Urethane Springs

Urethane compression springs are generally used in environments where steel wire springs are not well suited. For example, these springs are useful in applications where corrosion, vibration, and magnetism prevent the use of conventional steel springs. Urethane springs are also proven to be the safest, most efficient, and reliable compression material for punching, stamping, and drawing dies.

CAD files for stock urethane springs are available for download in our online store.

CUSTOM MANUFACTURING

Custom Urethane Springs

MW specializes in custom component manufacturing and offers many added production features, including design and tooling assistance as well as prototyping and performance testing. Contact us for more information on how we can customize the right part for your preferred application.

Urethane Springs Characteristics

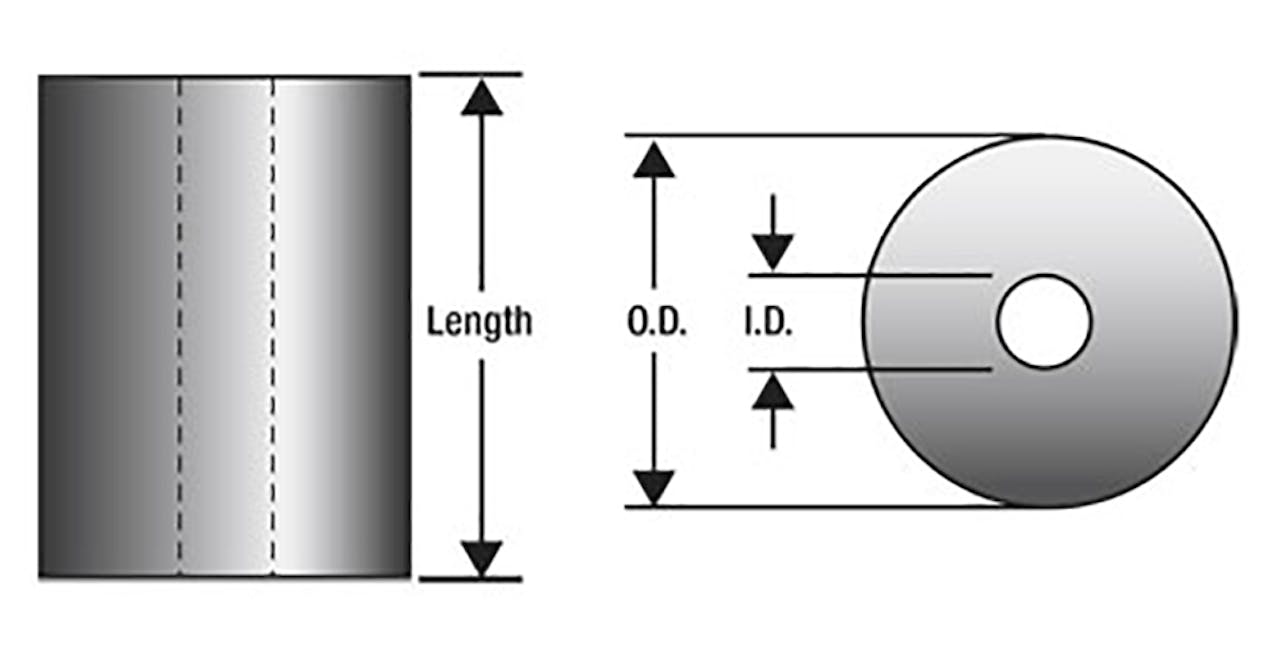

Our urethane springs are produced from a polyether-elastomer that reacts similarly to an incompressible fluid. The volume of material moved by compression is displaced laterally in the form of bulging sides. An approximation to the change in diameter of one of our standard cylindrical urethane springs can be made by increasing the diameter by the inches of compression.

Example: A 1.00″ long spring is to be deflected 15%, or .15″. The diameter will then also increase roughly by .15″. This material’s lateral expansion much be considered for many applications.

The recommended maximum free (unloaded) length is 2 1/2 times the spring’s outside diameter, although springs may be stacked with guide rods and washer-shaped spacers.

Benefits of Urethane Springs

Urethane springs offer multiple advantages over conventional springs:

- High load-carrying capability

- High dielectric strength and non-magnetic

- Protection against marring/galling

- Longer life

- Abrasion resistance

- Oil and solvent resistance

- Low noise

- Vibration damping and shock absorbance

- 100% load-bearing surface

- Bondable to mating parts

- Effectiveness between -30° F and 180° F

Urethane Spring Manufacturing

We produce stock and custom urethane springs in multiple varieties for your convenience. Additionally, our production abilities and speed are unmatched. Please review some of our capabilities for urethane springs below. Don’t see what you need? Contact us for custom quote information, and we’ll be happy to assist you.

Urethane Spring Capabilities

| Pounds to Produce 1/8" Deflection | |

|---|---|

| Conventional heavy-duty die spring | Up to 500 lbs |

| Urethane springs | Up to 2,600 lbs |

| Urethane bar stock | Up to 90,000 lbs |

| Urethane slab stock | Unlimited |

Cyclic Frequency & Deflection

Suggested maximum cyclic frequency and deflection percentage of free length

| Maximum Deflection | Cycles Per Hour | |

|---|---|---|

| Slow speeds / short runs | less than 25% | 200 |

| Intermittent | up to 25% | 700 |

| Continuous | up to 15% | 12,000 |

Our Manufacturing Locations

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.