Belleville Washers

Belleville washer or Belleville disc springs have a conical shape that generates a high force in a concise spring length and minimal movement when compressed. Belleville washers' advantages include high load capacity within a small space, shock absorption, dampening functionality, high tension maintained in bolted applications, and load characteristics that can be modified by stacking.

CAD files for stock Belleville washers are available for download in our online store.

CUSTOM MANUFACTURING

Custom Belleville Washers

All our disc springs are subject to exacting manufacturing and quality control standards. All discs are preset so that they will not significantly relax under load over time. MW also offers pre-stressed disc springs specifically sized for use with bolts.

Belleville Washer Manufacturing & Configurations

Disc springs are used in several industries and applications. They are ideal in situations where tension is lost due to thermal expansion or contraction, compression set, or when wear of parts occurs. Belleville washers and disc springs are unique because they exert a constant uniform pressure and are perfect for multiple assemblies used for drilling, stabilization, and shock absorption.

Depending on your application's needs, you can consider using Belleville washers singly or in stacks. Your configuration will depend on your desired load and travel. In most cases, Belleville washers perform best in high load and short-travel conditions, such as those used in confined spaces. If stacking disc springs, you can use parallel or series stacking configurations.

-

Parallel Stack

Parallel StackParallel stacking allows you to maintain a maximum deflection of a single Belleville washer, while gaining load capacity. For instance, if you stack three Belleville washers in a parallel configuration, you have a maximum deflection of one Belleville washer, but gain three times the load capacity.

-

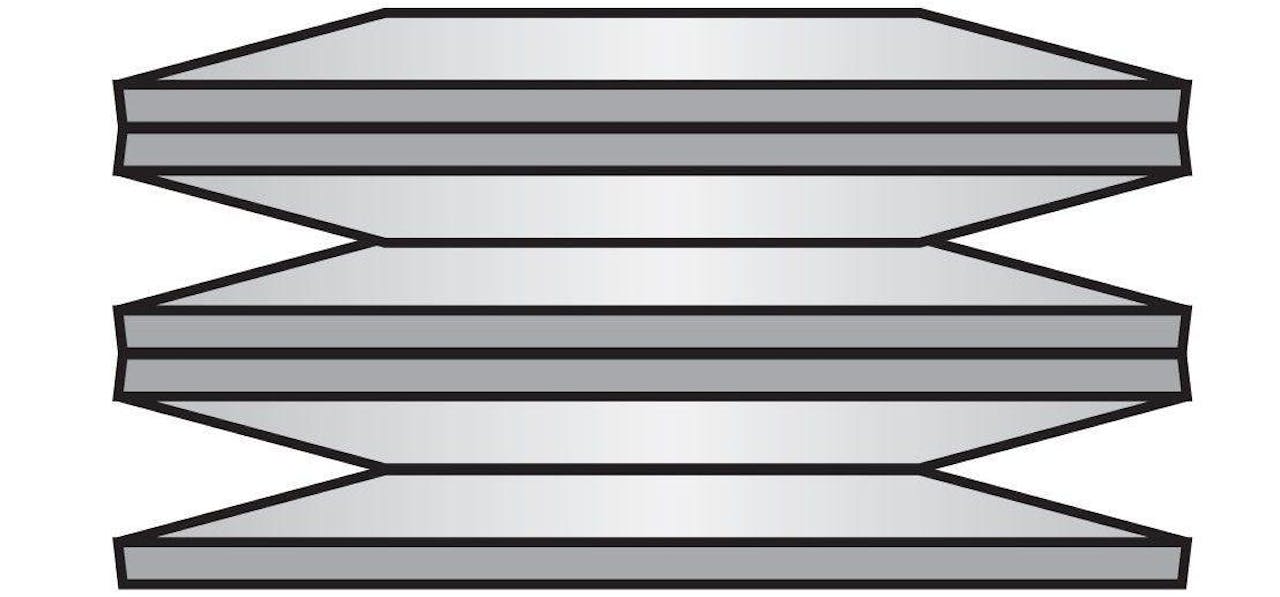

Series Stack

Series StackSeries stacking retains the load of a single Belleville washer, but increases the deflection. Three Belleville washers stacked in series will have three times the deflection of one disk, with no change in load.

-

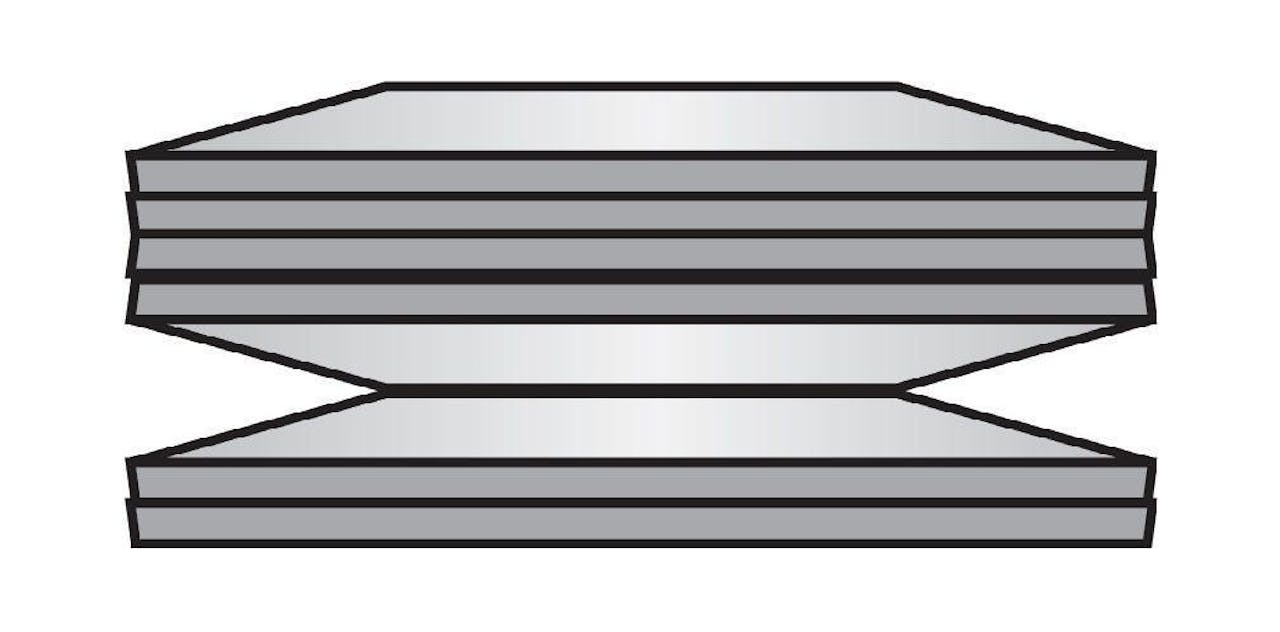

Mixed Stacking

Mixed StackingMixed stacking incorporates both parallel and series configurations. Depending on the combination, you can create nearly any load and deflection trend.

Materials

MW stocks standard and specialty materials of all types. Below are some commonly requested materials used to manufacture Belleville washers.

Other Belleville Washer and Disc Spring Products

Our Manufacturing Locations

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.