Inconel

High-Temperature & Corrosion-Resistant Nickel Alloy

Inconel is a group of alloys containing mostly nickel with chromium and is resistant to corrosion and high temperatures. It was developed in the mid-1900s for nuclear reactor applications.

Grades / Attributes

Inconel X-750 is most common for spring and wire because this grade offers the best combination of high temperature, corrosion resistance, and availability. Inconel 718 and 600 are also used for coiled springs as well as Belleville washers.

Spring Applications

Valves that are used with high temperature fluid or steam (nuclear reactors for submarines and aircraft carriers). An example is the springs used in vacuum furnaces for semiconductor manufacturing. It is also National Association of Corrosion Engineers (NACE) approved for “down hole” gas exposure. Other uses include lower-tier tools, which will not be subjected to severe service or have a short lifespan, where term corrosion exposure is not an issue.

Material Benefits

Alternative material for MP35N and Elgiloy, at less than half the cost. However, it is not as resistant to certain chemicals as compared to MP35N and Elgiloy.

Considerations

Moderate resistance to chlorides, saltwater and acids. If your application requires more strength and corrosion resistance, upgrade to MP35N or Elgiloy.

Other Inconel Products

In addition to springs, inconel is often used for other metal components, including inconel bellows.

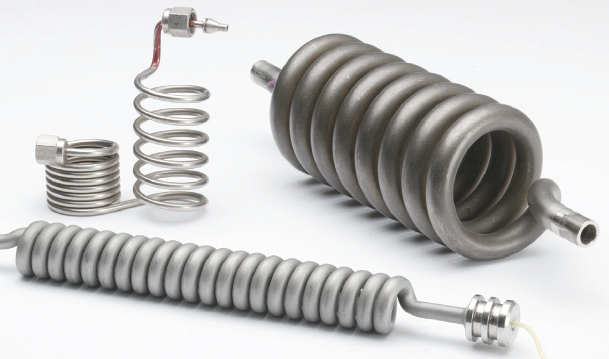

Custom Inconel Springs

MW Components manufactures custom Inconel springs to meet your mission-critical application needs. With in-house tool and die manufacturing along with coiling, forming, and testing, we can manufacture Inconel springs including:

- Inconel compression springs

- Custom 718 springs

- Inconel X750 springs

- Flat, bow, and drag springs

- Garter springs

Request a quote or contact us to get in touch with an engineering or manufacturing expert. Our engineers are experts in solving unique problems and finding solutions to challenging use cases, such as those with severe-service requirements. We’ll help you get, or design, the part you need for your project.

Contact Us

Need more information on stock or custom inconel springs? Contact us.