Capital Spring

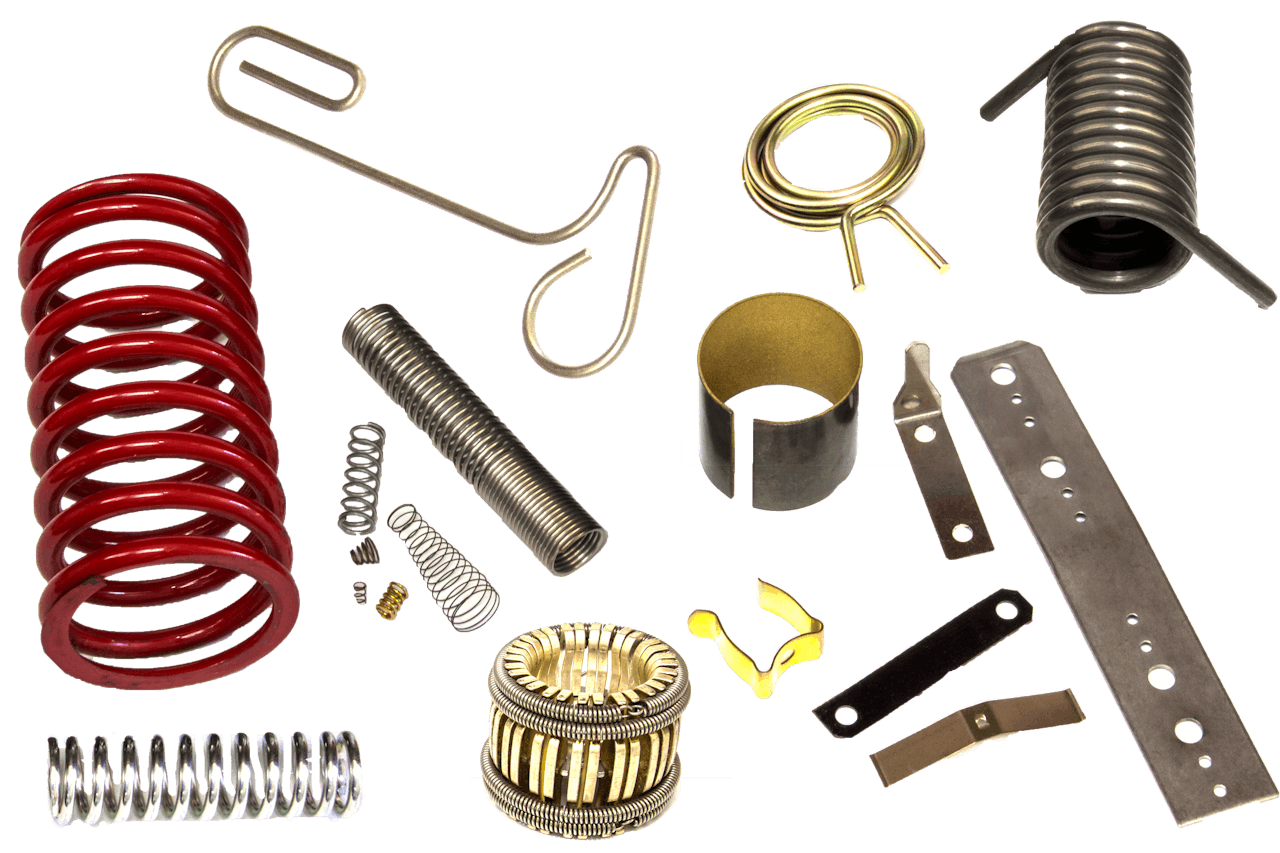

Metal Springs, Wire Forms, and Stampings

Capital Spring has been manufacturing high-quality extension springs, torsion springs, compression springs, wire forms, fourslide parts and small metal stampings since 1945. Our products are made to the highest standards and we are ISO9001, AS9100D, ITAR, and JCP compliant.

To ensure the most efficient prototyping and production for our clients, we consistently evaluates and invests in the latest technology in order to improve throughput, increase repeatability, and reduce costs. Our team of engineers and manufacturing experts can help with everything from design questions to timelines and cost. Partner with us to get the products you need, when you need them. Contact us for a quote today.

Products

-

We offer compression springs from wire diameters of .007” to .625”.

-

Our extension springs are available from wire diameters of .008” to .625”.

-

We offer single body torsion springs from wire diameters of .008” to .625” and double body torsion springs from wire diameters of .008” to .236”.

-

Our garter springs are most commonly available from carbon steel or stainless steel round wire.

-

Capital offers a wide variety of wire forms from different materials and wire sizes.

-

We manufacture fourslide products and small metal stampings with varying wire diameters and thicknesses.

Featured Industry: Aerospace & Defense

Titanium Springs & Components

Capital Spring has been AS9100 certified since 2016 and now has nearly a decade of experience producing the highest quality aerospace springs and military components. We are one of the few suppliers with in-house experts who can quote and produce titanium springs - a must for the military and aviation sectors. Contact us with questions or to request a quote today.

Materials

- A286

- Beryllium Copper

- Carbon

- Elgiloy

- Hastelloy

- High Temperature Alloys

- Inconel

- Monel

- Stainless Steel (all grades)

- Steel

- Titanium