Constant Force Springs

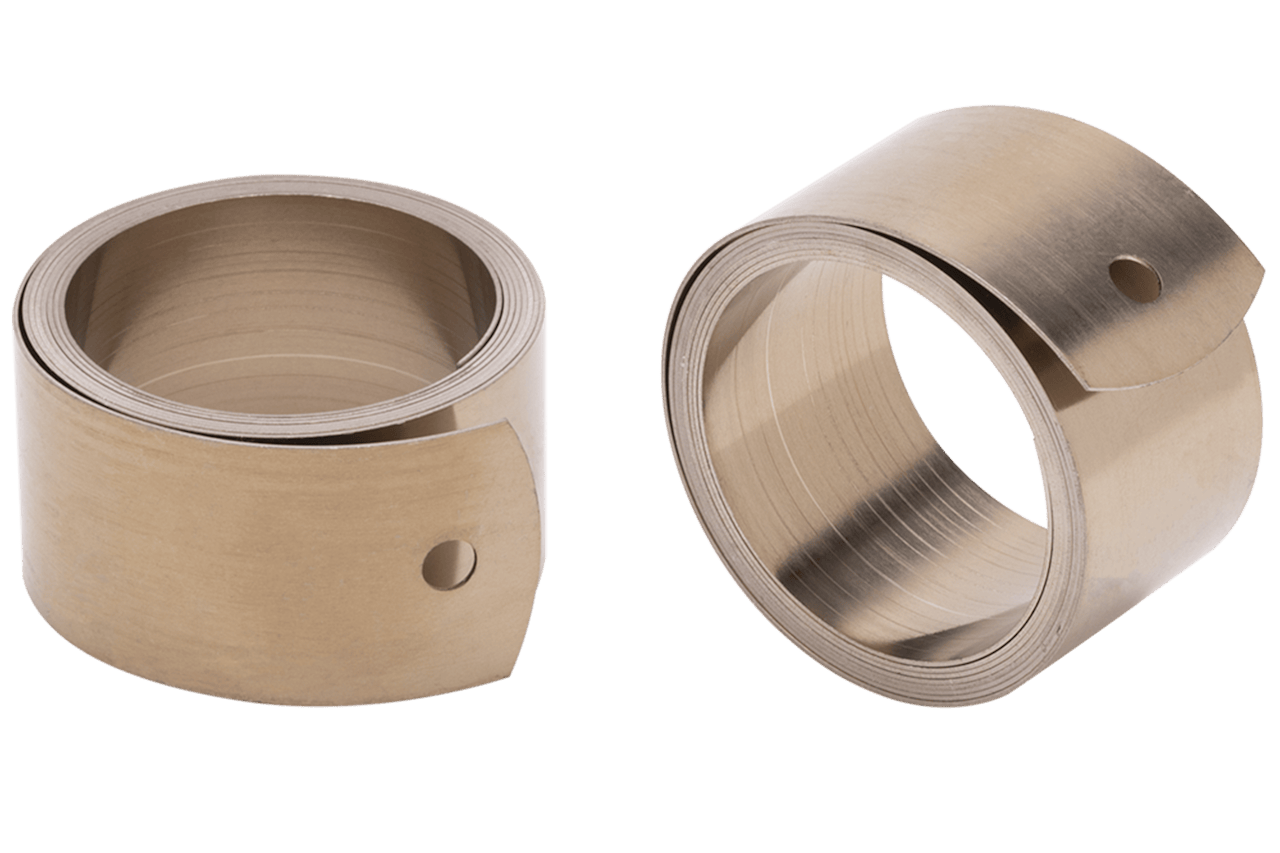

A constant force spring (also referred to as power springs or constant torque springs) is a roll of pre-stressed strip that exerts a nearly constant restraining force to resist uncoiling. The force is constant because the change in the radius of curvature is constant. This is true if the change in coil diameter due to buildup is disregarded. Long extension capabilities, constant torque, and a virtual absence of intercoil friction have led many designers to specify constant force springs in such applications as brush springs for motors, counterbalance springs for window sashes, and carriage return springs for typewriters. Constant force springs are used to drive mechanisms for timers, movie cameras, and cable retractors. It is recommended to leave at least two wraps of the spring coiled at all times during use. The cycle life is approximately 2000 cycles.

We specialize in the production of constant force springs that can be used for several applications, many times as motor or power springs, but are found most often in POP (point-of-purchase) displays and other product merchandising units. Some examples include electronic, cosmetic, pharmaceutical, and food or beverage displays.

CAD files for stock and standard constant force springs are available for download in our shop store. Or you can view our Constant & Variable Force Springs Catalog for more information.

CUSTOM MANUFACTURING

Custom Constant Force Springs

We produce several springs with standard end fittings; however, if none of these suit your needs, we are happy to custom design an end fitting for your specified application. From a few springs, to millions, we ship in any quantity and offer some of the fastest lead times in the industry.

If you would like to request a free sample kit to test our Constant Force Springs for your design or application or coordinate shipping an example of your existing trays and product for us to assist in making a recommendation, fill out our Custom Quote form.

Select request a quote to send us your specs or configure a spring.

Constant Force Springs Manufacturing

MW is a leader in the spring manufacturing industry. We provide standard and specialty processes to ensure your requested product meets your goals for quality and aesthetics. Some examples include heat treating, CNC machining, stamping, and laser etching.

Tolerances

Width tolerances for constant force springs are dictated by strip tolerances, and diameter tolerances are determined by storage and output drum tolerances. Torque tolerances are ±10% and I.D. tolerances are ±25%. Strip thickness and length should be considered reference dimensions.

Not sure where to start? Our highly trained staff of engineers and specialists are always on hand to assist with design, development, and manufacturing.

Direction of Helix (Wind)

We can configure your variable force springs in either a left or right wind configuration to suit your specific application.

Wire Types, Specs & Size For Coiling

We stock several material widths and thicknesses and can produce constant force springs in the below specifications.

Ends

We produce springs in several end configurations. Some of the most popular requested end configurations are listed; however, customizations can be accommodated as well.

Manufacturing Services

Our variable force springs can be manufactured with a selection of commonly requested services.

Quality Standards & Certifications

At MW, we pride ourselves on creating quality products that meet or exceed industry standards. Not only do our facilities perform rigorous quality assurance testing to your specified ranges, but we also maintain several key certifications to ensure that only the best products are shipped to you.

View the full list of certifications available for our products here.