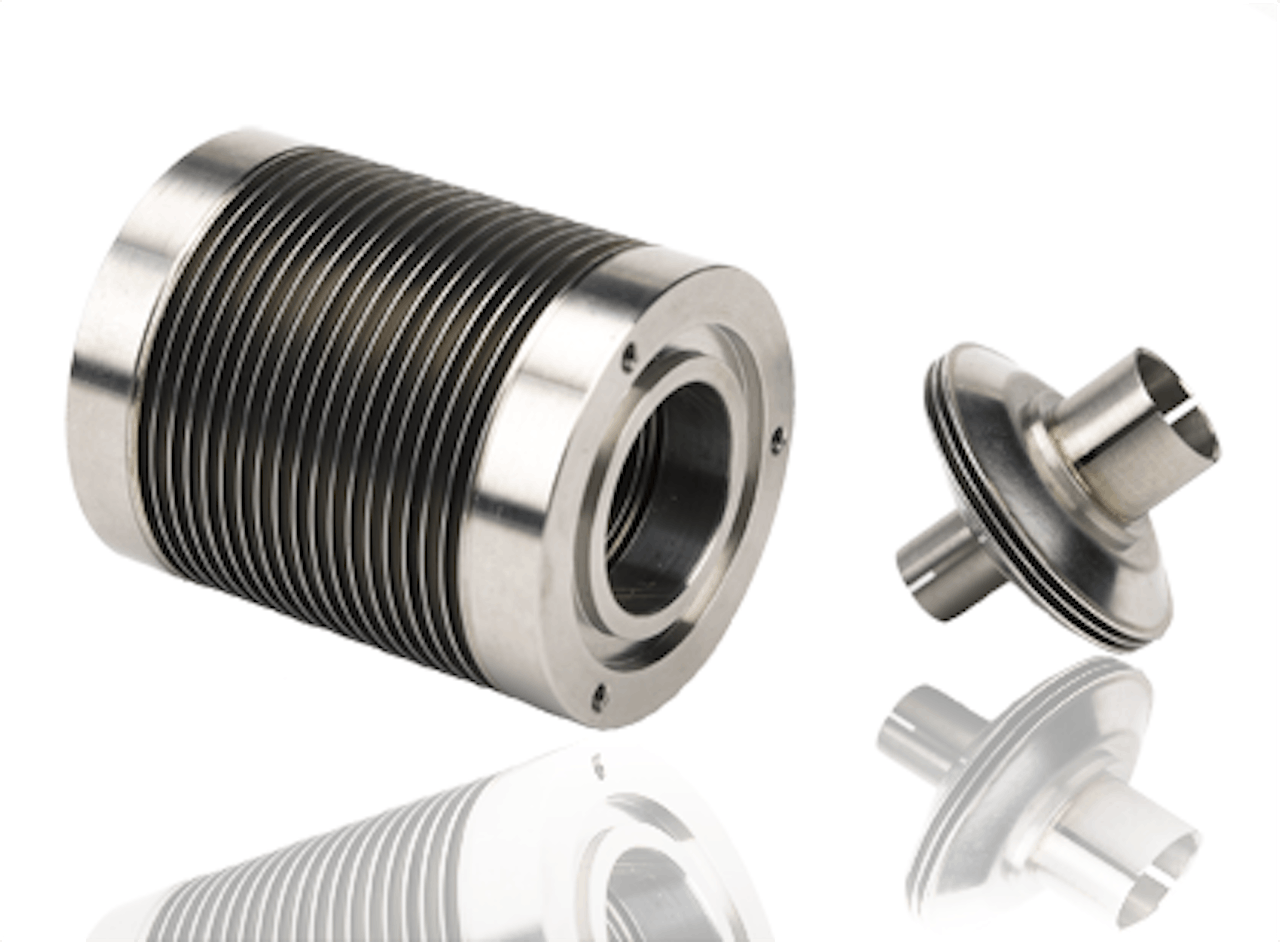

Products > Bellows / Couplings

Welded Stainless Steel Bellows

Stainless steel bellows offer the best price-to-performance ratio of any material. Stainless steel bellows maintain their high strength capability and custom design with varying thicknesses. MW Components offers superior welding technology, including micro-welding to ensure that each edge welded bellows assembly meets our customers' requirements.

CUSTOM MANUFACTURING

Custom Stainless Steel Bellows

Our stainless steel metal bellows are produced using any of the following materials (AM350*, 316L, 347, 321, and 304L SS).

Our facilities specialize in custom component production, meaning we offer a variety of specialty finishes and materials as well as a selection of optional manufacturing services. Some of these services include design, tooling, CAD modeling, and various secondary machining processes.

Send us your specs or configure a part.

Stainless Steel Bellows Manufacturing

Our edge-welded bellows are produced by stamping metal diaphragms, welding inside diameters to form convolutions, and finally welding the outside diameters. This creates a very strong, yet flexible mechanical conduit compatible with liquids and gases. Various diaphragm thicknesses are available as well as two-ply construction for higher pressures. More information on this process can be found on our Edge-Welding Technology page.

We can build assemblies using stainless steel from an ultra-high vacuum (UHV) to positive pressures. Whether our customer requires an actuator, volume compensator, expansion joint, or flexible seal, We even design and manufacture to customer specifications.

With custom capabilities of size, shape, and connections, the flexibility of stainless steel bellows is endless. MW can also offer designs configured from our standard sizes as well. Over eighty standard diaphragm sizes makes finding the right fit is easy, timely, and cost-effective. Add any type of machined flange or end piece to the bellows assembly in order to simplify installation.

Edge Welded Stainless Steel Bellows Specifications

Materials

AM350 is a high-strength alloy that produces highly accurate and repeatable results with an operating range from -100°F to 800°F. The metal is slightly magnetic and is used in non-acidic environments.

For cryogenic and non-magnetic applications, we prefer 316L stainless steel material. It operates from -420° up to 800°F. 316L material also offers better corrosion resistance for acidic applications.

321, 347, and 304L stainless steels are available, yet are typically used for legacy, drop-in replacement applications.

| Specification | Range |

|---|---|

| Material | AM350, 316L, 347, 321 or 304L SS |

| Thickness | 0.002″ and up every 0.001″ |

| Standard Leak Rate | <1×10-9 std. CC He/sec. |

| Size (OD) | 0.358″ (9.0932mm) to 22.205″ (564mm) |

| Size (ID) | 0.198″ (5.029mm) to 19.921″ (505.99mm) |

| Shapes | Round standard. Non-round available; ask an MW expert. |

| Length | Up to 96 inches (244 cm) |