FAQs

-

Have questions about our online store? Shipping options? Payment methods? Get answers to common asked questions about MW's online store.

-

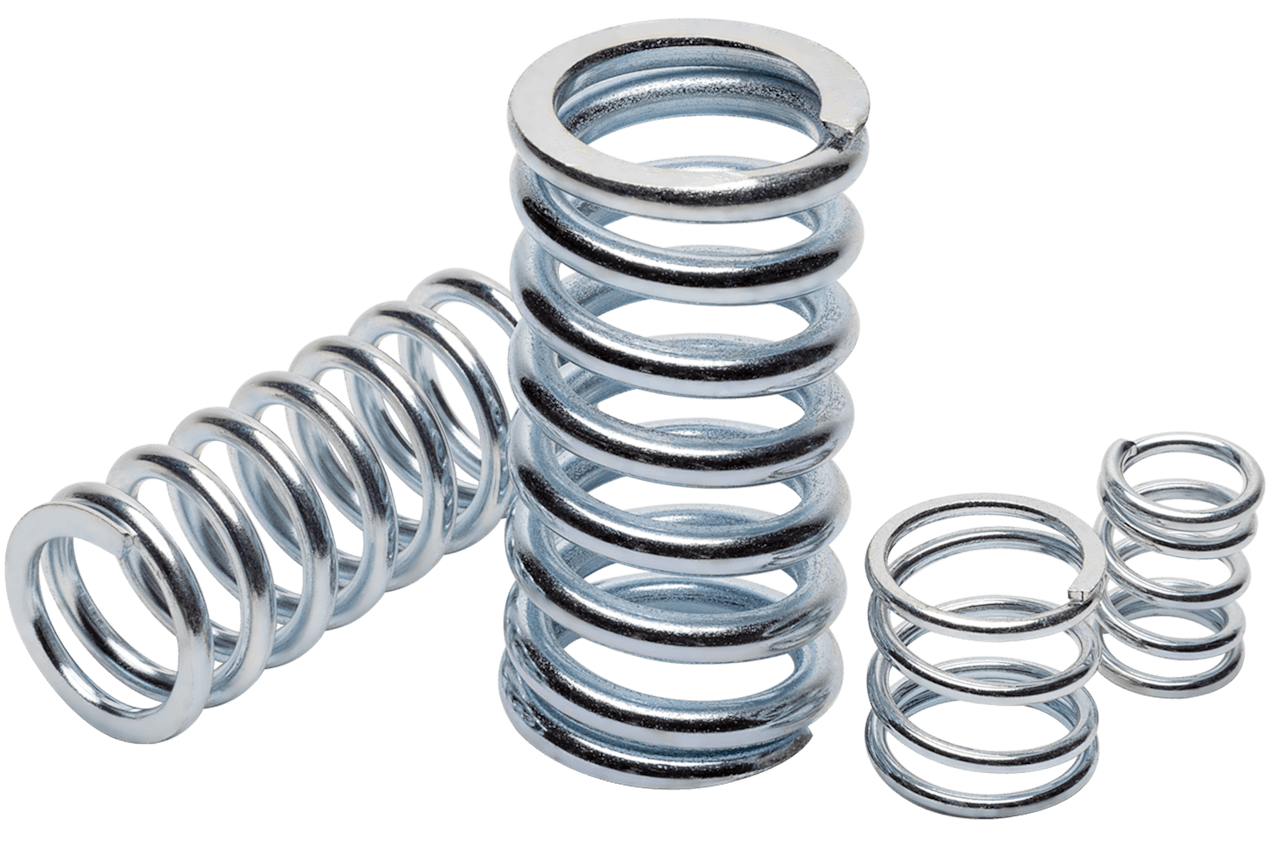

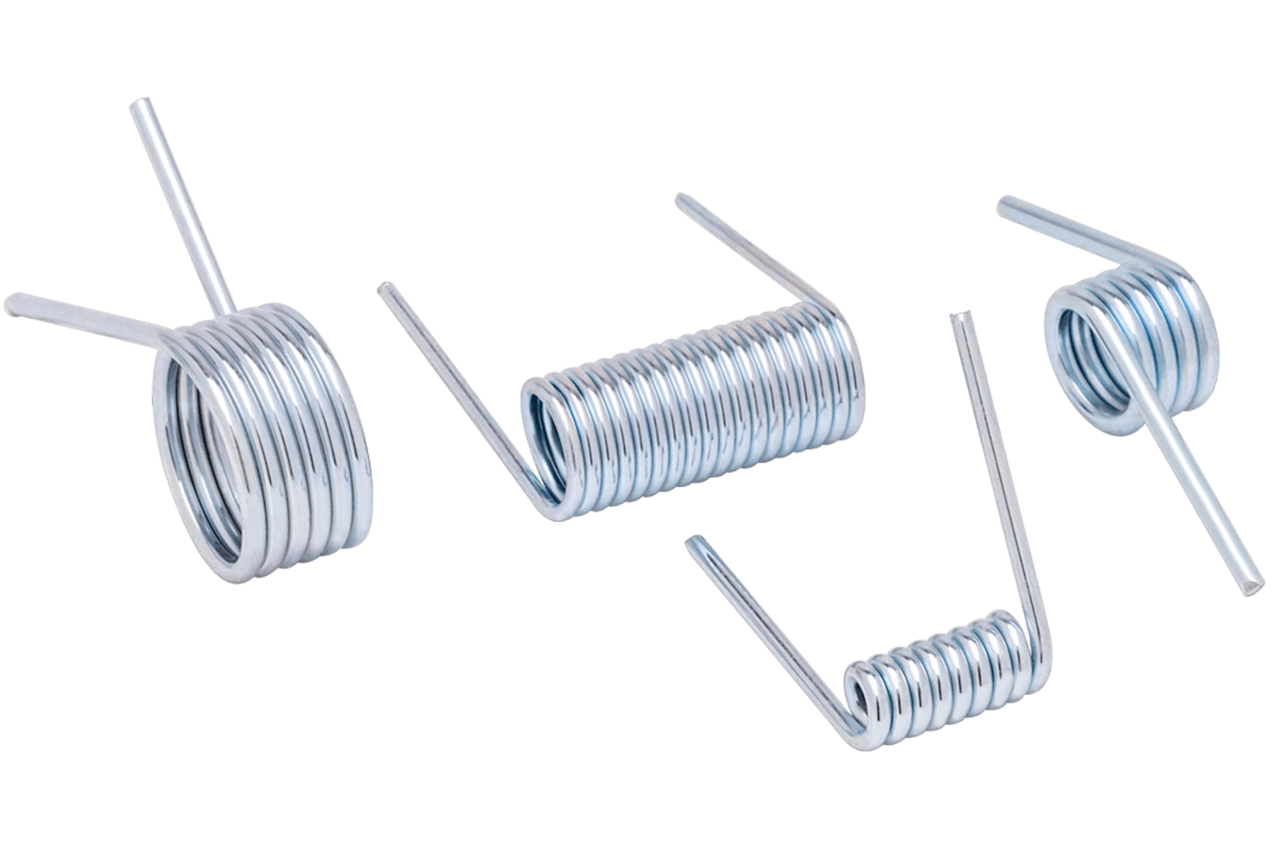

What common terms are used to describe springs? How do you calculate fatigue life? Get answers to some of the most common spring questions from the experts themselves - our engineers.

-

From the types of materials available for springs to corrosion prevention, these commonly asked questions about spring materials will help you find the right option for your needs.

-

Go more in depth with our spring design FAQs. These frequently asked questions cover everything from feature tolerancing and design stress levels to analyzing complex geometries.

-

Bellows are flexible, spring-like parts that can perform a variety of functions. Are bellows right for you? Find out with these common questions on metal bellows, their applications, and more.

-

Atherm, or athermalization, bellows assemblies are filled and sealed assemblies that translate changes in temperature into precise linear mechanical motion. Learn more about this flexible solution.

-

There are a wide variety of coupling options, including rigid and flexible options. Read our FAQs to learn more about the various options, terminology, and other details that apply to metal couplings.

-

One of our most popular question and answer sections, our fastener FAQs tackles topics ranging from corrosion to calculating shank length with countersinks. Read the full FAQ thread here.

-

How can we help? At MW Components we support our customers from start to finish. Learn more about our support services and product quality.