Military Antenna Springs

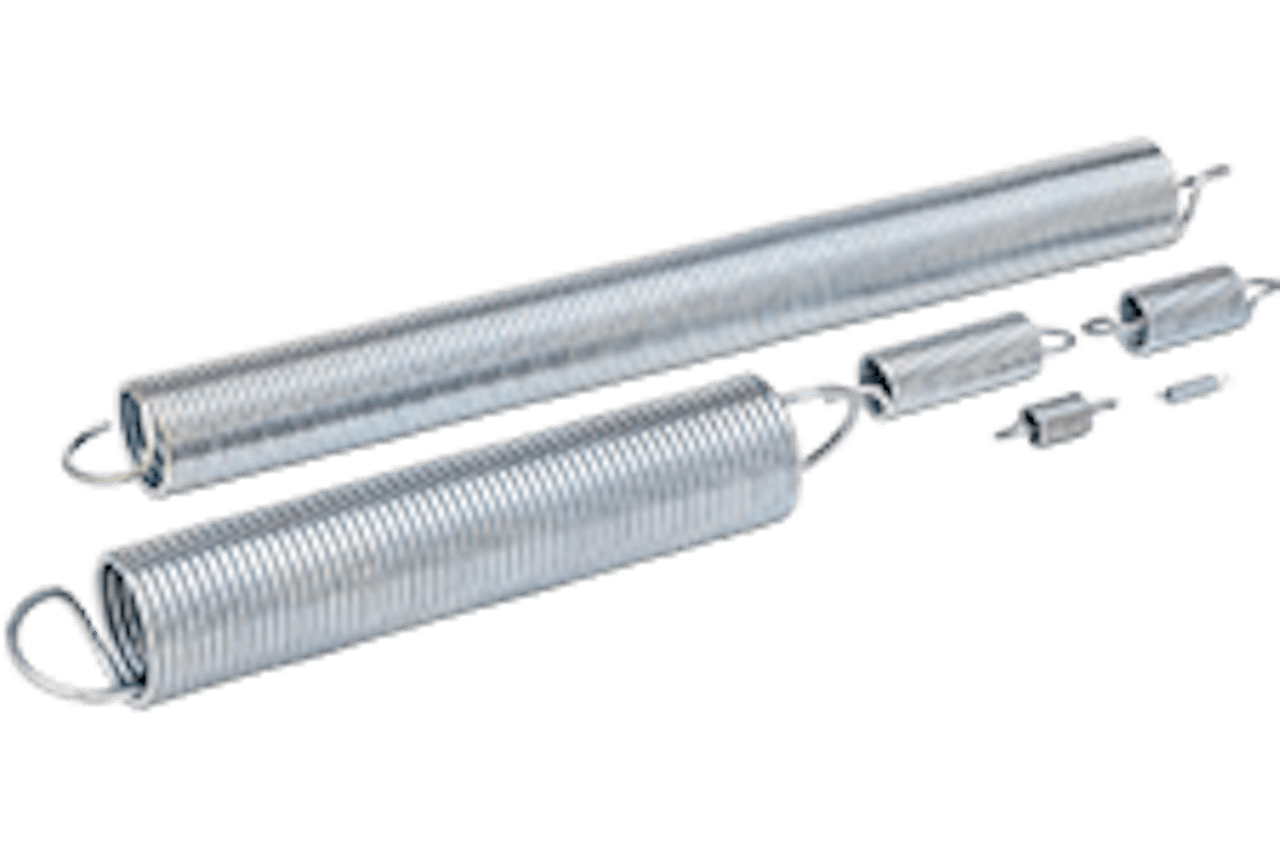

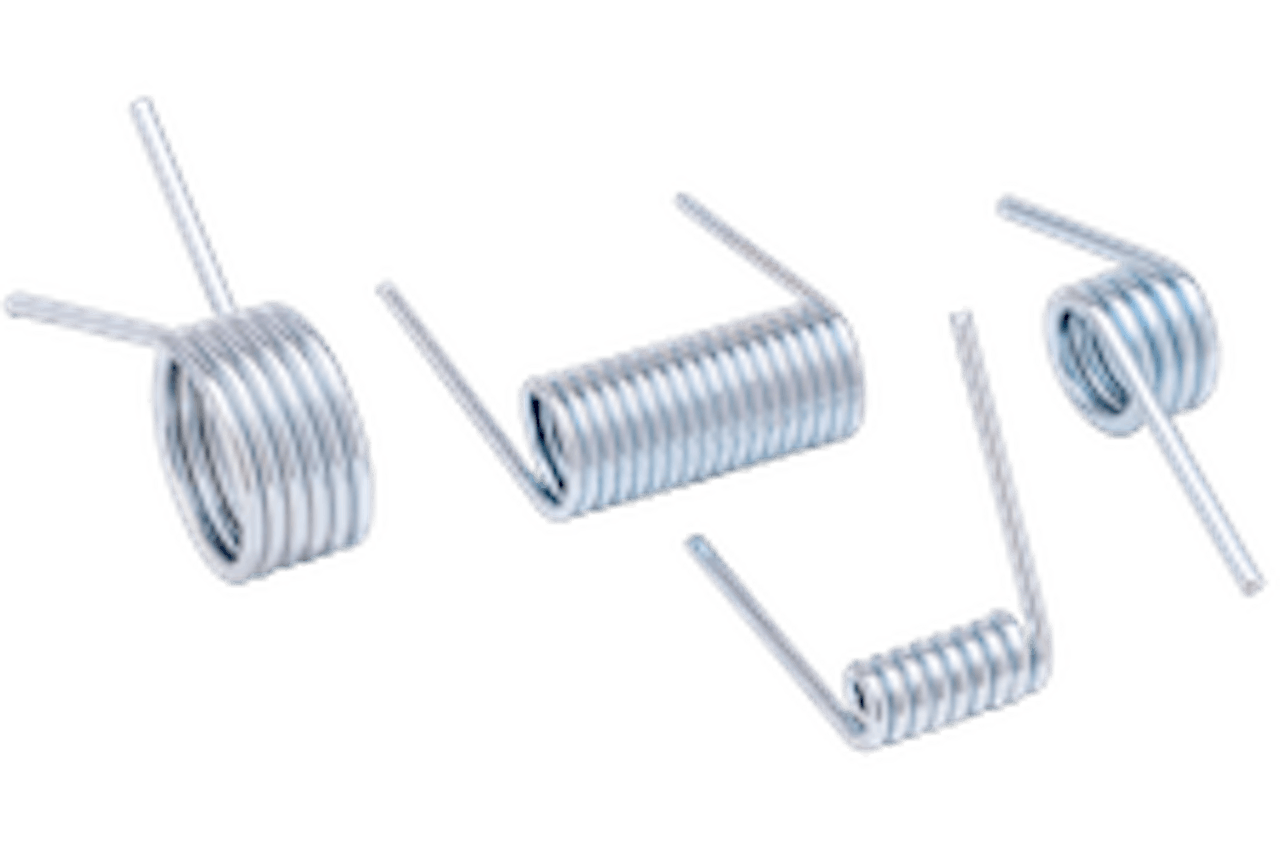

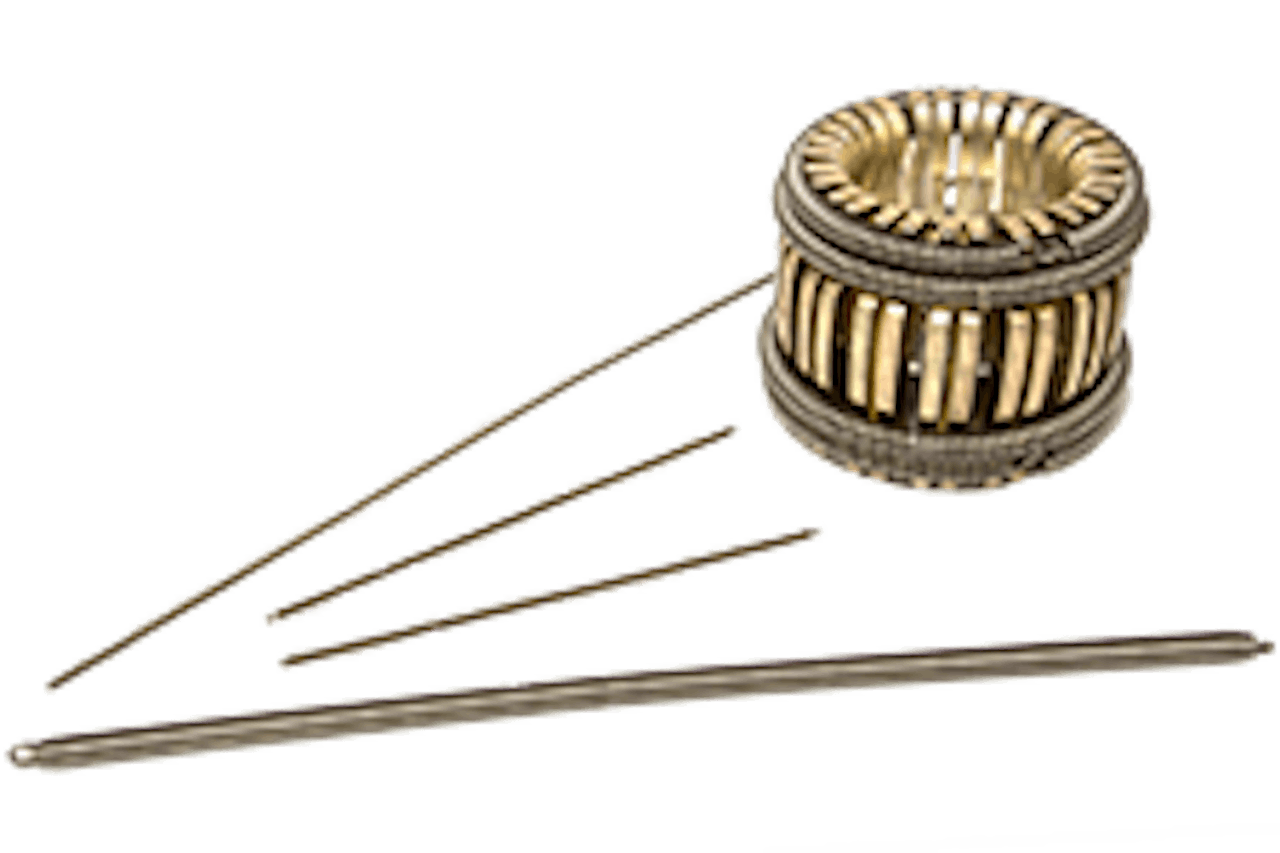

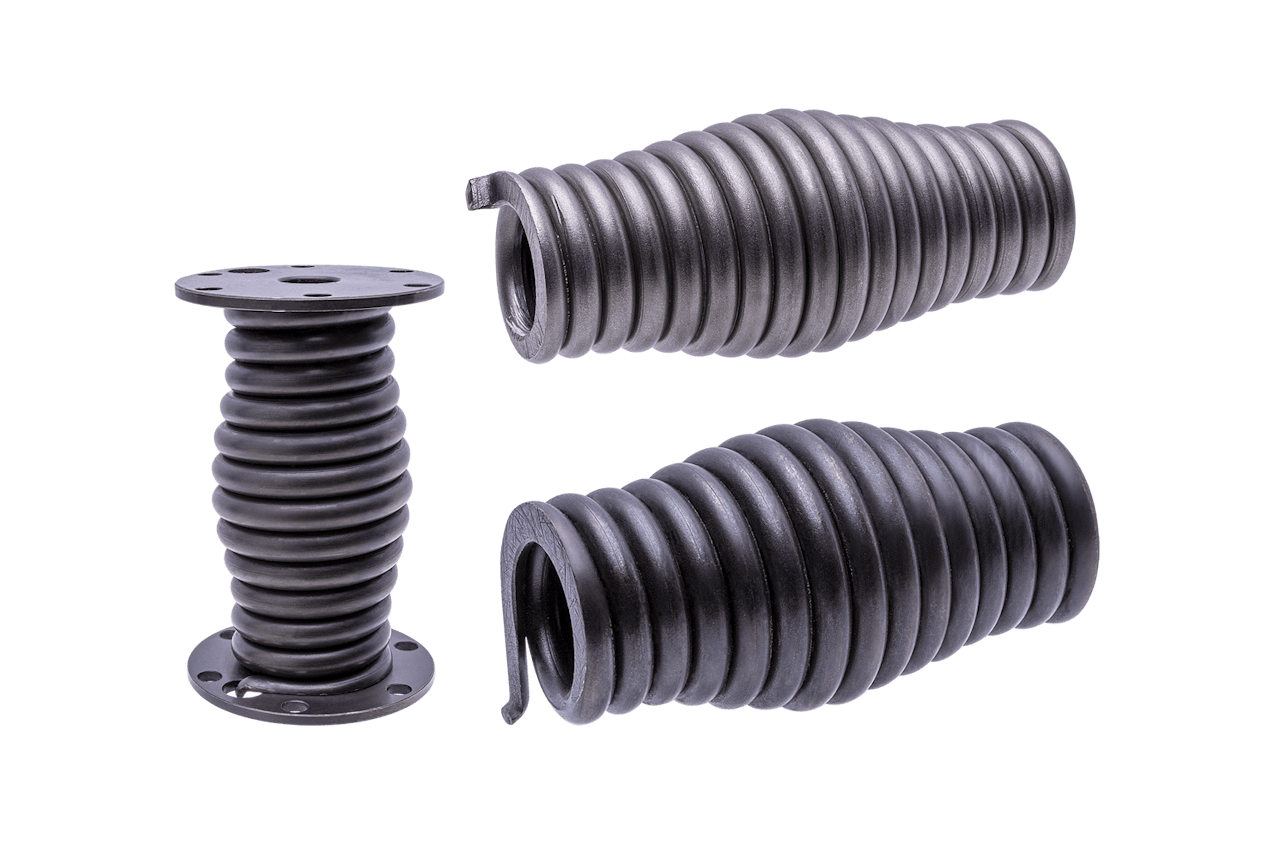

Antenna springs also referred to as whip antenna springs, are used at the base of a vehicle antenna to ensure stability and support of the antenna mechanism. MW Components produces a variety of antenna springs, many of which are barrel springs, spanning multiple sizes and finish options. We work with you to determine the correct spring for your application to ensure the best fit.

Antenna springs are formed with metal tangs on the end which allows for locking into the metal base of a vehicle. Improper locking due to antenna spring malformation can lead to antenna breakage. To ensure the highest quality antenna springs with the longest possible cycle life, we perform rigorous in-house testing for torque, tension, and whip. MW Components’ antenna springs are developed to withstand harsh environmental conditions, particularly military applications.

CUSTOM MILITARY SPRING MANUFACTURING

Custom Military Antenna Springs

The majority of the antenna springs we produce are made with stainless steel and finished with a black oxide coating which provides light reflection, rust prevention, and adds durability to the part. However, we are a custom spring manufacturer, meaning we work with your teams to develop the correct part for your specific application. This could include any number of finishes, certifications, etc.

We even offer design and engineering assistance from industry experts at no cost to you. We also have a vast repository of wire thicknesses and machining capabilities across multiple manufacturing facilities, ensuring that whatever you require for your custom antenna springs and assemblies, we can produce them.

Military Antenna Spring Manufacturing

Our antenna springs are produced to withstand harsh environments and are built to last due to our propriety production process which includes advanced CNC machining. In addition to state-of-the-art manufacturing, all antenna springs undergo rigorous testing for durability and cycle life, including a whip test, bend rate, flex test, and initial tension test. This ensures only the highest quality parts are used in your assemblies. We also offer a variety of optional certifications to comply with industry standards and further ensure the performance of your parts.

We are a custom spring manufacturer and a custom component manufacturer with multiple facilities, giving you access to a wide variety of size ranges, materials, finishes, and customization options. Since our production capabilities extend beyond springs, we are able to perform end-to-end production on spring assemblies, ensuring that each and every component within those assemblies functions perfectly as intended.

Not sure where to start? Our in-house design and engineering team with decades of component production and industry knowledge is at your disposal. Contact us for a custom quote to get started.

Antenna Spring Bases

As a custom antenna spring and spring assembly manufacturer, we can make nearly any spring base upon request. Please contact us with your needs and we'll work with you to come up with the optimal design, materials, and quote. Below are a few of our commonly requested materials, finishes, and quality certifications for spring bases.

Finishes

Our antenna springs can be manufactured with a selection of finishes and processes. Finishing processes may include grinding, shot peening, and heat setting. Common spring finishes include the below.

Certifications & Compliance

We offer a variety of certifications and compliance, including for military applications. Below are some of the most commonly requested. Any of these can be applied to our custom parts. For a full list of all MW Components certifications and compliance documents across all industries, visit our compliance page.

Other Coiled Spring Products

Our Manufacturing Locations

Request a Quote

Ready to start your project? Request a quote today. We'll get in touch with details about design, manufacturing, pricing, and lead time for your project.