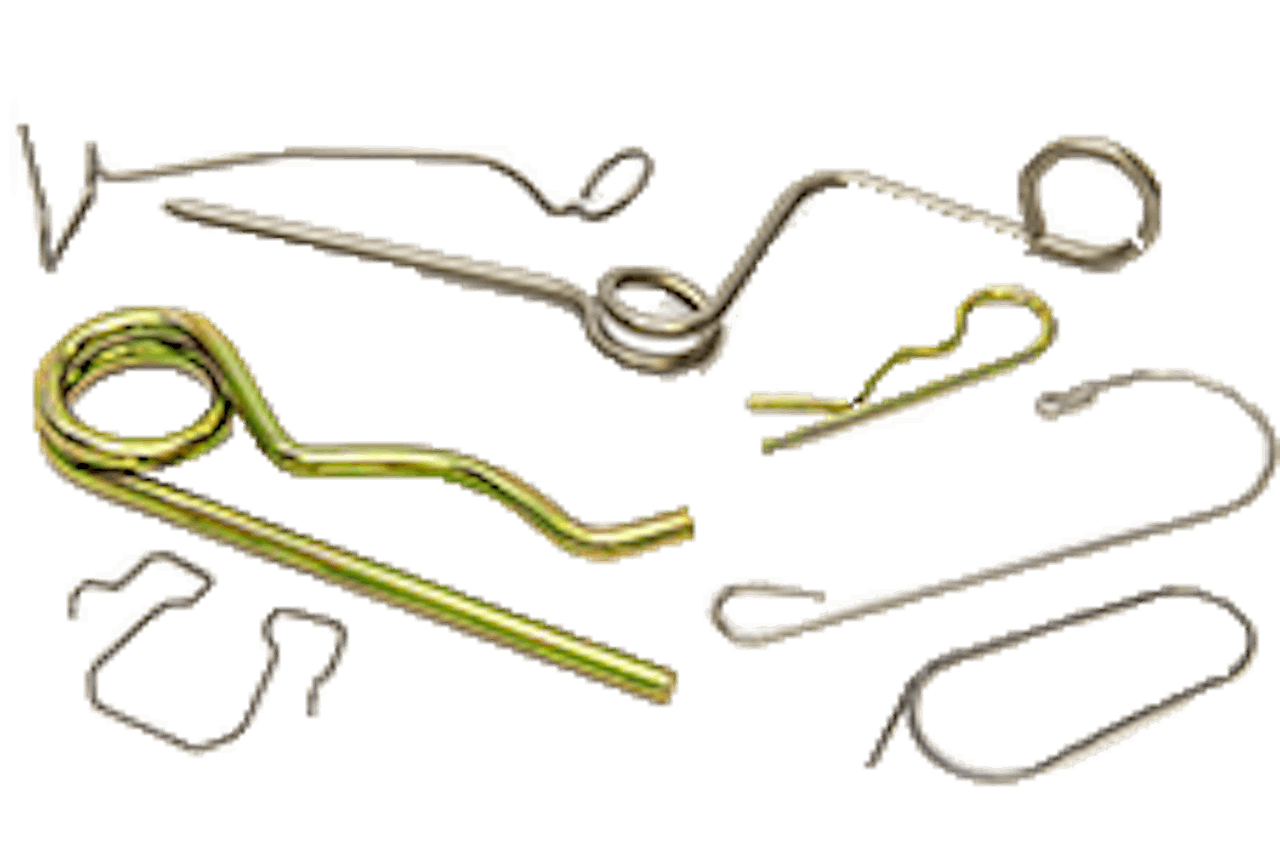

MW Components manufactures custom retaining rings, also known as coiled rings, snap rings, round wire rings, circlips, square section rings, rectangular section rings, custom-shaped sections rings, or tapered section rings. Our snap rings are available in various end configurations for use in multiple applications.

There are two main types of snap and retaining rings—internal retaining rings, which are assembled inside a cylinder where the ring fits inside a hole (or bore), and external retaining rings, which are assembled on the outside of the shaft.

Quality & Service You Can Trust

"Excellent service. I appreciated the team being willing to work with me when I walked in the door. Best of all my order was delivered earlier than the initial estimate."

- Thomas Hill, Contour Forming

CUSTOM SNAP RING MANUFACTURING

Custom Retaining Rings

MW Components produces both internal retaining rings and external retaining rings from various materials for multiple applications and industries, including aerospace, agriculture, automotive, valves, industrial automation, and consumer products.

With 25+ specialized manufacturing facilities across the United States, we stock both industry-standard and specialty materials, including carbon steel, phosphor bronze, chrome silicon alloy steel, stainless steel, and others. In addition to working with a variety of materials, our engineering and manufacturing experts work with state-of-the-art machinery capable of producing snap rings in a variety of end configurations and sizing options, giving you a multitude of customization options for a specialized component.

Retaining Ring Types

As a leading retaining ring supplier, MW Components provides unrivaled dedication to both quality and selection. We manufacture retaining rings with the end types below, as well as custom build-to-print designs. Whether you need unique ends for your coiled rings or a custom snap ring design, we can help.

-

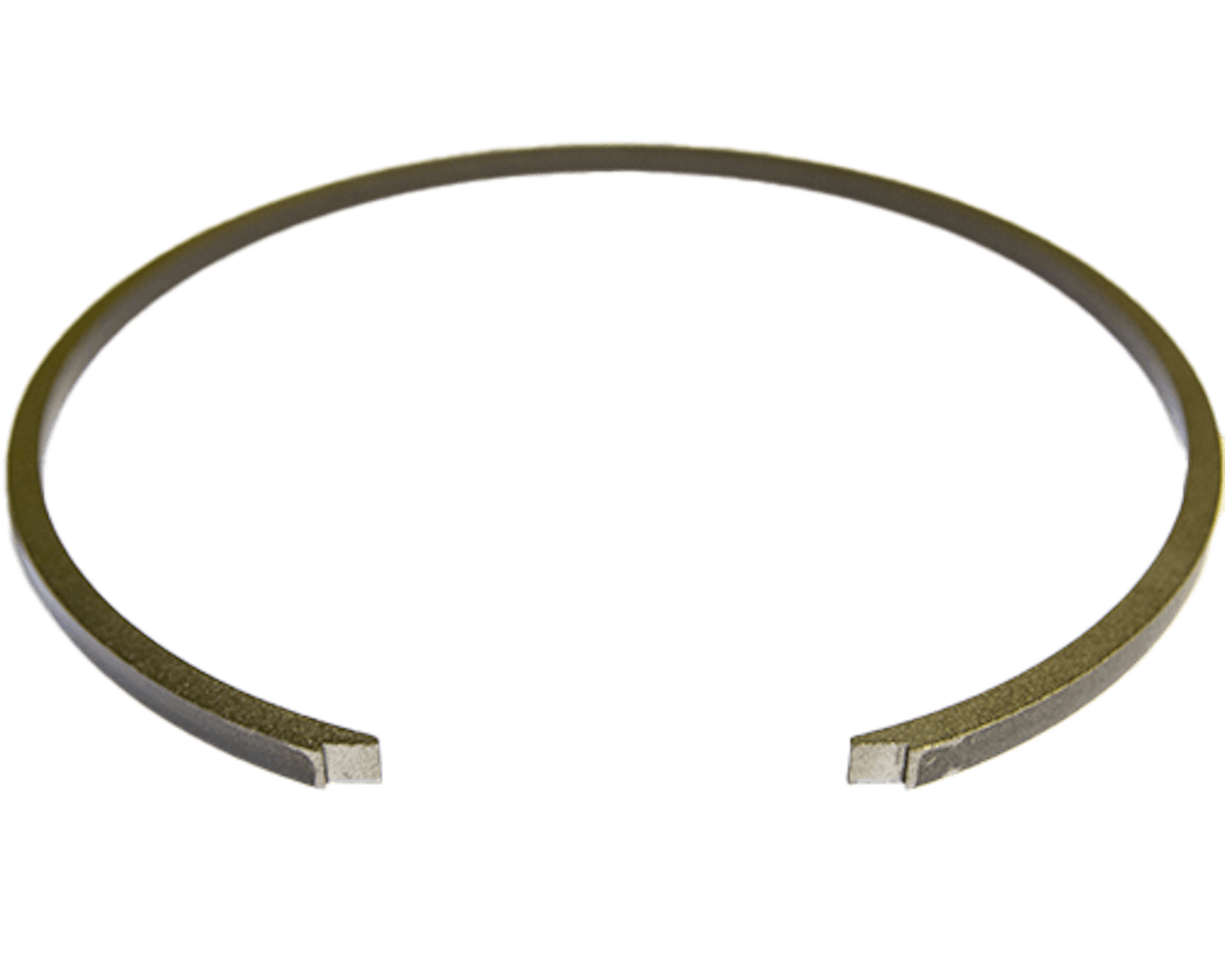

Straight cut ends

Straight cut ends -

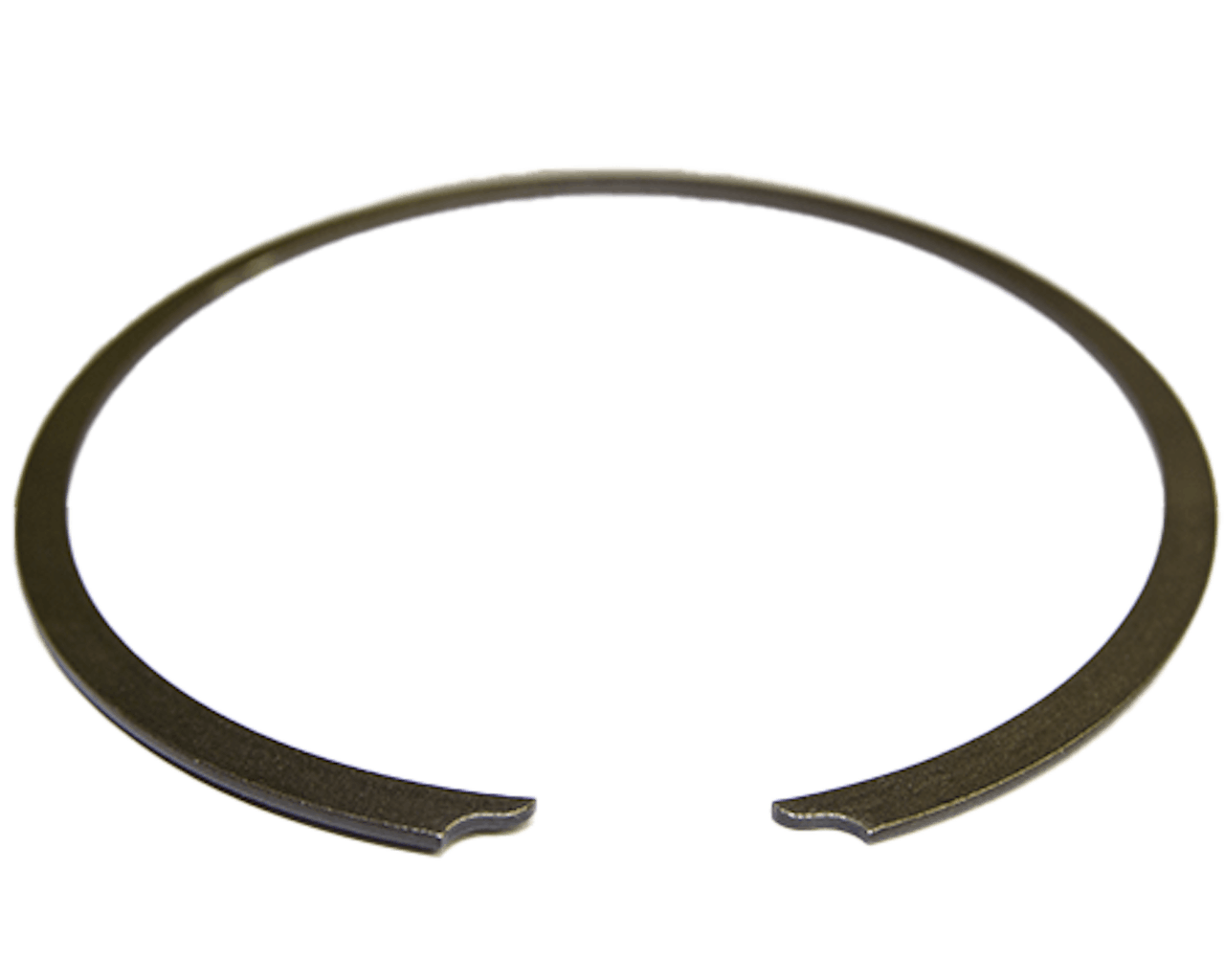

Rounded ends with ID notches

Rounded ends with ID notches -

Straight cut ends with OD notches

Straight cut ends with OD notches -

Round wire retaining ring with angle cut end

Round wire retaining ring with angle cut end

-

Dubb cut ends

Dubb cut ends -

Reverse angle cut ends with slight dubb cuts

Reverse angle cut ends with slight dubb cuts -

Custom shaped and formed ends with holes

Custom shaped and formed ends with holes -

Custom formed ends

Custom formed ends

-

Custom shape cut ends

Custom shape cut ends -

Butterfly cut and straight cut ends

Butterfly cut and straight cut ends -

Butterfly cut ends

Butterfly cut ends -

Angle cut ends

Angle cut ends

Product Overview: Snap Rings & Retaining Rings

Characteristics of Retaining & Snap Rings

Retaining rings are designed for use on shafts or in bores. The ring is installed into a groove, thereby creating a shoulder to accurately position and retain other assembly components. The retaining shoulder is created when the ring attaches itself to the bore or shaft, typically by snapping into a groove. For more information, download the brochure.

Benefits of Retaining Rings vs Traditional Fasteners

The advantages of using retaining rings include their ease of assembly, low manufacturing cost, and positioning accuracy compared to traditional fasteners. Retaining rings only require a groove. This advantage over traditional fasteners requires threaded components, mating threaded holes, access holes, and counter-bores. Retaining rings function with a minimal amount of surface preparation to either the shaft or the housing.

Retaining Ring Manufacturing

We manufacture industrial retaining rings, snap rings, circlips, and more for a variety of applications. Whether you're in the automotive industry or working in military & defense, we can help you get the coiled ring you need, on the timeline you need it. Get more details on our retaining ring manufacturing capabilities below, or contact us for information on specialty processes and services.

Wire Shapes

Our manufacturing team has experience working with some of the most diverse wire shapes in the industry, making us a premier retaining ring supplier in the US.

Materials

Our retaining rings can be made from a range of materials. If you don't see your material below, contact us. With a nationwide supplier network, we can support most custom requests.

Secondary Processes

We offer many secondary processes in-house and have the ability to support outside services as needed for your project.