Rivets

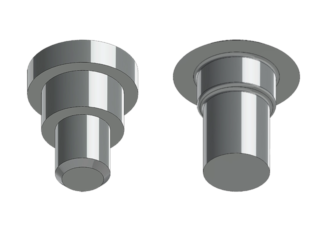

Solid Body Rivets and Semi-Tubular Rivets

MW Components offers custom rivet manufacturing in a variety of sizes and styles. Our top rivet products include solid body rivets and semi-tubular rivets.

Solid body rivets, or solid body shoulder rivets, provide a quick and inexpensive solution to join workpieces while allowing for rotation of the riveted joint. They act as a bearing surface when the rivet shank is secured to the non-rotating part of the assembly. They are useful in many settings and are often found in automotive assemblies, scissor lift assemblies, and furniture manufacturing, to name a few.

Semi-tubular rivets offer a 12 point design with up to 21% greater clamp load in an equal size head. Using the cold forming method, this 12 point bolt can be crafted from a variety of materials. Semi-tubular rivets are great for high pressure applications such as turbines, utility infrastructure, and engines in the agriculture, automotive, construction and infrastructure, energy, and transportation industries.

CUSTOM MANUFACTURING

Custom Rivets

MW Components specializes in custom manufacturing for a variety of fasteners, including solid body rivets and solid body shoulder rivets, double end rivets, semi-tubular rivets, and many more. We produce rivets in sizes ranging from 0.125" - 0.650" (3.5mm - 17mm) and various lengths depending on your specified rivet configuration.

Our facilities offer an array of custom machining and forming capabilities as well as optional finishes and coatings. We even offer in-house design and engineering assistance, CAD modeling, and prototyping to ensure that the fastener produced for your application performs at or above the standard that your application requires.

Request a custom quote to send us your specs or configure a part.

Rivet Manufacturing

MW Components manufactures solid body rivets in a range of sizes, lengths, and material compositions for various industries and applications. Our facilities use state-of-the-art machinery, and advanced design and engineering tools, including camera and optic vision systems for sorting and quality assurance. To further ensure performance in critical applications, we maintain industry-specific certifications like ISO 9001, and ITAR compliance, among others.

Our facilities combined also employ over 100 design and engineering experts with decades of experience spanning multiple industries including agriculture, construction, consumer goods, industrial, automotive, oil, gas, renewable energy, and others. This means you can rest safe in the knowledge that the parts we produce will meet or exceed your requirements consistently.

Solid Body Rivet Specifications

Diameters:

- Standard: 1/8″ – 1/2″

- Metric: 3.2mm – 12.7mm

Lengths:

- Standard: 3/16″ – 3″

- Metric: 5mm – 76mm

Semi Tubular Rivet Specifications

Diameters:

- Standard: 1/8″ – 1/2″

- Metric: 3.2mm – 12.7mm

Lengths:

- Standard: 3/16″ – 3″

- Metric: 5mm – 76mm

Manufacturing Process Capabilities

MW Components produces custom components of all types using a variety of machining, forming, and finishing methods. Some examples of our fastener manufacturing capabilities include the below.

Visit our Manufacturing Services Page to find a complete list of MW Components' manufacturing processes and capabilities.

Have Questions?

Talk with our experts today and let us help you figure out the best solution.

Other Fastener Products

Our Manufacturing Locations

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.