Products > Bellows / Couplings

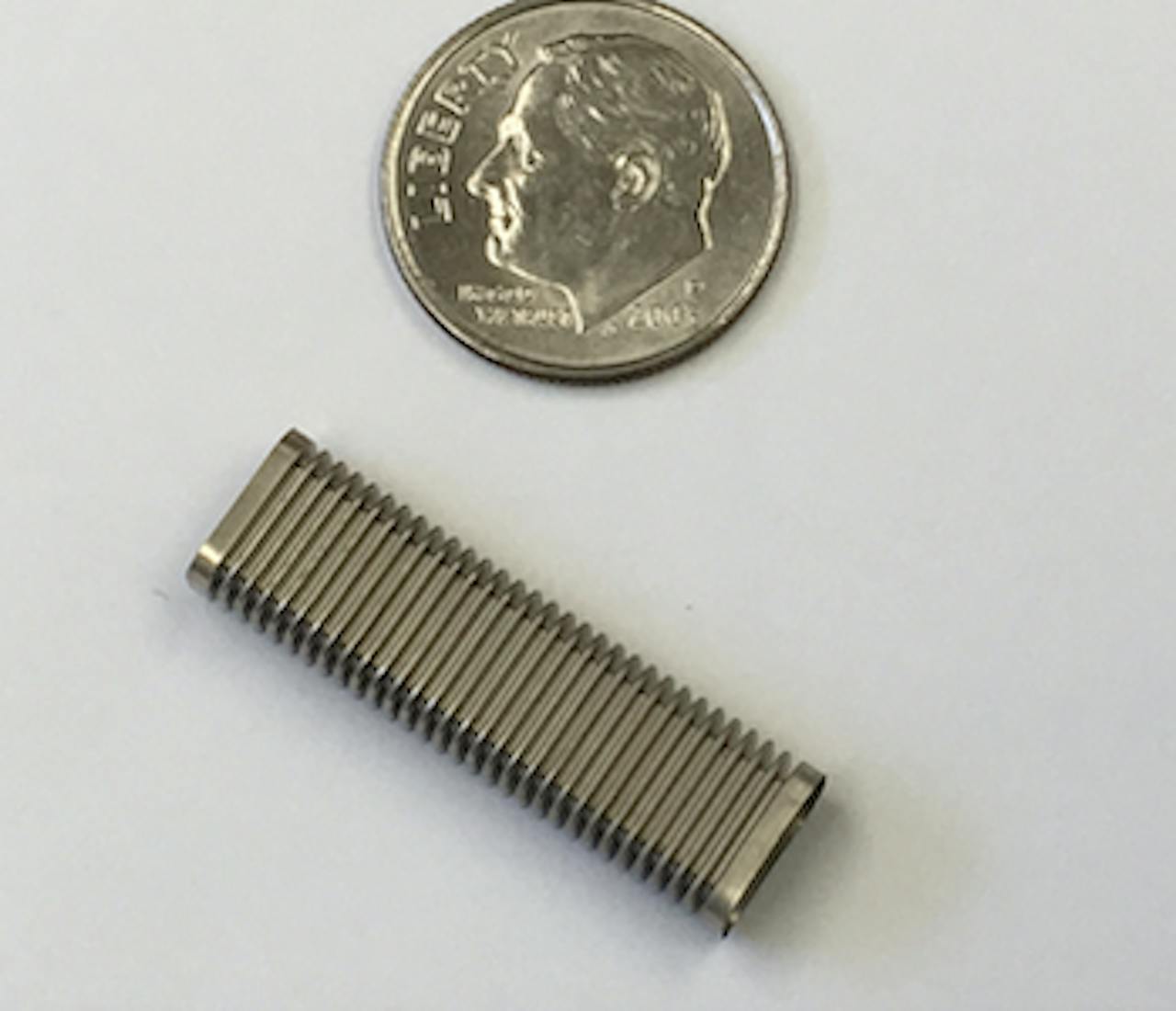

Electroformed Metal Bellows

Electroformed metal bellows, also known as electrodeposited metal bellows, are flexible, spring-like, precision-engineered components custom designed to fit into OEM parts or assemblies. Of the various types of bellows available today, only our patented manufacturing technology employs our premium alloy FlexNickel™. It offers superior performance characterization and makes our electrodeposited bellows exceptionally unique.

Our electroformed bellows are extremely rugged, yet lightweight. They are very effective, especially in mission-critical applications like aerospace and defense, where requirements demand extreme tolerances and complex geometries.

CUSTOM MANUFACTURING

Custom Electroformed Bellows

We are experts in custom bellows manufacturing and can help you design and produce a unique bellows product that meets your needs. If you have a project or application idea and you think a bellows is the right part for the job, our engineering team will work with you providing professional design assistance to make it possible.

Review 12 key design factors to consider for electroformed bellows products or request a quote for custom electroformed metal bellows from the link below.

Features of Electrodeposited Bellows

Manufactured at our Servometer location, our electrodeposited bellows deliver precise control in thousands of industrial, medical, energy, semiconductor and UHV industries as well as many others. Our electrodeposited bellows manufacturing offers:

- Thinnest wall construction (as thin as .0002 inch) for optimum sensitivity

- 25x more sensitive than hydroformed bellows

- Provide large deflections with minute forces – as small as 4 grams.

- Superb flexibility – ideal for hermetic sealing, pressure sensors and valve seals

- Can be designed to compress up to 60% of their free length

- Can be designed for an infinite cycle life expectancy with 100,000 cycles standard

- Helium leak tight to eliminate risk of contamination

- Lightweight, low mass

- No tooling charges

Our electrodeposited bellows are available in a wide range of sizes, lengths, and materials including nickel, copper, gold, and silver. Electrodeposited FlexNickel is our primary material. Electrodeposited bellows can be custom manufactured in various wall thicknesses with outer diameters ranging from 0.020 inch to 12.0 inches and convolution lengths as long as 18.0 inches. We also have 16 standard bellows sizes that come right off the shelf and are ready to test in your next OEM project. These bellows are available for quick purchase and delivery.

Non-Standard Bellows Shapes

Not all bellows are round. MW Components can produce rectangular, square, oval, and multi-faceted shapes to meet your needs. Contact us for more information.

NICKEL BELLOWS

Standard Bellows Sizes

Electrodeposited nickel bellows by Servometer Corporation are ideal for dynamic sealing applications where reliability and long life are critical requirements. For convenient and low-cost standard bellows solutions, we offer 16 standard sizes from .250 inch OD to 1.00 inch OD in various lengths and wall thicknesses. These parts are available to order in small quantities. Select the sizes you need from the chart below then contact us for more information or request a quote. Information below is for parts manufactured at our Servometer location.

Miniature Bellows Electrical Contacts

Standard Contacts

Our line of flexible miniature bellows electrical contact springs for applications where gentle contact with a delicate component or material is required. Servometer contacts have low insertion forces, low insertion losses, low decibel loss, and extremely low D.C. resistance. They have been designed to provide lifetime spring and force repeatability. Learn more here.

Interconnect Contacts

Interconnect contacts are a line of paired miniature gold plated bellows contact springs for flexible interconnection, Interconnect contacts will minimize shock and vibration in dynamic applications. Will help overcome misalignment and tolerance buildup problems in critical assemblies. The unique pairing of a contact with a convex conical tip, with a contact with a concave conical receptacle tip allows them to self-align as they connect even when they are misaligned. Learn more here.

Flexible Shaft Couplings

Our electroforming technology also allows us to produce a line of flexible shaft couplings. Our flexible shaft couplings are precision electrodeposited nickel bellows-type couplings. Made using Servometer® brand precision electrodeposited nickel bellows. Bellows couplings are indispensable for use on critical applications such as resolvers, encoders, servos, motion control devices, and computers.

The unique characteristics of the bellows couplings are:

- Very low elastic wind-up

- Zero backlash

- Low side thrust on bearings

- Zero cyclic speed variation during 360o rotation

- Low inertia

Request a Sample

Specifications

Metal Composition

Electrodeposited (electroformed) bellows are available in three types of nickel: regular, low-sulfur, and weldable. Servometer offers these options to help satisfy customers’ performance requirements.

Our standard bellows have a 0.0001″ lamination of copper between equal thicknesses of nickel. Electrodeposited bellows have about the same chemical analysis as commercial “A” nickel with the exclusion of the copper lamina. By taking this important step in the manufacturing process, we create leak-tight assemblies. The chemistry has greater overall strength and flexibility, whereas other electroforming technologies can become brittle.

Nickel Plus Cobalt: 99.8%

Interstitially deposited impurities: 0.05%

WARNING:

This product can expose you to chemicals including Nickel (metallic), which is known to the State of California to cause cancer. Read the full “Nickel Metal Material Safety Data Sheet" here. For more information go to www.P65Warnings.ca.gov.

Standard nickel bellows chemistry is bright and has a high yield strength. The main limitation is its installation method since its temperature limitation is approximately 350 degrees Fahrenheit.

Low sulfur nickel bellows have a satin finish and better corrosion resistance properties. This material can be soldered or brazed for installation into customer assemblies.

Weldable nickel bellows are the equivalent to the low sulfur nickel bellows with 0.02 maximum sulfur, but it can be welded or brazed.

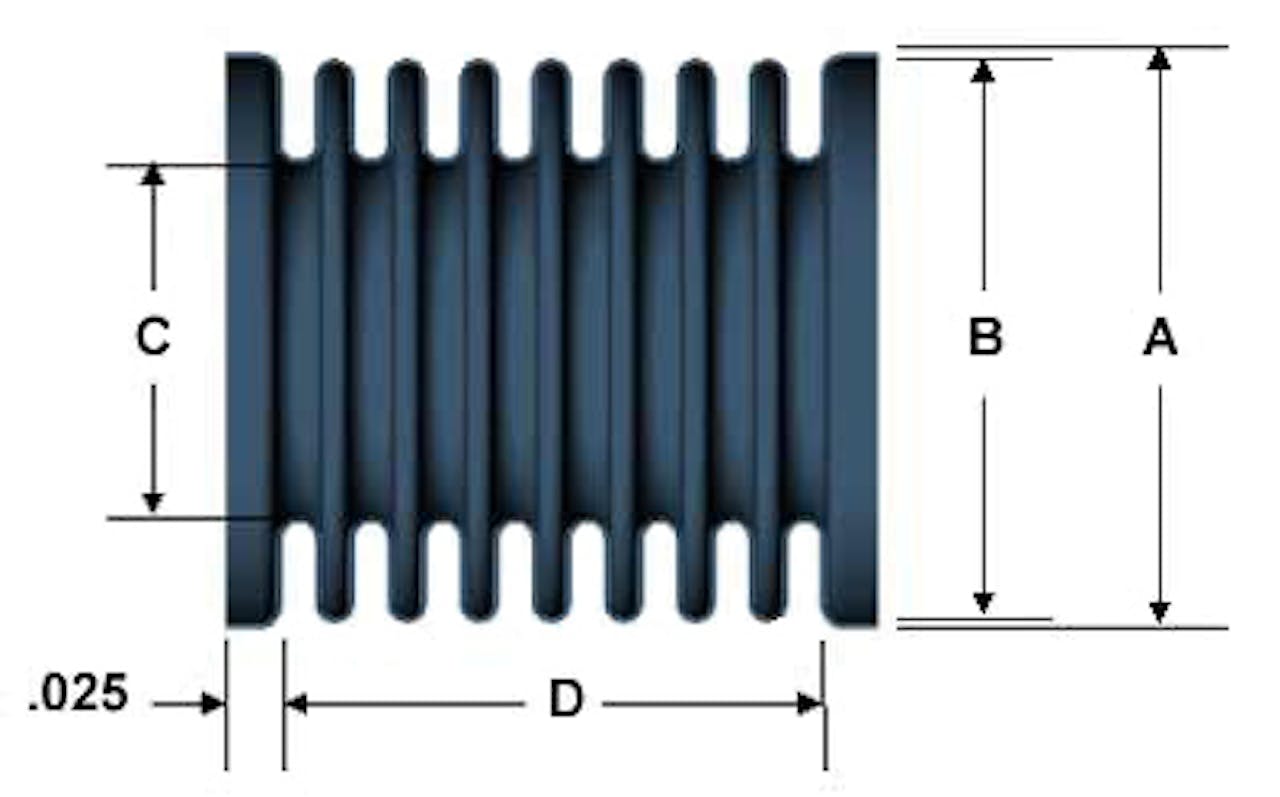

Tolerances

Specifications based on standard designs. Contact us with questions on applications that require different specifications.

Inside Diameter:

- ±0.005″ for bellows ID 0.250″ or larger

- ±0.003″ for bellows ID less than 0.250″

Outside Diameter: Tolerances vary with wall thickness and size. Diameters up to 9 inches

Length of Convolutions: ±0.010″

Length of End Trims: ±0.005″

Spring Rate: Standard is ±30%. Contact the factory with requirements if different.

Mechanical Properties

Properties encompass all nickel bellows compositions.

- Yield Strength = 110,000 PSI

- Tensile Strength = 125,000 PSI

- Elongation = 1.0%

- Hardness = 270 Vickers

- Young’s Modulus = 23,350,000

- Metal Hysteresis = within stress limits is very low

- Specific weight = 0.321 lb/in3

Leak Tightness

Bellows are 100% tested via mass spectrometer to 1×10-6 cc/sec of helium standard, leak rates of 1×10-9 cc/sec of helium can be provided on a custom basis. For applications requiring testing tighter tolerances, contact the factory.

Corrosion Resistance

Nickel is more resistant to corrosion than brass or bronze, but not as much as stainless steel. Electroformed bellows will not oxidize in the air or be affected by alkaline liquids. Contact us for applications requiring a metal bellows assembly with more corrosion-resistant properties. MW Components' edge-welded metal bellows may need your needs.

Magnetic Properties

Our electrodeposited nickel is ferromagnetic. Electrodeposited copper is non-magnetic and can be utilized for special applications.

Surface Finishes

Gold Plate – 24 carats – ASTM-B-488 is supplied either to enable soft soldering without flux or to provide a surface for microwave fields.

Silver Plate – commonly applied to bellows in microwave guides.

Parylene coating can assist in protection from certain corrosive atmospheres and media.

Applications

Electroformed Bellows Applications

MW Components manufactures standard and custom electroformed bellows for various applications. Some of the more common applications for this manufacturing process include the below.

Custom Electroformed Bellows from Our Servometer Location

UNIQUE SOLUTIONS TO CHALLENGING PROBLEMS

Custom Metal Bellows Design & Manufacturing

Servometer specializes in creating one-of-a-kind solutions to some of the most difficult problems in mission-critical applications. Servometer miniature metal bellows can be used for metallic hermetic seals, volume compensators, pressure and temperature sensors, flexible connectors, and countless other applications where quality, dependability, reliability, and long life are critical requirements. Our team of engineering and manufacturing experts will work with you to design and produce the most effective metal bellows for your needs. From a single prototype to the production of thousands of parts, we’ll ensure the entire process goes smoothly and you get the components you need.