Welding

What are Welding Services?

Welding involves the joining together of two materials using heat or pressure, which creates a bond once the materials have cooled. There are many forms of welding. They are separated by the type of energy or amount of heat needed to perform the operation. Lower-heat metal joining processes include brazing and soldering, while traditional welding is performed using high- heat. Other adhesion services include electron-beam welding and adhesive bonding.

Welding is often used to join metals; however, other materials like thermoplastics also respond well to welding applications.

Have questions about this or other services?

Explore Our Welding Services

Laser Welding

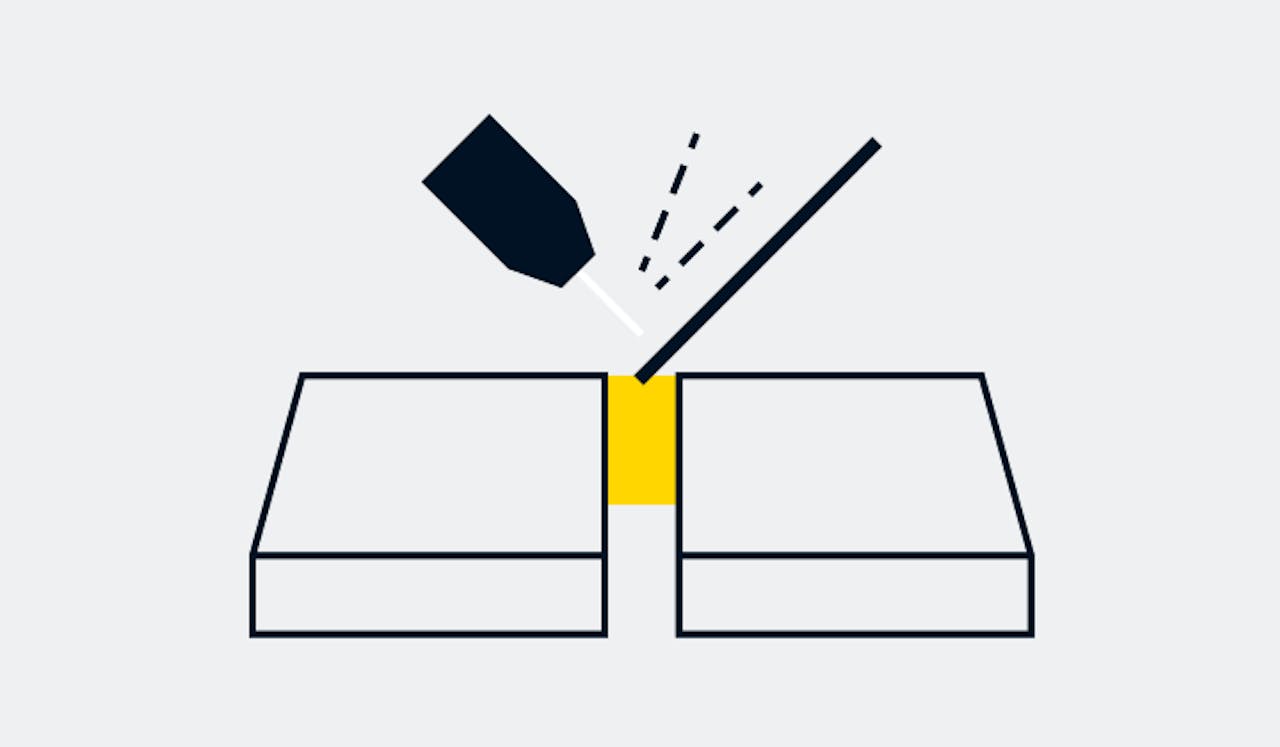

Laser welding or laser beam welding is a joining process used with metal or thermoplastics through the application of a directed laser.

TIG Welding

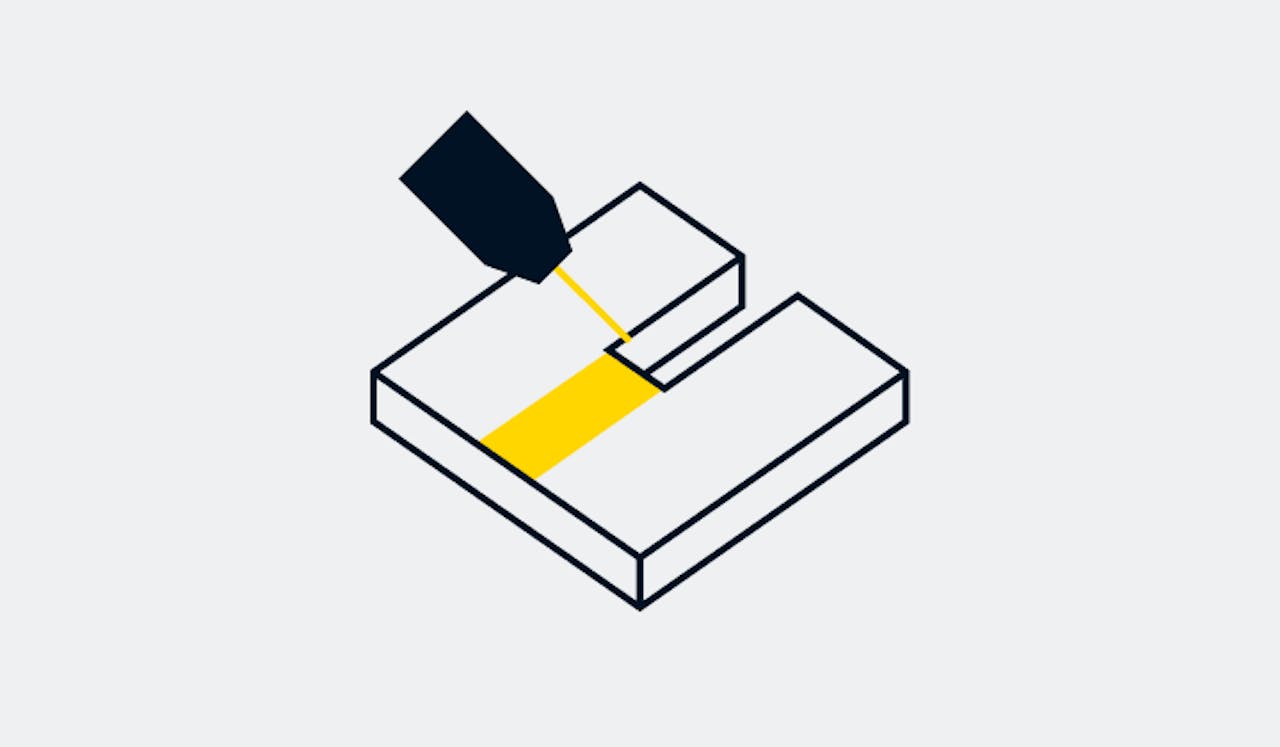

Tungsten Inert Gas (TIG) welding is an arc welding process often used for aluminum. This process produces a high-quality weld using a tungsten electrode and protective gas which is used to protect from oxidation and contaminants during the weld process.

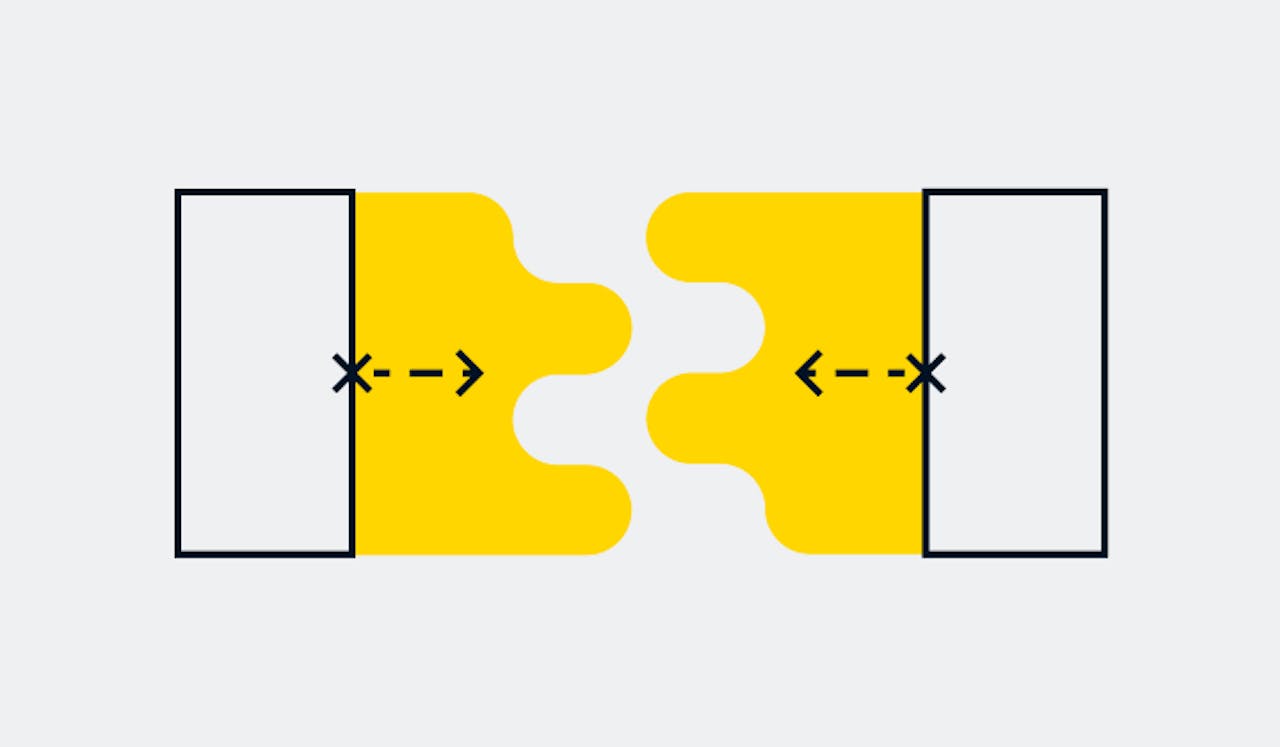

Adhesive Bonding

Adhesive bonding is the process of joining two surfaces with glue, epoxy, or plastic materials and using heat, pressure, or evaporation to cure and set the bond.

Electron-Beam Welding

Electron-beam welding fuses materials together using high-velocity electrons focused into a beam, causing the materials to melt, merging the two pieces into one.

Brazing & Torchless Brazing

Brazing is used to join metals by pouring a molten filler metal into the cavity between the joints. Some of our locations perform torchless induction brazing which can be used to join sub-assemblies. The assemblies can then be soft soldered to additional components.

Soldering

Soldering joins two or more materials together by filling the joint between the two with a melted filler metal. Unlike traditional welding methods, soldering does not require melting the original materials.

Micro-Welding

Micro-welding is used to weld small areas on metal components like metal bellows. This is a precision welding process which ensures that possibly damaging heat is localized to the weld-area exclusively, minimizing the risk of heat damage to the remainder of the component.

Industries Served

These machining processes are used most often in the production of precision components designed for use in very specific applications. Our machined components are found in a variety of industries.

Custom Applications

While most of our machining services are traditionally used to produce metal parts like springs, fasteners, bellows, and similar components, we will gladly take on additional jobs outside our standard scope of work that require similar welding services.

Ready to Get Started?

Request a quote and start your journey with MW Components.