Spring Energizer Products

Spring energizers are generally used to overcome the load constraints of a polymer seal jacket. Though polymers offer great sealing capacity, they lack consistency in load distribution. Energizers housed inside the polymer jacket are used to overcome variations in pressures, temperatures, and surrounding component tolerances, providing more consistent performance.

MW Components is a trusted supplier of spring energizer products worldwide through our Kemah, TX location. Some examples of our spring energizer products include V-springs, helical springs, full-contact springs, slant coil springs, and Q-connect slant coil springs.

After years of manufacturing excellence, we can create hundreds of cross-sections without the need for more costly tooling. We have invested in equipment and services that increase our products' quality and offer more value to our customers. Some examples include varied tooling capabilities, Swiss-made high-speed milling machinery, Load-Deflection Testing, laser welding, and 3D modeling software. For more information on Spring Load vs. Deflection, visit our information page.

CUSTOM MANUFACTURING

Custom Spring Energizers

In addition to standard sizes, we also have over 100 different cross-sections of cantilever U and V springs available with little to no tooling cost to you. We can provide the exact quantities you need, reducing your investment in excessive inventory. With over 30 facilities worldwide, our combined material purchasing power ensures that we can stock specialty materials that are expensive and generally require longer lead times with other manufacturers. Having these alloys ready for production allows us to offer the best price and shortest lead times available. That's why so many leading companies choose MW Components.

We also perform spring energizer welding in-house. Review Features and Benefits of Welded Springs vs. Non-Welding Springs, to determine which is right for your application.

Request a quote to send us your specs or configure a part.

Spring Energizer Manufacturing

We work with the highest quality alloys and the most knowledgeable spring manufacturing experts in the world. Working with us, you should expect to avoid high minimums, long lead times, and expensive tooling costs while enjoying our extensive variety of optional manufacturing services.

Materials

MW stocks standard and specialty materials of all types. Below are some commonly requested materials used to manufacture spring energizer products. If your application requires alternate materials, contact us for custom quote information.

To review more information about spring energizer materials, including options, features, and availability, click here.

Related Manufacturing Services

MW offers many optional secondary machining and finishing services for this product type. If you need additional services, contact us for more details.

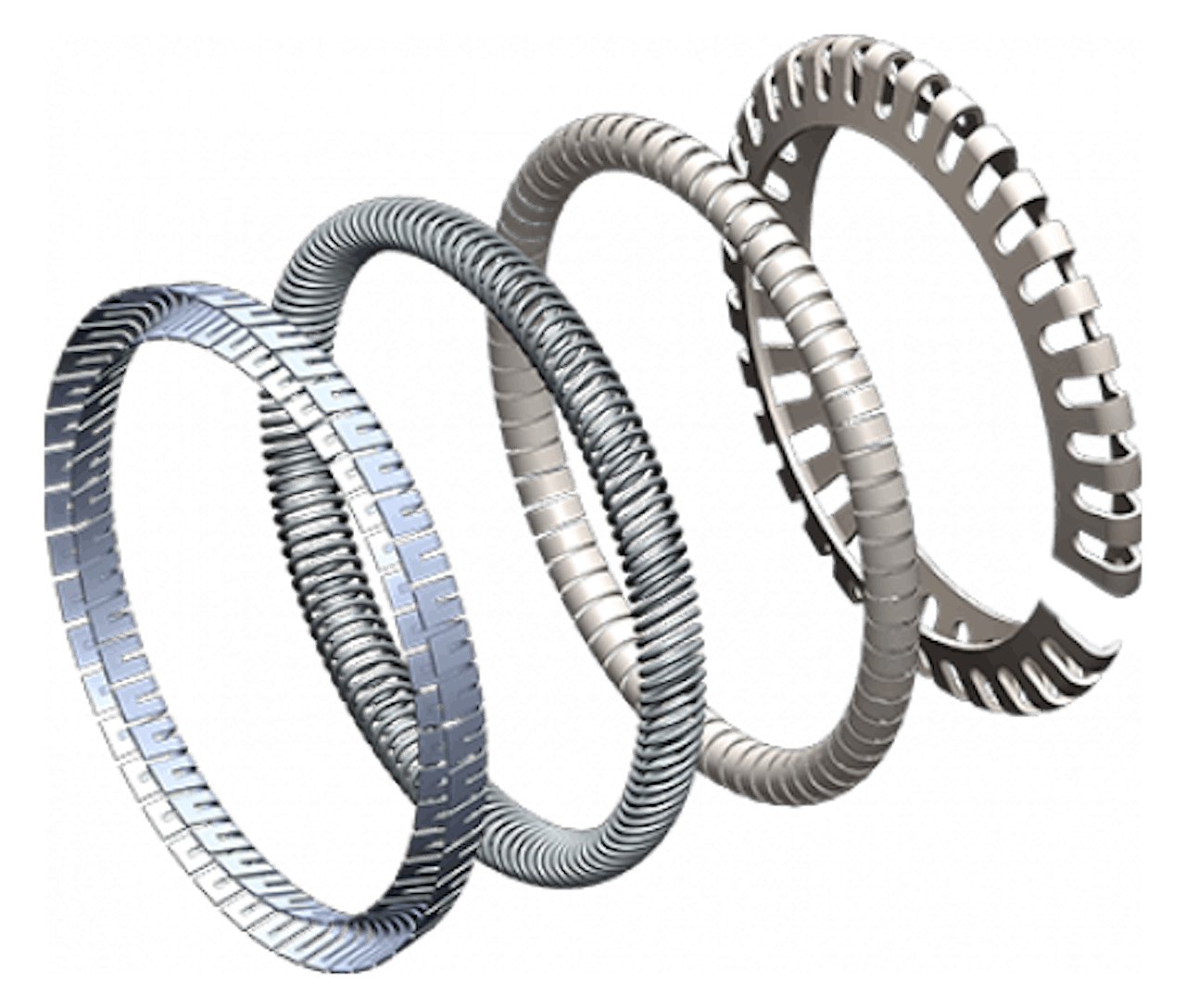

Spring Energizer Configurations

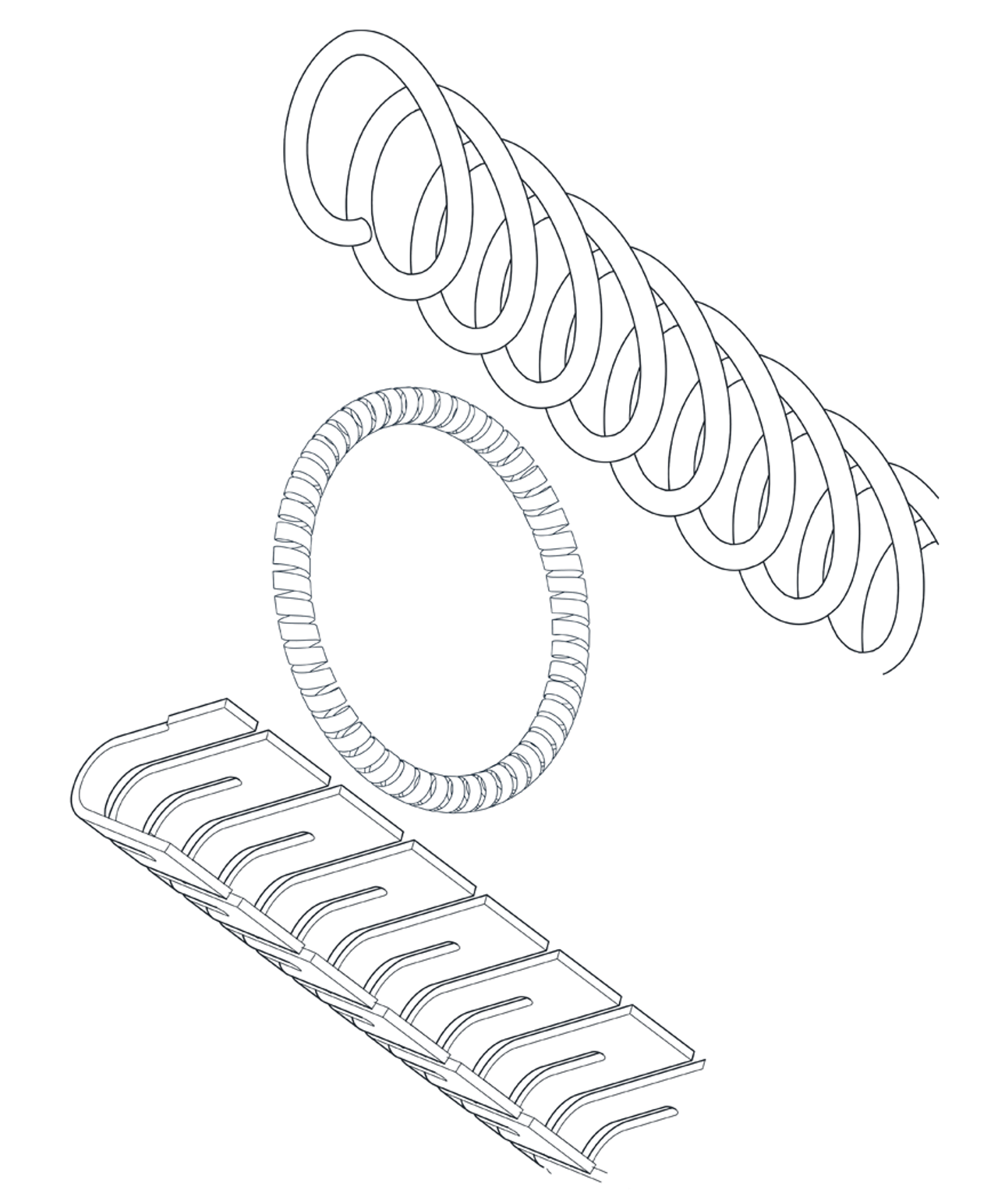

V-Spring

The V-Spring is a versatile spring energizer that can be used in multiple applications. It is considered the standard for spring energizers. It is widely used to assist in sealing applications for oil and gas due to its greater deflection range and the fact that it can be produced using Elgiloy (a non-corrosive material). This spring generally withstands temperatures ranging from -75 to 500 F and pressures above 30,000 psi, making it a great option for many sealing applications.

View Features & Load Deflection Comparison Between Spring Types

Helical Spring

The Helical spring can withstand high loads with low deflection and is ideal for static applications or those requiring tight seals. Common applications for the Helical Spring may include end caps for pumps or compressors or bubble-tight face seals within pressure vessels. This spring can even be used for cryogenic purposes since it withstands temperatures down to -320 F. For tight or static seals, this spring is the optimum choice.

View Features & Load Deflection Comparison Between Spring Types

Slant Coil Spring

The Slant Coil spring is one of our more unique spring types. It has a flat load to deflection curve which means that the force emitted stays constant over a wide deflection range. This feature makes it perfect for high-speed rotary systems or applications which require tight control of running friction or breakout. It may also be used within devices that require a quick disconnect where many engagement and disengagement cycles are necessary.

View Features & Load Deflection Comparison Between Spring Types

Full Contact Spring

The Full Contact spring, also called FC spring, can withstand the highest load and maintains a higher deflection range than the Helical spring. Continuous ribbing along the outer edge allows it to energize the seal while also acting as an added structural component inside the seal, which allows it to fight the thermal contraction of the seal jacket when exposed to extreme temperatures. Due to its configuration, the Full Contact spring can only be used in axial applications.

View Features & Load Deflection Comparison Between Spring Types

Questions about our Spring Energizers?

Contact us. Our staff includes sales professionals who can help with pricing along with design engineers and manufacturing experts who can answer even the most difficult technical questions. Get in touch for questions about spring energizers or any of our other products, and we'll make sure you're connected with the person most qualified to help.