Die Springs

MW Components is a leading US-based spring manufacturer. MW offers several die springs in both oil-tempered and chrome-alloy materials. Die springs are used primarily in die machinery. However, they are also well-suited for many applications where high-static or shock-load stresses are required or when maximum cycle-life is needed.

Die springs are used primarily in die machinery. However, they are also well-suited for many applications where high-static or shock-load stresses are required, or when maximum cycle-life is important. Rectangular wire is employed to reduce the solid height and increase the space efficiency of the design. We produce die cut springs using both round and rectangular wire.

CAD files for stock and standard die springs are available in our online store.

Die Springs Overview

Die Spring Characteristics

Century Spring has designed and manufactures a complete line of industrial die springs. Generally used in die machinery, they are well-suited for many applications where high-static or shock-load stresses are required or when maximum cycle-life is important.

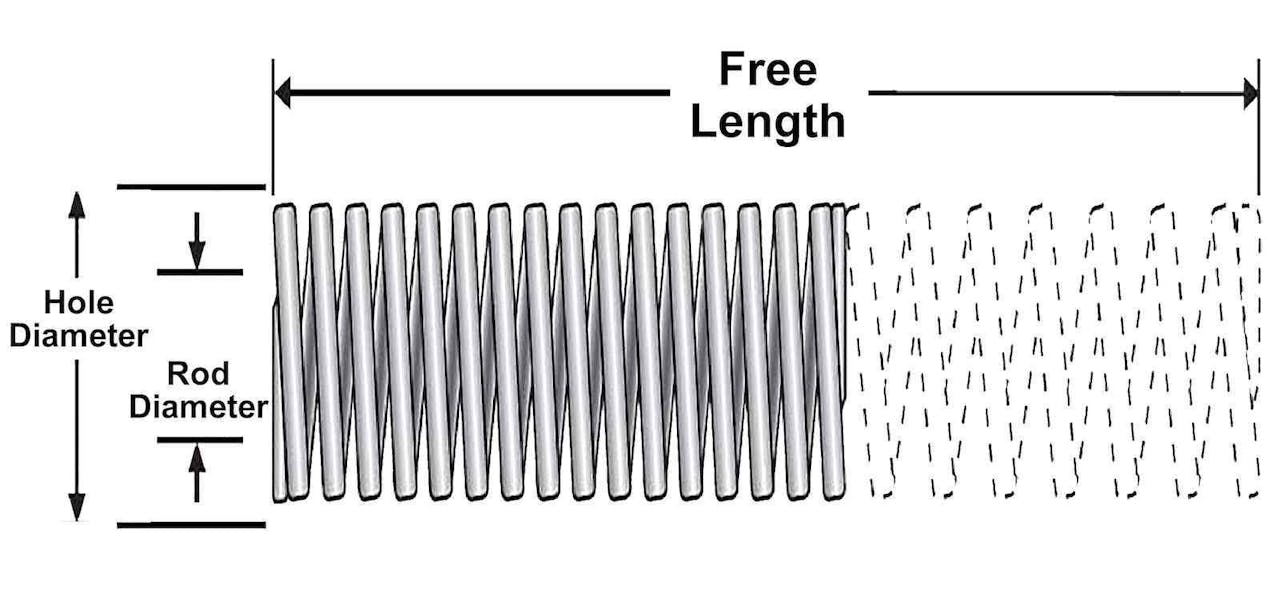

Hole and Rod Diameter

The die spring containment hole diameter sizes used in our online and print catalogs must be considered to eliminate possible spring-to-wall friction caused by heat, wear due to fabrication tolerances, and interference from the spring diameter growth due to compression. If the spring is long for its diameter, an internal supporting rod may be required to eliminate spring buckling.

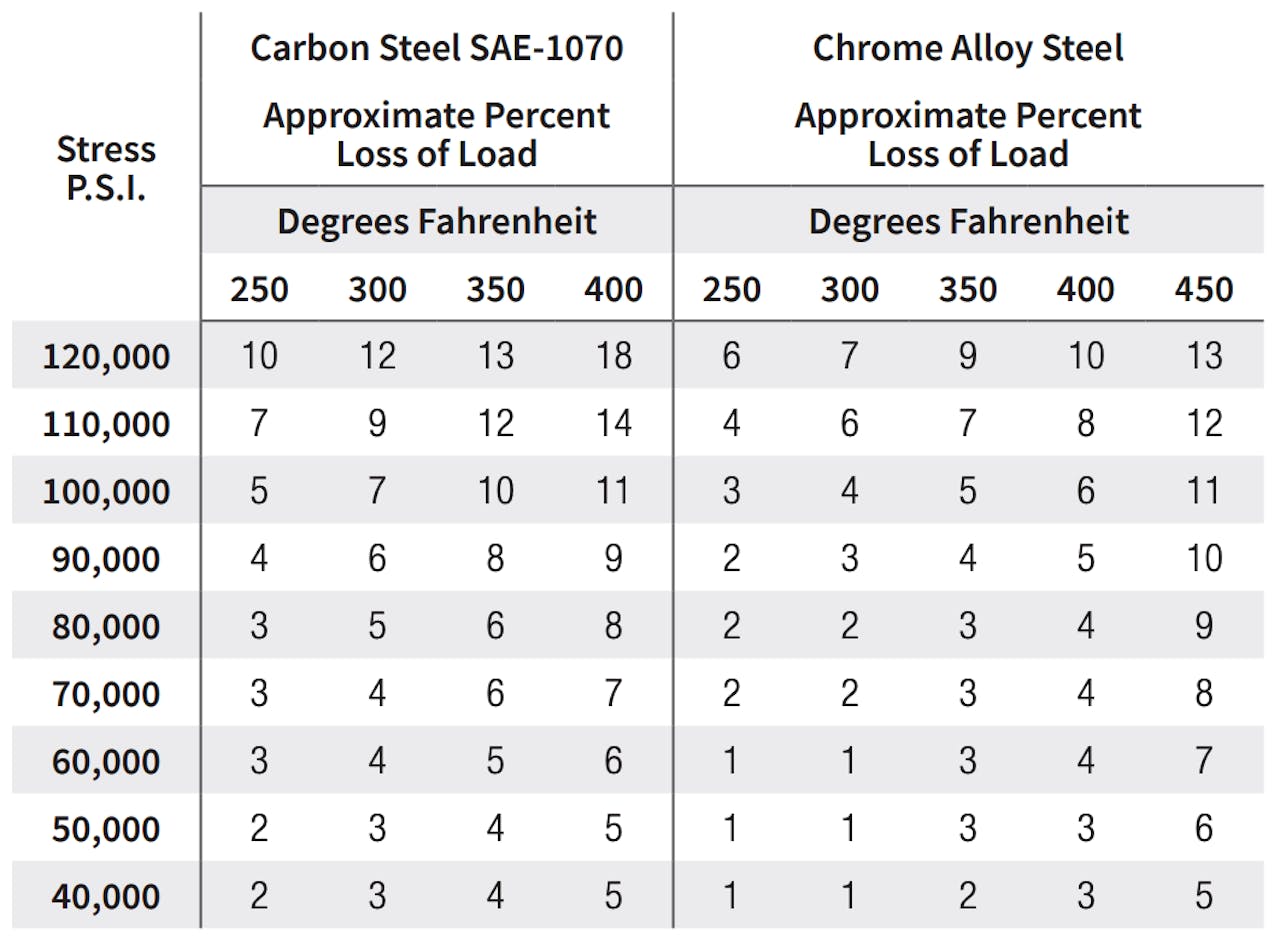

Heat

Thermal effects are frequently ignored in spring failure or load-loss analysis. The maximum rated service temperature for chrome-alloy steel is about 440° F. The following table reflects the approximate load losses due to heat that can be expected with die springs.

Measuring Die Springs

- Measure the Hole Diameter (also known as Outside Diameter)

- Measure the Rod Diameter (also known as Inside Diameter)

- Measure the Free Length (no load on the spring)

- Measure the Wire Size (both width and thickness dimensions)

- Use our search feature or catalog to find the correct color code and size for your needs.

For example, if a die spring measures .96″ on the hole dimension, it will fit into a 1″ hole. If it measures .56″ on the rod dimension, it will fit over a .50″ rod. Note: Die springs are manufactured to a “GO/NO-GO” dimension.

Service Life

All of our die springs are fabricated from the most efficient wire cross section, which is rectangular with rounded corners. The oil-tempered die springs are offered for die sets and general use at a reduced cost. A very long service life may be expected from oil-tempered springs if their maximum deflection is held to about 25% of their length. The highest grade of electrically-furnaced, shot-peened and preset chrome-alloy steel die springs are offered for unsurpassed quality.

CUSTOM MANUFACTURING

Custom Die Springs

We have several in-stock options for die springs available on our online store; however, if you find that none of these suit your specific needs, we are happy to customize an order to your exact specifications.

Send us your specs or configure a spring.

Die Spring Manufacturing

MW manufactures a variety of industrial die springs that are typically used in die machinery. Our die springs are ideal for applications that require high-static or shock-load stresses or when users need to maximize cycle-life. If oil-tempered springs are held to a maximum deflection of 25% of their length, you can expect a long service life.

Materials

Our die springs are fabricated from rectangular wire cross sections with rounded corners, the most efficient wire cross section available. Oil-tempered die springs are offered for die sets and general use at a reduced cost. For unsurpassed quality, we offer highest grade of electrically furnaced, shot-peened and preset chrome-alloy steel die springs.

Types of Die Springs

MW Components offers multiple types of die springs with varying measurement standards. These die springs are well suited to a variety of applications, including those with high stress and heavy loads. Die springs are available in oil-tempered and chrome-alloy materials and can be custom ordered with finishes such as powder coating or nickel plating.

Color Coding - Chrome Alloy

Die springs of oil-tempered material are only available as unfinished. Chrome-alloy die springs can be custom ordered with finishes such as powder coating or nickel plating. For unfinished die springs, a color-coding system is used for visual identification of the spring’s work range and to prevent errors in spring selection and installation. The color coding is a light coating of water-based paint.

Color Coding - Chrome Silicon

Our oil-tempered die springs are unfinished. We offer a color coding system of light coating of water-based paint. A thin coating of the pain is applied to make it easy to identify your die spring's work range, helping reduce mistakes in selection and installation.

Quality Standards & Certifications

At MW, we pride ourselves on creating quality products that meet or exceed industry standards. Not only do our facilities perform rigorous quality assurance testing to your specified ranges, but we also maintain several key certifications to ensure that only the best products are shipped to you.

Our Manufacturing Locations

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.