Elgiloy

Corrosion-Resistant Super Alloy

Elgiloy® is considered a “super-alloy” consisting of cobalt, chromium, nickel, iron, molybdenum and manganese.

Grades / Attributes

Elgiloy is used to make springs that are corrosion resistant as well as provide high strength, ductility and good fatigue life. Elgiloy is highly resistant to sulfide stress corrosion cracking and pitting, and can operate at temperatures up to 850°F.

Spring Applications

Oil and gas in a wellbore environment is probably one of the largest applications for Elgiloy springs because the alloy is highly resistant to corrosion cracking in chlorides. It is also used in aerospace applications where high strength and temperature resistance is required. Other applications include springs for medical and dental products.

Material Benefits

Alternative material for Inconel X-750, if upgraded performance is required. Elgiloy will provide more strength in a small space than Inconel X-750 and MP35N.

Considerations

Cost can be prohibitive if the performance requirements do not merit its use.

Custom Elgiloy Parts

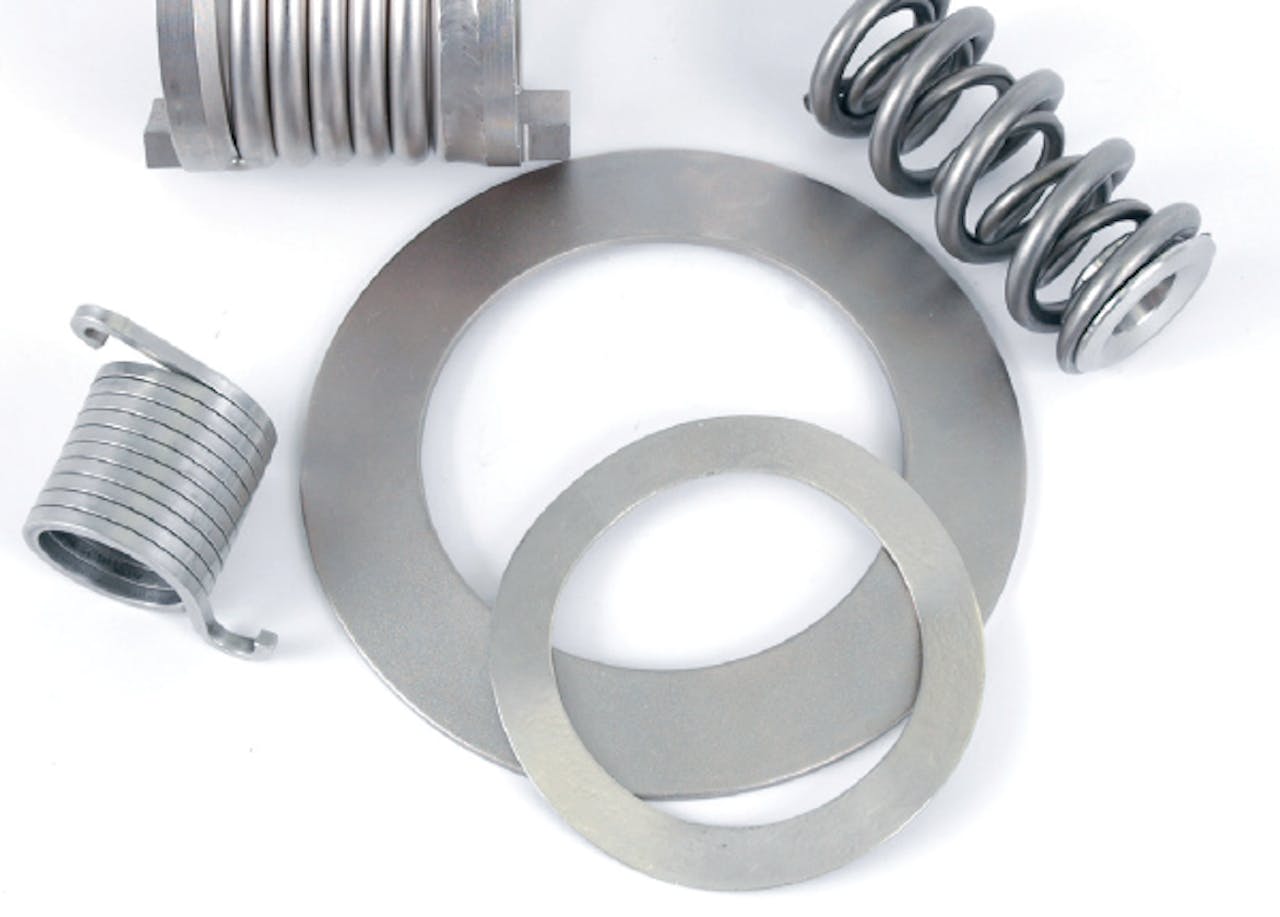

We manufacture custom Elgiloy springs and other Elgiloy parts from wire and strip material. With decades of experience, our expert team works with your engineers to review product drawings and control manufacturing so you get the Elgiloy parts you need, especially for difficult applications such as those that have severe service requirements. Our Elgiloy products include custom springs, compression springs, garter springs, flat or bow springs, Belleville and disc springs, stampings, and more.

For more details or to work with one of our engineers to solve a complex problem, contacts us using the below form.

Contact Us

Need more information on stock or custom elgiloy springs and other elgiloy parts? Contact us. We'll make sure you get to the person best able to support your needs.