Custom Spring Products

MW Components - Greer: Springs, manufactures a wide range of made-to-spec springs including custom variable pitch springs, custom compression springs, pigtail springs, and more. Our in-house team of engineers and manufacturing professionals even have the ability to support specialty spring configurations that you may not be able to find from other manufacturers. Contact us for a quote or get more information on our products below.

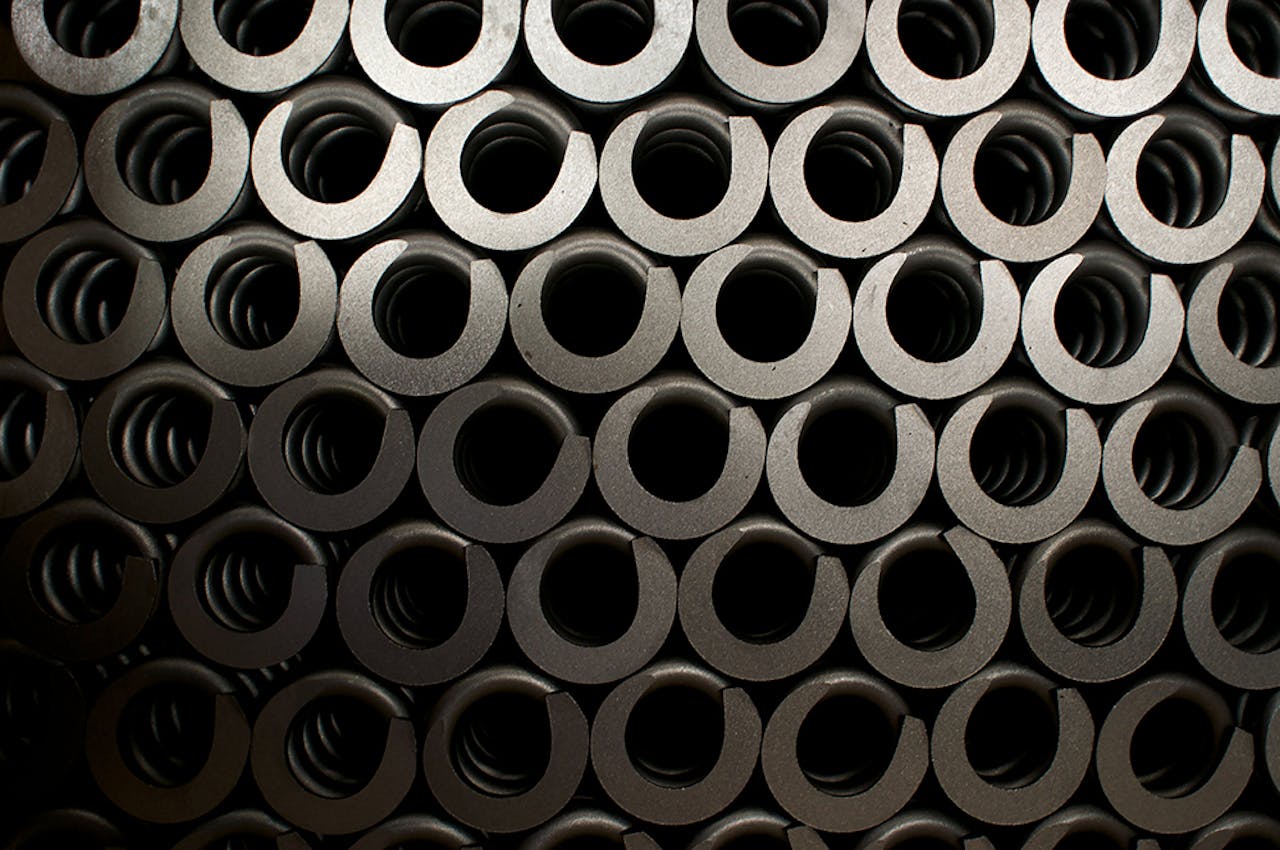

Hot Wound Springs

We manufacture hot wound springs from 0.50” (12.7mm) to 3.125” (80.00mm) bar. Our proprietary furnace technology and highly specific manufacturing processes guarantee consistency from spring to spring. This allows us to offer unparalleled metallurgical integrity and the most value for your investment.

All of our hot wound springs endure in-process inspection at each step of manufacturing to ensure product conformance, and we have computerized load-testing equipment capable of testing loads from 50 pounds (23 kilograms) to 150,000 pounds (68,000 kilograms). Request a quote for more information

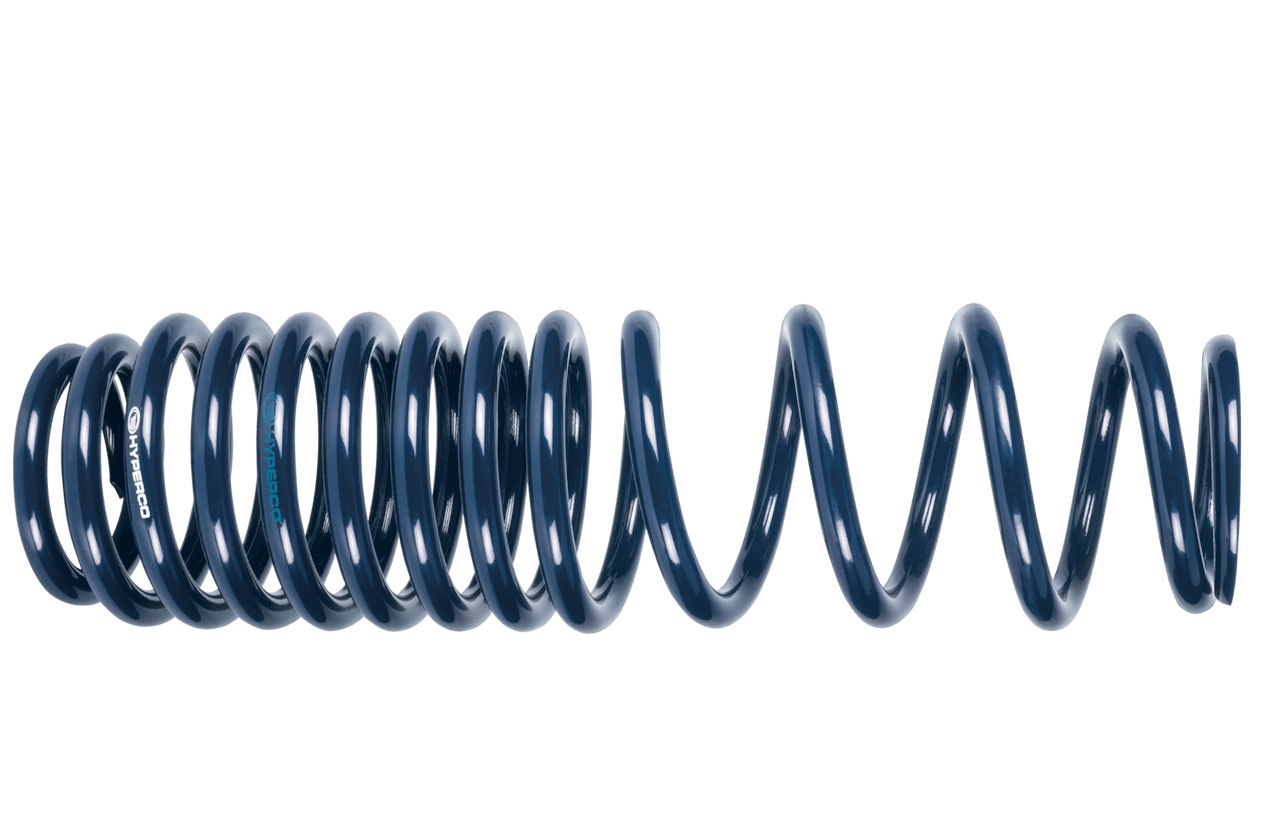

Custom Variable Rate Coil Springs

Variable rate coil springs, also known as variable pitch springs or variable pitch compression springs, are a diverse type of specialty spring. In a variable pitch compression spring, coils are unevenly spaced, often with smaller or larger spacing between coils at one or both ends of the spring. Variable pitch spring applications range, but they are frequently found in point-of-purchase retail displays. Machines and cars may also use variable pitch springs.

We manufacture custom variable force springs that deliver the highest level of performance. Contact us if you have any questions or would like pricing and lead times.

About Variable Pitch Springs

A variable pitch spring, or variable rate spring, is a mechanical spring that provides dynamic resistance as it is compressed or extended. Unlike a conventional spring, which offers a consistent resistance throughout its range of motion, a variable rate spring features a design where the stiffness or "spring rate" increases or decreases depending on how much the spring is compressed. This is achieved through a variety of design methods, such as altering the coil diameter, spacing, or wire thickness along the length of the spring.

Advantages of Variable Rate Springs

Variable rate springs offer a more adaptable and dynamic response to varying loads, making them ideal for applications where the load conditions change frequently or where a progressive response is beneficial, such as in automotive suspension systems or precision machinery.

Ddisadvantages of Variable Pitch Springs

Variable pitch springs can be more complex and costly to manufacture compared to conventional springs, due to their intricate design requirements. Additionally, their performance can be harder to predict and control, potentially leading to challenges in achieving the desired consistency in applications where precise spring behavior is crucial. To mitigate risk, it is crucial to choose an experienced variable pitch spring manufacturer who can ensure expert design and the highest quality manufacturing.

Compression Springs

Compression springs are one of the most common types of springs and are used across applications and industries. At Greer: Springs, we manufacture both hot and cold wound compression springs in a wide range of sizes. All our compression springs are custom made to your specifications. Sending us your specs or application information to request a quote.

Pigtail Springs

The term pigtail refers to a coiled spring with ends that have a smaller diameter than that of the main spring body. Often used in machinery such as conveyors, pigtail springs can be bolted to equipment and used for compression or extension. Pigtail springs can also be used in electronics and other applications.

At Greer: Springs, we manufacture custom pigtail springs for several different industries. All our pigtail springs are made to spec, contact us for details.

Cold Wound Springs

We begin with the highest quality raw materials to create cold wound springs from .250’’ (7mm) to .750 (18.75mm), offering high tensile chrome silicon for maximum travel. From there, all of our products undergo a carefully controlled manufacturing process using our state-of-the-art machinery, including CNC coilers and an in-house powder coating line.

Our automated powder coating and liquid paint lines offer a wide selection of colors and finishes; in addition, we’re able to print individual part identification codes to customer specifications. All of this is done to provide you with the most consistent and reliable cold would spring. Contact our team for more information.

Specialty Spring Configurations

In addition to standard spring types, we have the ability to prototype and produce springs with specialty configurations. Our state-of-the-art facility and expert craftsmen ensure that we can support whatever your spring needs. We work with a wide range of sizes, end types, materials, and unusual designs.

Get in touch with us to see if we can help with your unique needs.

Contact Us

Ready to get started? Contact us for a quote on custom spring manufacturing today.