In-Stock Compression Springs

Browse our inventory. We have thousands of compression springs that ship the same day. Click to filter results by material, diameter, and other parameters. Filter Results

Superior Products & Support

29

Locations in the USA

102

Engineers at Your Service

40,000

Spring Designs In-Stock

Unlimited

Custom Capabilities

The World's Largest Selection of Stock Springs, Plus Custom Build-to-Spec

With our Century Spring location, MW offers the world's largest selection of stock springs along with state-of-the-art CNC compression coiling equipment that can produce custom sizes and styles, including variable pitch springs, large compression springs, and more. We even offer spring prototyping and tooling assistance. No matter where you are in the design or production process, we have the knowledge, experience, and tools to bring your project to life.

“The springs I ordered were in stock and shipped right away at a reasonable price. Great service. Very good product.”

Find Your Spring

We have over 40,000 designs and 55 million parts in stock. If you can design it, chances are we can supply it.

Our Compression Spring Manufacturers

Custom Compression Springs

Custom Manufacturing Capabilities

Compression springs can be manufactured from a variety of materials with various finishes, wire sizes, and end types. From a large compression spring made for heavy-duty equipment to a small compression spring in a pen, choosing the right configuration involves a number of factors from application, environment, and industry. In addition to the capabilities below, we also both left and right wound springs and offer secondary processes such as grinding, shot peening, heat setting, and more. We even offer variable pitch compression springs for a variety of applications.

Material

- Carbon Steel

- Chrome Silicon

- Hastelloy®

- Inconel®

- Monel

- Music Wire

- Stainless Steels (302/304, 316, & 17-7)

- Titanium

Finishes

- Black Oxide

- Passivation

- Powder Coating & Color Coding

- Rubber

- Plating (Zinc, Nickel, Silver, Tin & Gold Electroplating)

Wire Sizes & End Types

- Cold Coiled Wire Sizes: 0.002″ – 0.75″

- Hot Wound Wire Sizes: 0.625″ – 3.00″

- Open Ends

- Closed Ends

- Closed & Ground Ends

Customer Testimonials

“Easy to use website. Great customer service.”

“The selection of springs is vast and wide. It’s all covered when trying to find the correct spring.”

“Really like that I can find the weird stuff that I need and I like how you site makes locating them easy.”

“It was very easy to check stock and pricing.”

Compression Spring Information & Resources

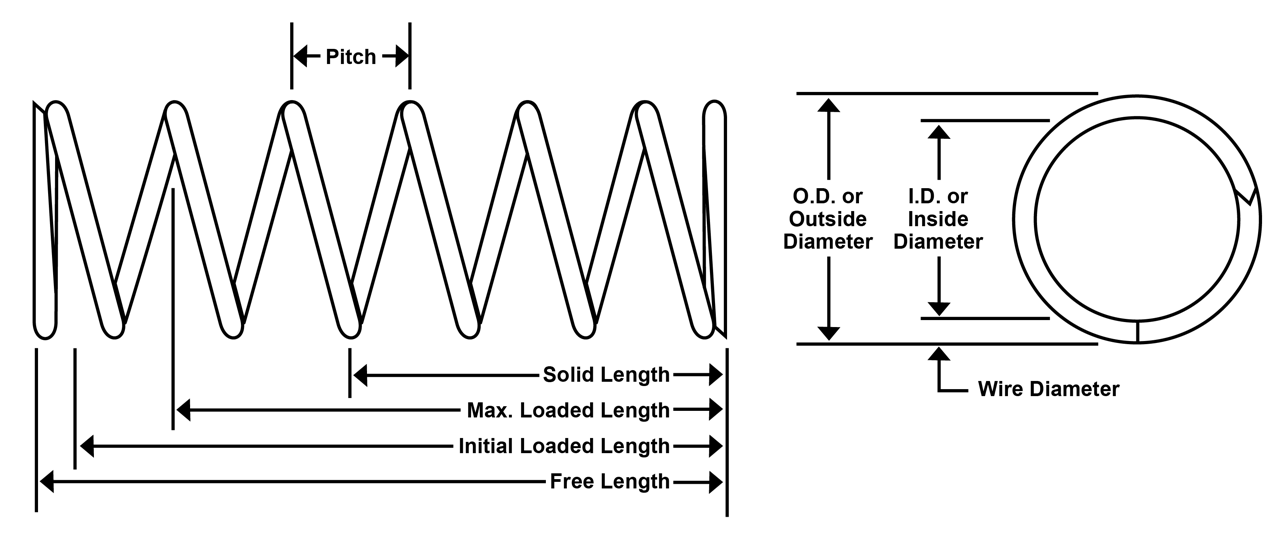

Dimensions Measurement Guide

- Hold the base of the spring in one hand, and the calipers in the other hand.

- Place the calipers on the outside of the last coil, measuring the largest dimension. This is called the Outside Diameter (O.D.).

- Place the calipers on the wire in the center of the spring. This is called the Wire or Material Size. You should also measure the wire toward one end for comparison and accuracy.

- Place the calipers on the full length of the uncompressed spring. This is called Free Length.

- Count the total coils, beginning at one end, just next to where the wire has been cut. Be sure you count all coils, including any portion of a coil. (see diagram for example)

How to Select a Compression Spring

Need more information on finding the right spring? Our engineering experts put together a full selection guide complete with design information, details on spring end types, and other characteristics you should look for in your part.

Large Wire Diameter Springs

Springs come in a wide variety of shapes and sizes. MW manufactures everything from miniature springs to large springs, including springs from large wire diameters as high as .787 inches and bar as large as 3 inches. Contact us for more information or questions on large wire diameter spring manufacturing.

Other Spring Resources

Shop In-Stock Springs

We have millions of parts in stock with over 40,000 unique spring designs that ship the same day you order. Whether you need a compression spring, extension spring, or urethane spring, we have the part you need.

Request a Custom Spring

MW Components has 20+ locations nationwide that can handle custom orders as small as one part or large production runs in the millions. We'll even provide design for manufacturability support to help reduce your costs and time to market.