With linear rates and the potential for rate accuracies approaching 1%, outstanding performance will set your design above the rest.

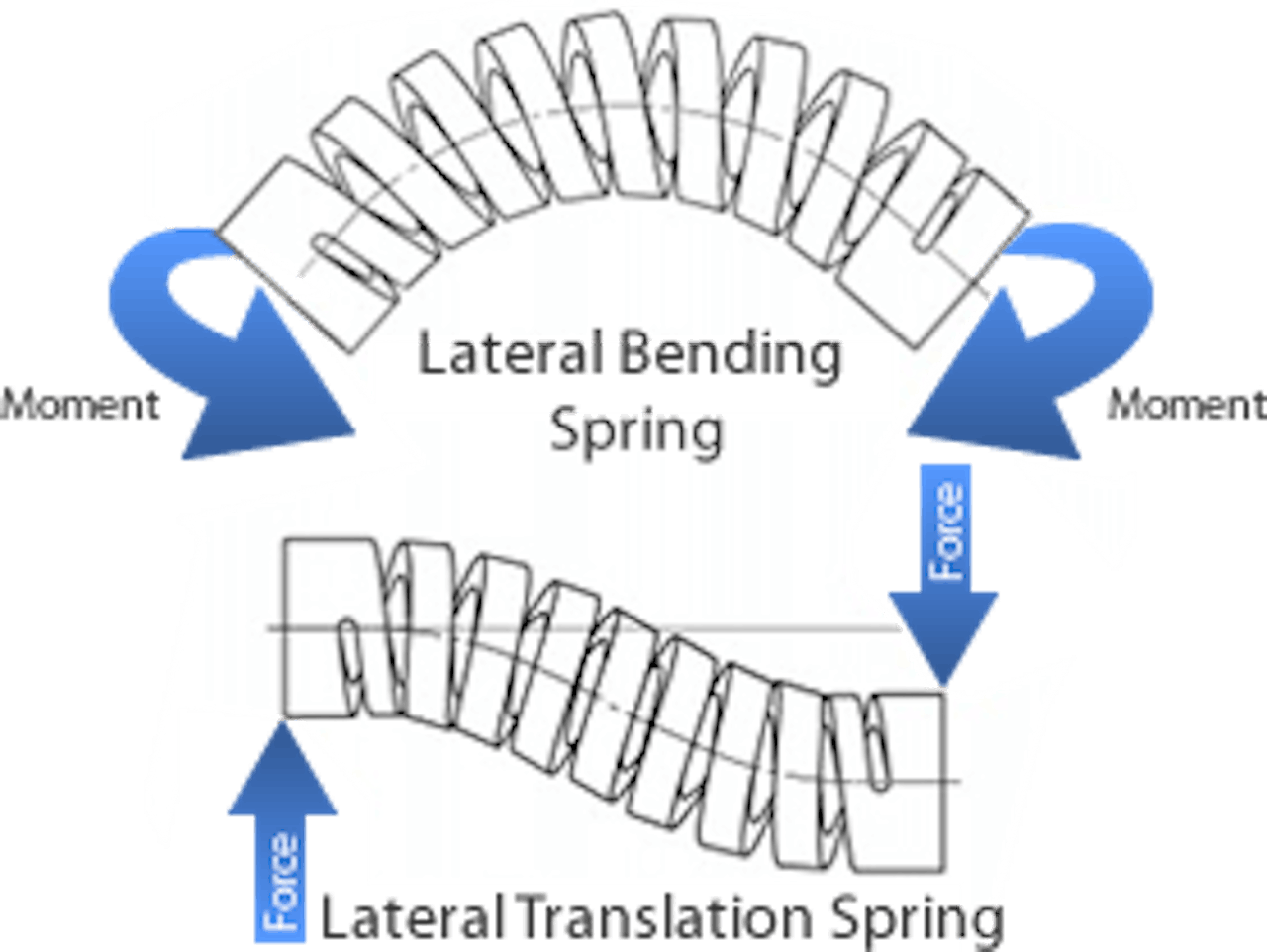

Lateral Springs

- Lateral Bending & Translation

Additional benefits of the HELI-CAL Machined Spring® can be realized in applications beyond the normal compression/extension or torsion load cases. The engineering staff at MW Components can apply their expertise in Engineered Elasticity to spring designs involving Lateral Bending and/or Lateral Translation applications. Lateral Bending is the result of anchoring at one end and applying a Moment to the opposite end. Lateral Translation occurs when one end of the spring is anchored and the other end has a Force and Moment applied to the other end so the ends remain parallel during displacement.

Leveraging the Machined Spring’s ability to provide both pre-determined elastic performance and integrate attachment features, all in a single piece enables significant design possibilities with the same reliable and repeatable performance that MW Components products are known for. The integrated attachments facilitate the anchoring of the spring and subsequent applying of Forces and/or Moments with unprecedented ease. Changing the outside or inside diameters, as well as the number of starts, the number of coils, and coil width, make it is possible to provide desired spring rates in different axis of displacement.

Materials

MW can produce machined springs from several materials. From Custom 455® and other specialty alloys to engineered plastics like Delrin 150, we stock various standard and specialty materials to ensure that we are here for you whatever your project and desired composition.

Related Manufacturing Services

Machined springs can be designed to specifically address requirements for rate, reactions at desired deflections, combined rates, modal properties, weight, inertial limits, and more. We offer design, tooling, and prototyping assistance to ensure that each component we produce is designed exactly to your desired specifications.

Quality Standards & Certifications

With certifications in ISO9001/AS9100, a customer-centric philosophy, outstanding quality, and customer service, our team of 125+ employees can provide your application the Engineered Elasticity solution that will set you apart from the competition.

Our Manufacturing Locations

Have Questions?

Talk with one of our engineers or specialists today and let us help you figure out the best solution.