Products > Bellows / Couplings

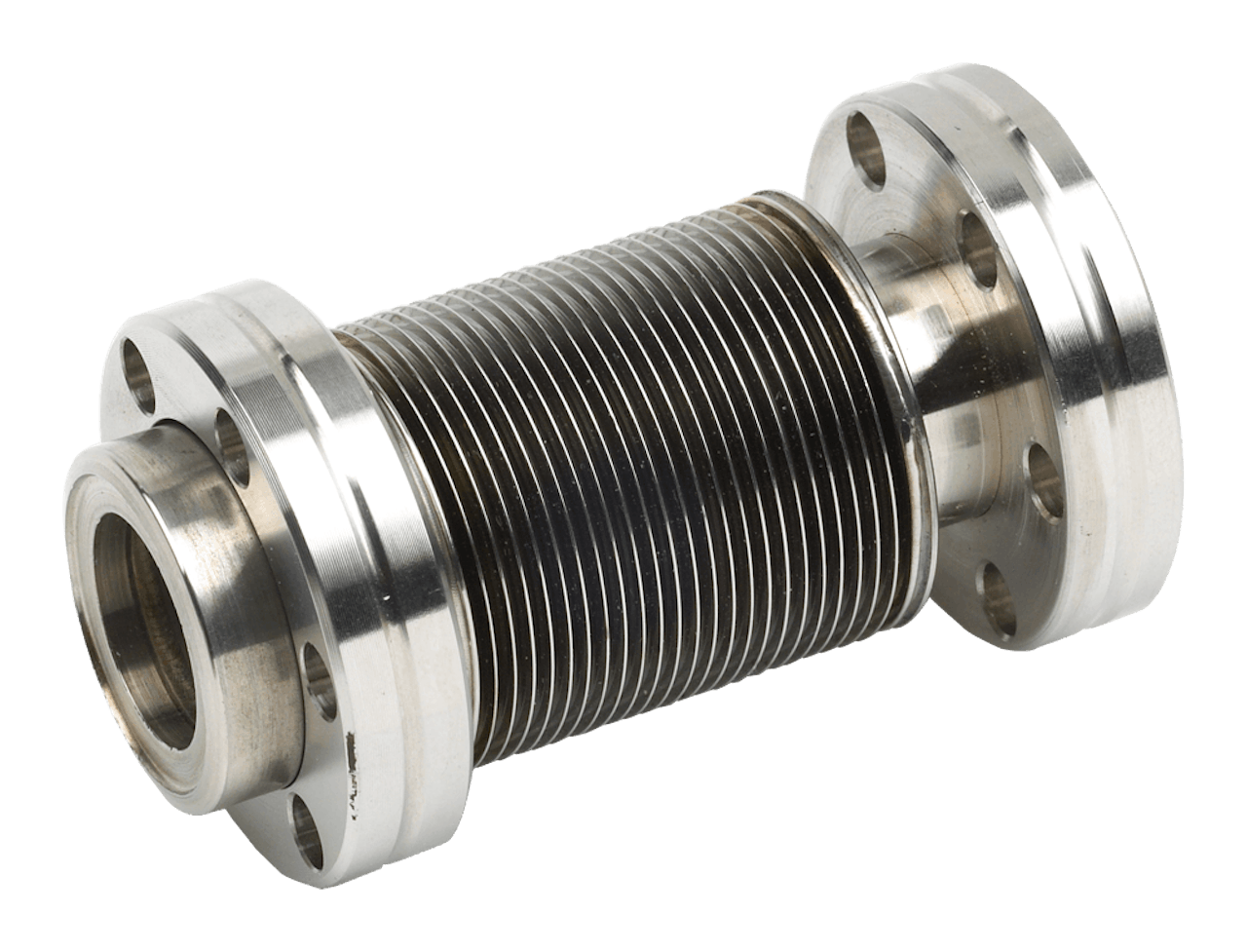

Edge Welded Bellows

MW Components’ edge welded metal bellows provide the most flexibility in the smallest amount of space of any bellows technology on the market. Edge welded metal bellows are engineered to allow for maximum flexibility in axial, angular, and parallel offset motion. They provide a hermetic, all-metal pressure barrier and seal that flexes in one or more directions as well as:

- Outstanding resistance to corrosive or harsh environments

- High-temperature endurance

- Excellent media compatibility

- Ultra-rugged construction for maximum durability

- Up to 90% stroke length

- Standard precision bellows or custom one-piece designs

- Optional end pieces

Ready to buy or need a quote? Use the custom bellows design form to give us the details and we'll get in touch.

Or contact our engineering team if you have questions.

All Edge Welded Bellows

CUSTOM MANUFACTURING

Custom Edge Welded Bellows

Have special requirements? Need a unique end piece or guide? We manufacture custom edge welded metal bellows and even provide expert design and engineering assistance. Consult with one of our design engineers for a completely unique bellows that meets all your pressure, temperature, or movement specifications.

Send us your specs or configure a part.

MW Components' Edge Welded Bellows

MW Components manufactures standard and custom edge welded bellows that are designed to support critical applications. We offer:

- Proprietary stamping, cleaning and welding techniques for exceptional strength and consistency

- Individually inspecting diaphragms for the highest quality to ensure welds are the strongest and leak-tight

- Special handling to protect against contamination of the materials

- Deep penetrations and consistent weld bead geometry to ensure a leak-tight joint that can withstand high-cycle applications

- Engineered for optimal performance with an internal vacuum or external pressure

- Optional heat treating to strengthen the material

- Helium leak testing to industry standards (1×10-9 for stainless steel material) to ensure the assembly is completely sealed.

- Lower leak rates are available as required

- Over 90 standard bellows sizes, round and non-round shapes

Our edge welded metal bellows are typically manufactured from sheet stock. We offer various materials of construction to suit your application including:

- AM350

- Stainless Steel (316L, 304L, 347)

- Inconel ( 625, 718)

- Hastelloy•(276C / Haynes 242)

- Titanium ( Grades 1 – 4) (ASTM_B265)

Material thickness range from .0015” to 0.20” depending upon the die size while outside diameters range from 0.358” (9.09mm) to 26” (660mm) and inside diameters range from 0.125” (3.175mm) to 23.2” (648mm). The choice of material type is often dependent upon other properties such as temperature and leak tightness. Other material characteristics to consider include weight, cycle life and corrosion resistance. Consult with one of our design experts (this should be a link here to technical assistance) to help you choose the best material choice to fit your application and your budget.

To achieve optimum movement in vacuum and positive pressure environments, we manufacture our bellows to the precise requirements specified by our customers in the Oil and Gas, Semiconductor and UHV industries where mechanical movement is the most frequent requirement.

Are Edge Welded Bellows Right for Your Application?

Not sure if edge welded bellows are right for your application? Use our Metal Bellows Comparison Chart to see how edge welded bellows compare to electrodeposited and hydroformed bellows.

Standard Edge Welded Bellows Sizes

MW Components offers more than 90 standard diaphragm sizes. View the full list of available sizes to find the best option for your project.

Metal Bellows Material Selection Guideline

Our edge welded bellows are available in a wide variety of materials with a range of media compatibilities. Use our material selection guide to find the right material for your requirements, at the right price.

Applications

MW Components manufactures standard bellows and custom edge welded bellows for a variety of applications. Learn more about some of the most common uses for our bellows and available specifications for each.