Products > Precision Components

Wire Forms

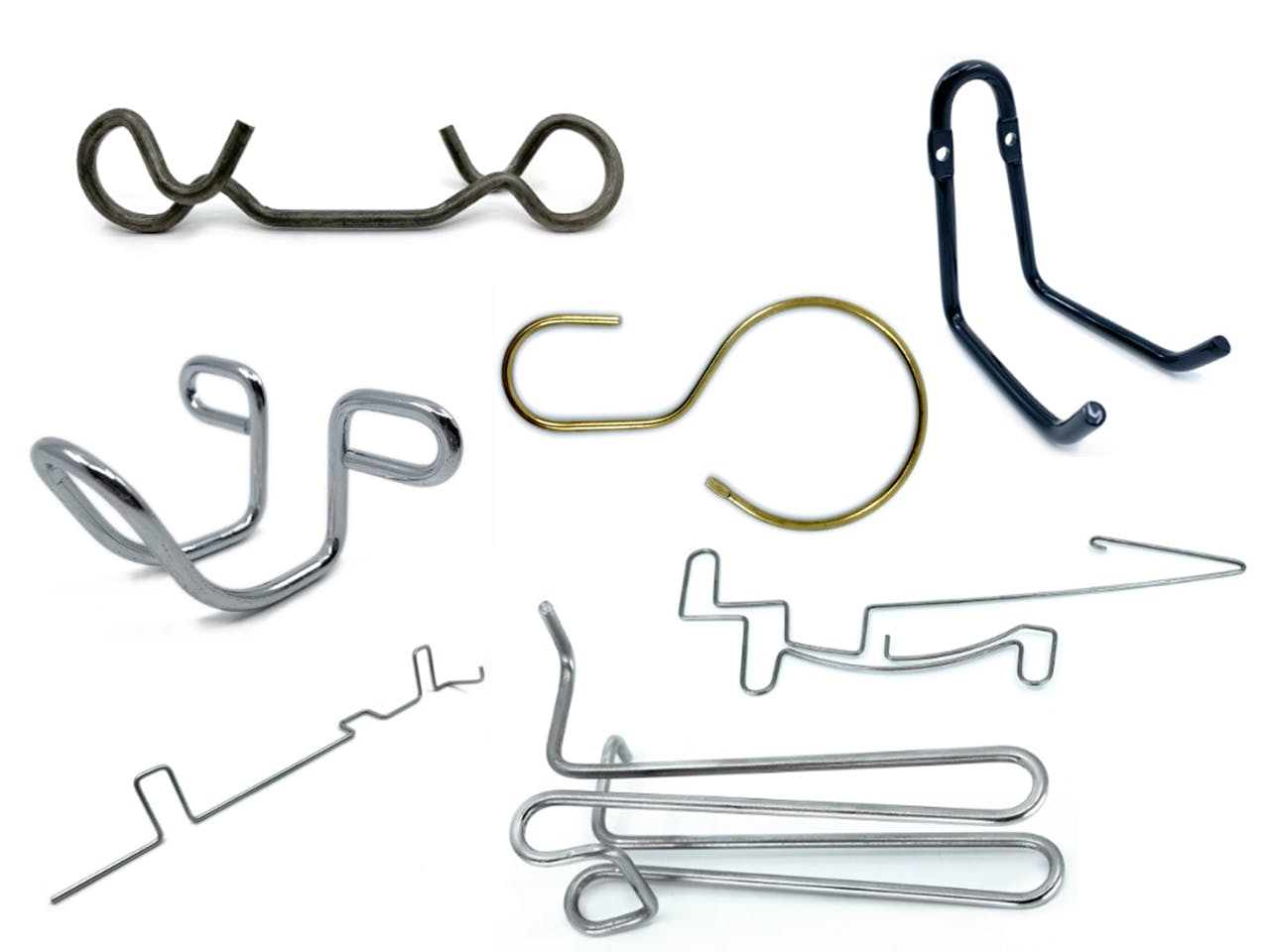

Wire forms are have endless configuration options, making them frequent components used in both industrial and general use consumer products. They are made from shaped wire and can include parts used in lightbulb filaments, musical instruments, clocks, medical trays, pins, pegs, and rivets.

We offer stock wire form fasteners such as cotter pins and hitch pins, as well as custom wire forms. Since there are nearly unlimited designs for custom wire forms we'll work with you to determine the best material, size and manufacturing process to create a product that suits your needs.

Explore Our Wire Forms and Manufacturing Capabilities

CUSTOM WIRE FORM MANUFACTURER

Custom Wire Forms

MW produces custom wire forms in a wide variety of wire sizes from .006″ through 1.00″ and lengths up to 12'. A few of our products include different styles of pins like cotter pins, hitch pins, and lock pins, as well as S hooks, D rings, figure 8 hooks, grip clips, hog rings, and others.

In addition to our large variety of configurations and sizes, many material options are available depending on your design and application – including high-strength and annealed spring materials. We offer prototyping and coatings or surface treatments including, plating, passivation, cleaning, polishing, and heat treatments, in addition to custom packaging and JIT (Just In Time) delivery as needed. With ISO9001 certification and industry expertise in aerospace, defense, agriculture, medical, commercial, and others, we have the knowledge necessary to ensure optimum performance for your precision wire forms.

Popular Wire Forms & Wire Fasteners

-

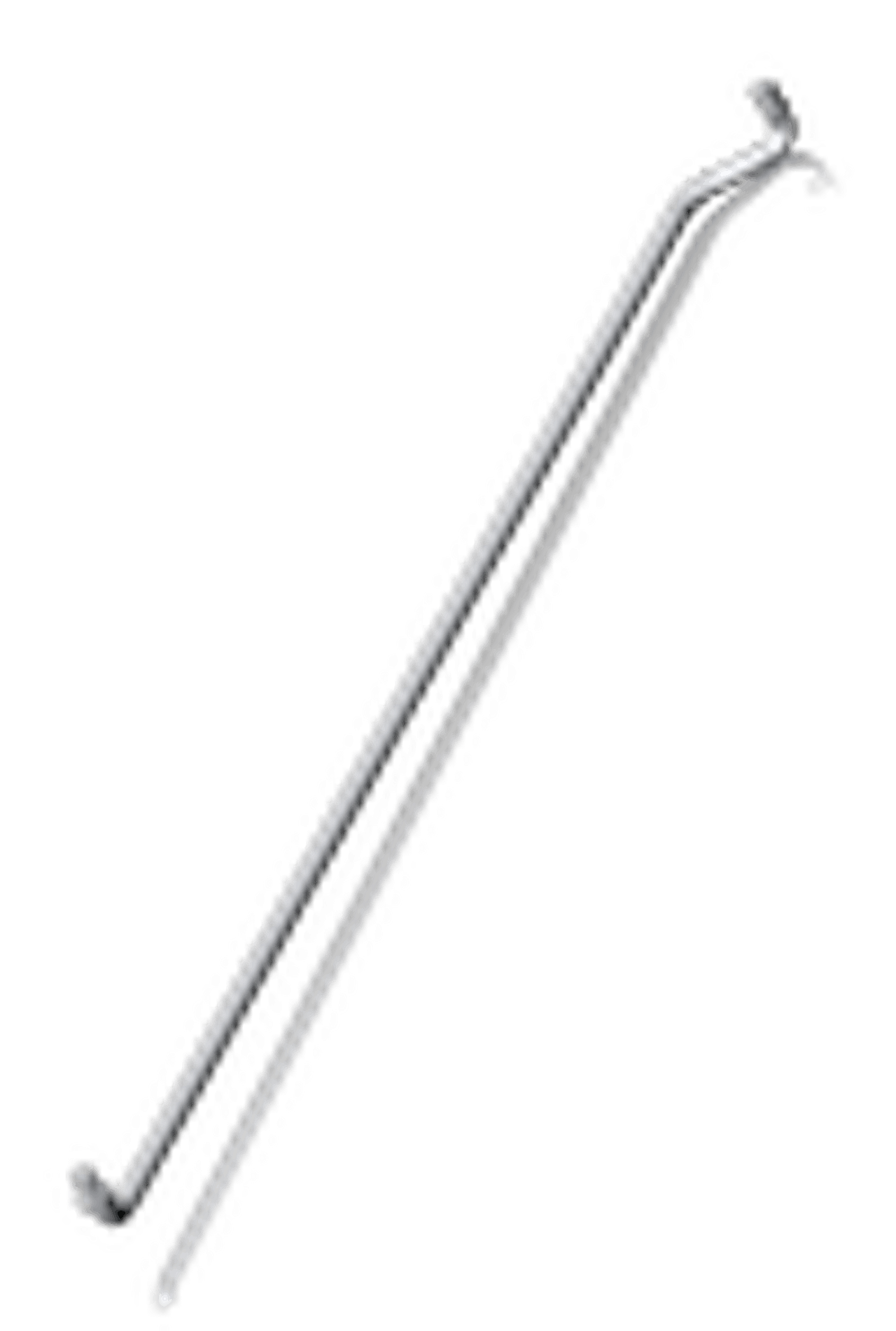

Ideal for locking fasteners into a secure position, cotter pins are a popular wire form fastener that is used in aerospace, military and defense, and commercial use. MW offer stock, standard, and custom cotter pins.

-

Available in a wide variety of sizes, hitch pins are frequently used in the automotive, agriculture, and power tool industries.

-

One of the most versatile wire forms, D rings can be made of various thicknesses of metal wire and are used across industries, including in tie-down systems, pet collars, and anytime an anchor is needed to secure a cord or rope in position.

-

Frequently called safety hooks, S hooks have a telltale S shape and are used in both commercial and consumer use to hang items such as cords, cables, and hoses. In industrial applications, S hooks are used to keep cables at a safe distance from work areas.

-

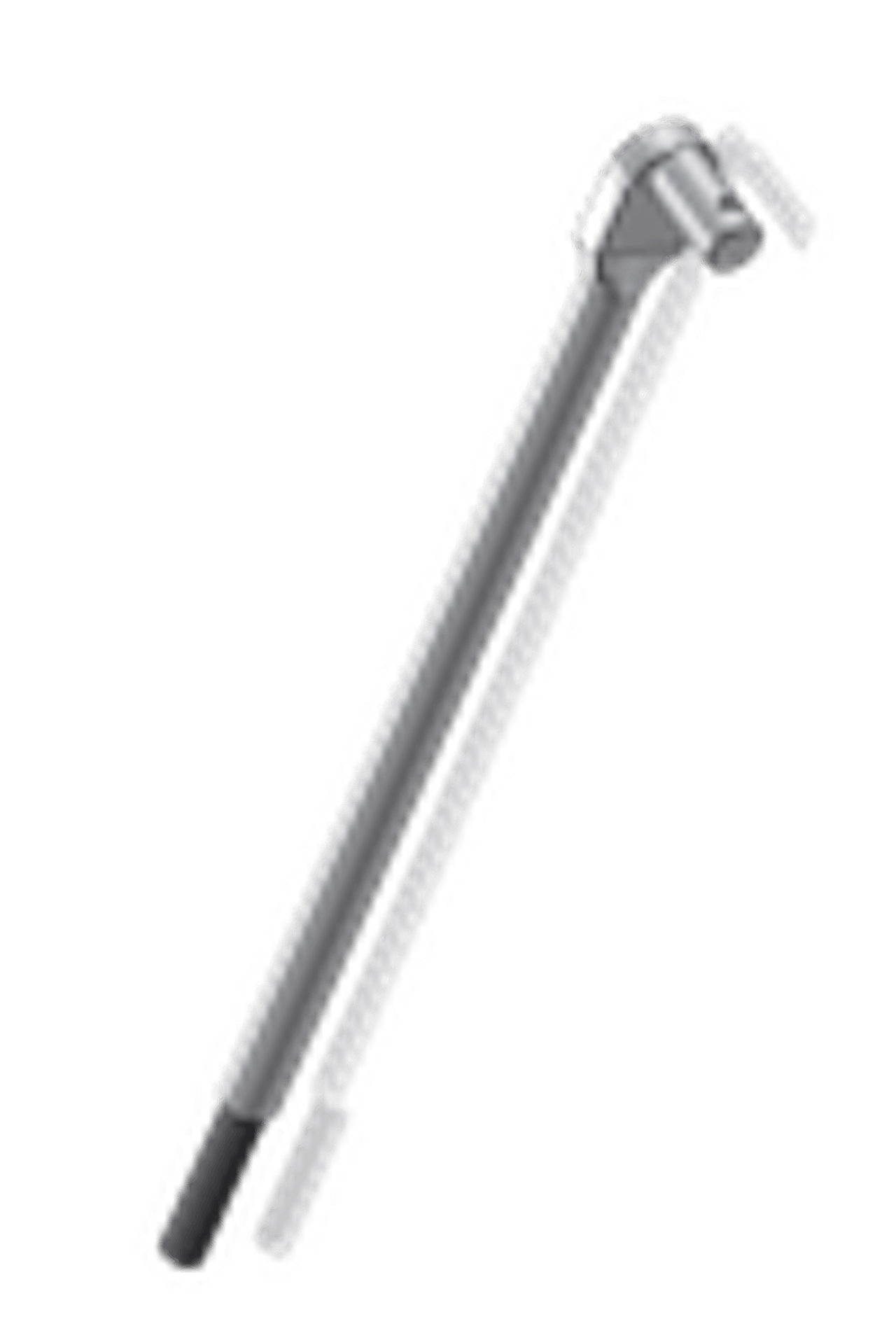

Headed Wire Forms

Headed Wire FormsHeaded wire forms allow for many different applications. We offer a variety of head styles to choose from, or let us help you design the perfect custom solution

Available Specifications

Standard Diameters: 3/32″-1″

Metric Diameters: M3-M12

Standard Lengths: 1/2″-144″

Metric Lengths: 12.7mm-3567mm

Materials: Low carbon steel, stainless steel -

CNC Multiple Bend Wire Forms

CNC Multiple Bend Wire FormsWhen your wire form requires multiple bends, our CNC machining capabilities can handle the job. We can also help you design and prototype your wire forms.

Available Specifications

Standard Diameters: 3/32″-1″

Metric Diameters: M3-M12

Standard Lengths: 1/2″-144″

Metric Lengths: 12.7mm-3567mm

Materials: Low carbon steel, stainless steel, exotic materials -

Formed and Stamped Wire Forms

Formed and Stamped Wire FormsFormed and stamped wire forms may require welding, stamping, threading or other processes in their production. At Elgin, we have the presses and automation necessary to produce the formed and stamped wire forms to meet your needs.

Available Specifications

Standard Diameters: 3/32″-1″

Metric Diameters: M3-M12

Standard Lengths: 1/2″-144″

Metric Lengths: 12.7mm-3567mm

Materials: Low carbon steel, stainless steel, exotic materials -

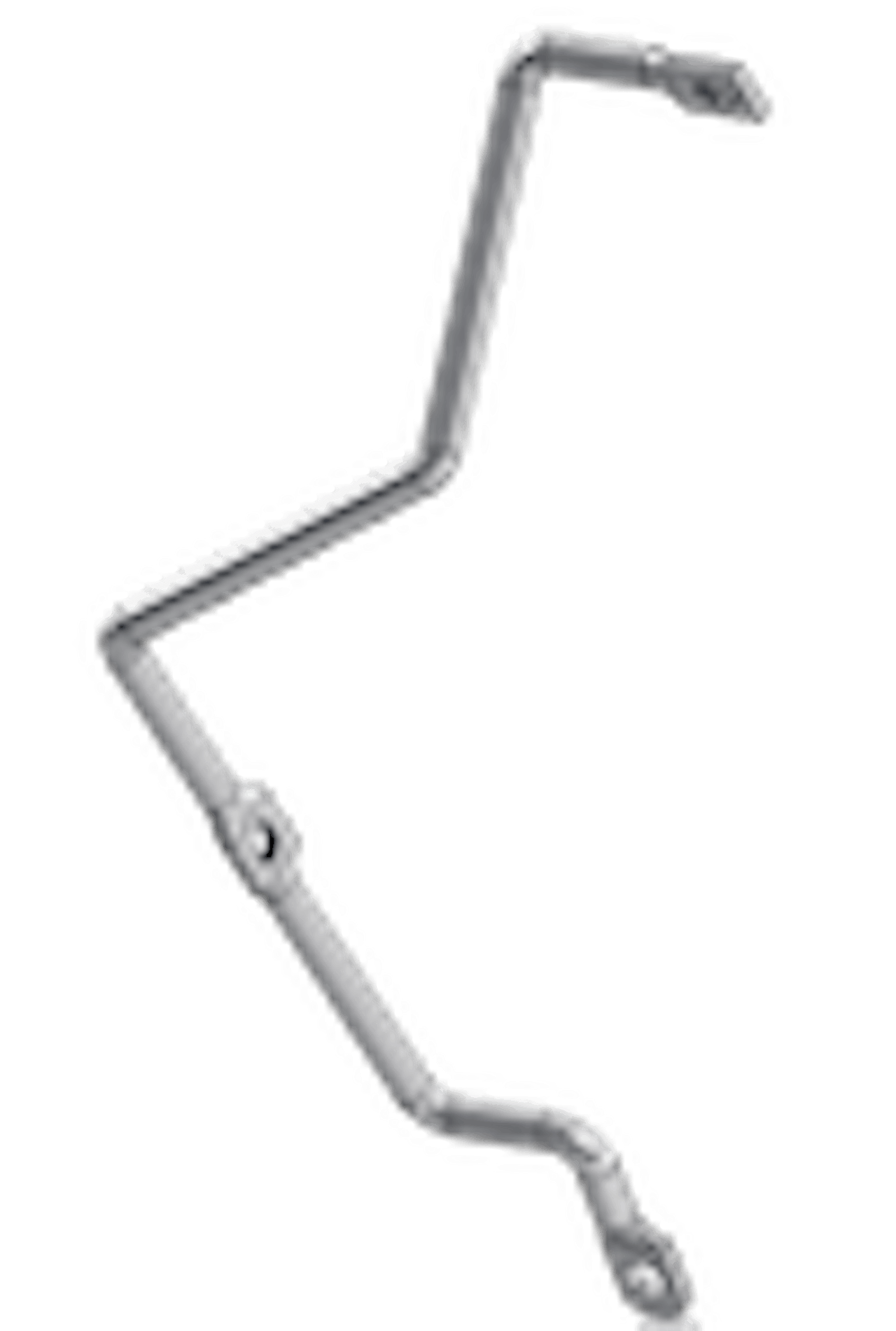

Linkage Arms

Linkage ArmsUse linkage arms to connect parts and pieces for your project. Elgin offers dozens of options, including a variety of head, thread, and linkage configurations.

Available Specifications

Standard Diameters: 3/32″-1″

Metric Diameters: M3-M12

Standard Lengths: 1/2″-144″

Metric Lengths: 12.7mm-3567mm

Materials: Low carbon steel, stainless steel, exotic materials

Wire Fastener & Wire Forming Companies

MW has no fewer than 10 locations across the United States that can support wire form manufacturing, ensuring that you have a reliable source for any part you need. Our top wire form manufacturers, however, are Western Wire and Northern Wire. Known for their ability to support a wide range of product sizes and complex bends, Western Wire and Northern Wire can support products made from wire as small as .010" and up to 12 feet in length.

Industrial Wire Forming and Wire Fastener Products

With over 100 years of experience, Western Wire is known for their cotter and hitch pins. Cotter pins and hitch pins in standard sizes are in-stock, with same-day shipping available.

Western Wire's capabilities go far beyond cotter and hitch pins, however. They are also experts S-hooks, D-rings, hog rings, and more with custom build-to-spec for specialty wire fastener products, with the ability to manufacture products in wire diameters from .010 to .625 inches (.3 mm to 16 mm).

Contact Western Wire for details on their standard products and custom capabilities.

CNC Wire Bending & Large Wire Forms Up to 12'

Located in Merrill, WI, our Northern Wire location specializes in CNC wire bending, including specialty bends for wire form fasteners, wire forms, and welded wire products. They are especially skilled at larger diameter wire products, or large length wire forms. Their in-house wire bending services and secondary processes include everything from drilling and chamfering to tapping and threading.

In addition to wire form fastener products, Northern Wire also offers standalone zinc plating services for a wide variety of products.

For more information, contact Northern Wire.

Wire Form Manufacturing Capabilities

Wire forms have the unique ability to join complex products with tough design constraints. MW Components offers a variety of wire forms to suit your needs, including formed and stamped wire forms, multiple-bend forms, headed forms, and linkage arms.

We have the equipment and capabilities to produce the wire forms you're looking for, in the sizes, configurations and materials you need. With complete control of production, we’re a wire forming manufacturer that ensures both a high-quality product and fast turnaround.

Custom Wire Form Manufacturing

Wire forms are created by forming and pressing wire into specific desired configurations in order to complete a job or perform a function. As complex design experts, MW has the capability to produce wire forms with our advanced machinery, allowing for custom wire form production at ultra-high speeds.

- Multi-axis CNC machining and CNC wire bending services

- Fast turnaround times

- Lengths from 1.5" to 12' and diameters ranging from .125” to 000”, including many metric sizes

- Variety of material grades

- High quality products ensured with a robust QA process and quality assurance systems

Materials

We use the highest grades of spring wire in our custom products. Carbon steels include material types such as music wire, basic, hard drawn and oil-tempered chrome silicon & vanadium. We work in a variety of stainless materials from 302 Stainless to 316 SS, 17-7 PH and even more exotics. Material certifications available on request.

Finishing

We perform several finishing and coating processes as needed for your application. Some finishes we offer are listed below. If you require a finish not listed here, contact us for a custom quote and we will work with you to get the performance properties you require.

Industries

Wire forming and custom wire bending products are used in markets such as lawn and garden, power equipment, agriculture, industrial, health care, appliances and furniture, farm equipment and consumer goods.

Frequently Asked Questions

What are wire forms?

Wire forms are items made out of shaped wire. Wire forms re typically created by bending a piece of metal wire and can be as simple as a straight line cut to a desired length, or a form with multiple bends and enhancements, such as threading.

What is wire forming?

Wire forming, also called wire rolling, is a metal fabrication process where wire material is bent or formed into a specified shape and cut to the preferred length. This process is generally performed using the aid of computer software which guides the forming parameters. Wire forms join products with tough design constraints.

What is CNC wire bending?

CNC wire bending is a manufacturing process that uses Computer Numerical Control (CNC) technology to precisely bend wire into various shapes and configurations. This technique is widely used in industries such as automotive, aerospace, electronics, and furniture production, where precise and repeatable wire forms are needed. While CNC wire bending refers to a specific process for shaping wire, it is a type of wire forming and the terms are often used interchangeably

What are wire forms used for?

Wire forms are used in nearly every industry and application. The most recognized wire forms include hangers, springs, and pins, but other wire forms can be used as lightbulb filaments, electrical contacts, and more.

Why choose MW for wire forms?

At MW Components, we form wire from a coil of metal and turn it into parts at ultra-high speeds. We’re complex design experts, offering front-end engineering support for wire forming. Show us your blueprint, and our engineers can optimize it. With several wire bending companies as part of our portfolio, our custom wire forming expertise allows us to produce the product you need, exactly as you need it.

We have on-site CNC wire bending services, secondary operations and plating. Single-source production provides quality control. We have the equipment and skill to form, fabricate, machine, cut, assemble and weld your product components.

Questions? Ask one of our experts.

We're not just a manufacturing company. We invest heavily in our customers, including hiring the best engineers and manufacturing professionals so you have access to the resources you need. Please reach out to our team with any questions you may have, including design and optimization questions. We'll make sure you get to someone who can help.