Products > Springs > Disc Springs / Washers

Flange Disc Springs

Flange disc springs, or flange washers, are different from other Belleville washers and disc spring variations due to their unique shape, which includes a thin outside edge. In addition to structural differences, they tend to withstand extreme heat and pressure better than their alternatives.

Flange disc springs are precision-machined on all surfaces, with well-rounded edges. They can be used as a single disc spring or stacked on each end of a bolt, depending on estimated bolt elongation.

CAD files for stock and standard flange disc springs are available in our online store.

CUSTOM MANUFACTURING

Custom Flange Disc Springs

All our disc springs are subject to exacting manufacturing and quality control standards. All discs are preset so that they will not significantly relax under load over time. MW also offers pre-stressed disc springs specifically sized for use with bolts.

Send us your specs or configure a custom component.

Flange Disc Springs Manufacturing

Flange washers are manufactured to include a small outside diameter for a pairing bolt size. They are often manufactured using carbon steel or stainless steel; however, they can also be produced from a variety of temperature and corrosion-resistant materials.

Characteristics

There are many characteristics of flange disc springs that make them attractive for various industries and uses. Our disc springs are commonly found in high temperature or extreme pressure situations, pipe flanges, bolted joints, heavy and light bolting, dynamic functions, and bearing preloaded washer applications.

Tolerances

OD: + .000 / - 1.5% x OD (Designed for standard flange spot face diameter

ID: - .000 / + 1.5% ID

Thickness: ± 5% x nominal thickness shown

OH: is a reference and used to control the needed load

Load: ± 20% of nominal shown

HRC: 4-45

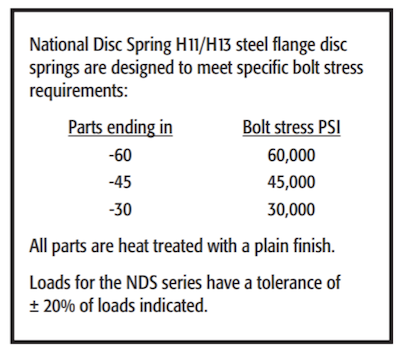

Bolt Stress Requirements

Flange Disc Springs Configurations

Flange Disc Springs (NDS)

Flange disc springs (NDS) perform well in extreme conditions due to some key advantages, which are: maintaining bolt tension and gasket pressure around the flange and being able to automatically adjust for thermal variation, vibration, and mechanical shock stress.

Flange Disc Springs (FL / MFL)

Flange Disc Springs (FL / MFL) have elastic mechanical elements which make them perfect for pipe flange applications. Reactive power keeps the bolt joint tight under all conditions.