BellowsTech

Edge-Welded Bellows

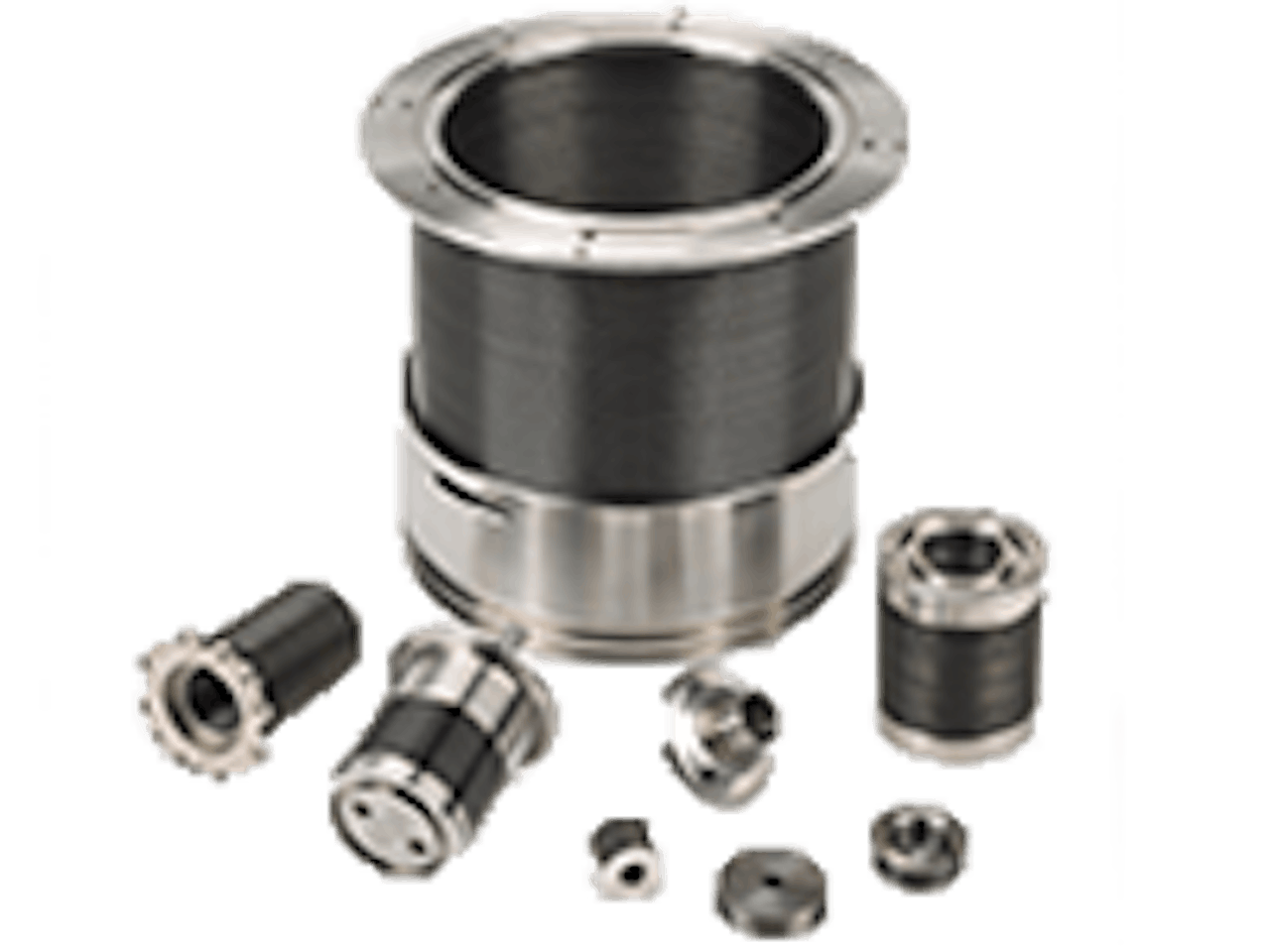

BellowsTech is a premier manufacturer of high-quality, dependable edge-welded bellows and assemblies. The expert engineers at our BellowsTech location partner with you to produce truly optimized designs for fast prototyping or full production runs. They can manufacture all sizes, shapes, and material combinations to fit your unique applications.

Review our Edge-Welded Bellows Brochure for more information on our custom metal bellows manufacturing capabilities. When you're ready to order, request a quote to work with our expert engineering staff to develop custom bellows and assemblies or shop standard sizes online.

Request a Quote Shop Standard Bellows Sizes

Edge-Welded Metal Bellows Manufacturer

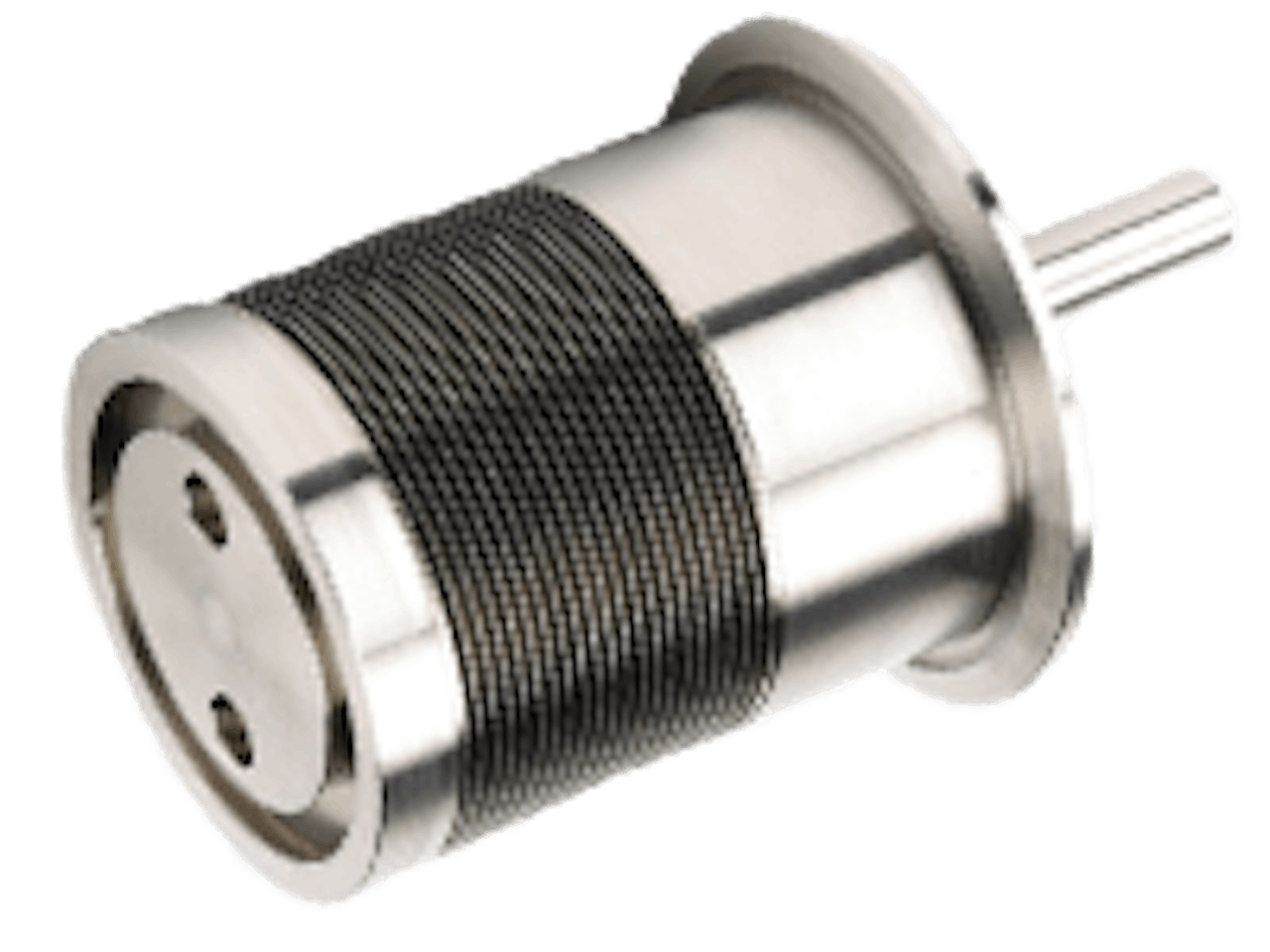

Metal bellows provide an all-metal pressure barrier and seal that flexes in one or more directions. Edge-welded metal bellows provide the most flex in the smallest amount of space of any bellows technology on the market with up to a 90% stroke length. With various materials and configurations, BellowsTech’s edge-welded bellows can achieve the pressure, temperature, and leak rate requirements that our customers require.

BellowsTech offers metal bellows from a variety of materials including titanium, Hastelloy, Inconel, and stainless steel. As an ISO 9001:2015 certified manufacturer, our edge welded bellows provide high accuracy and repeatable results for demanding industries such as aerospace, medical, energy, and more.

Our Products

-

Edge-welded bellows offer up to 90% stroke length plus other benefits such as have exceptional medical compatibility, high temperature endurance.

-

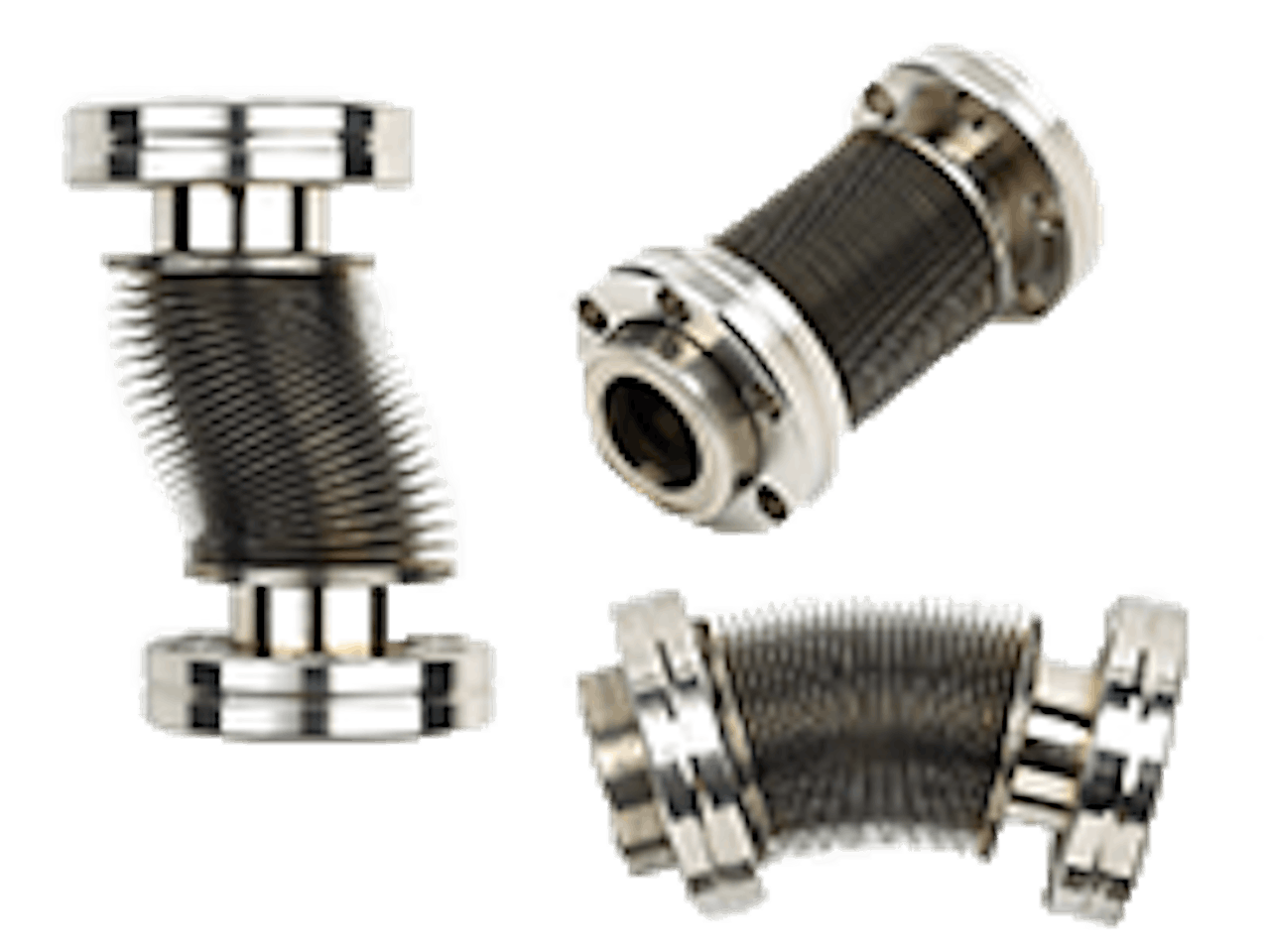

Our A-style bellows couplings have flat end plates and are available as stock parts. Lead times for AM350 and 316L stainless steel are 3-4 weeks.

-

Our E-style bellows couplings have tubed end plates and are available as stock parts. Lead times for AM350 and 316L stainless steel are 3-4 weeks.

-

CF style assemblies have conflat flances that make them ideal for ultra-high vacuum applications. Shop standard parts and request a quote.

-

Edge-welded inconel bellows offer excellent corrosion resistance and temperature performance. Learn more or request a quote.

-

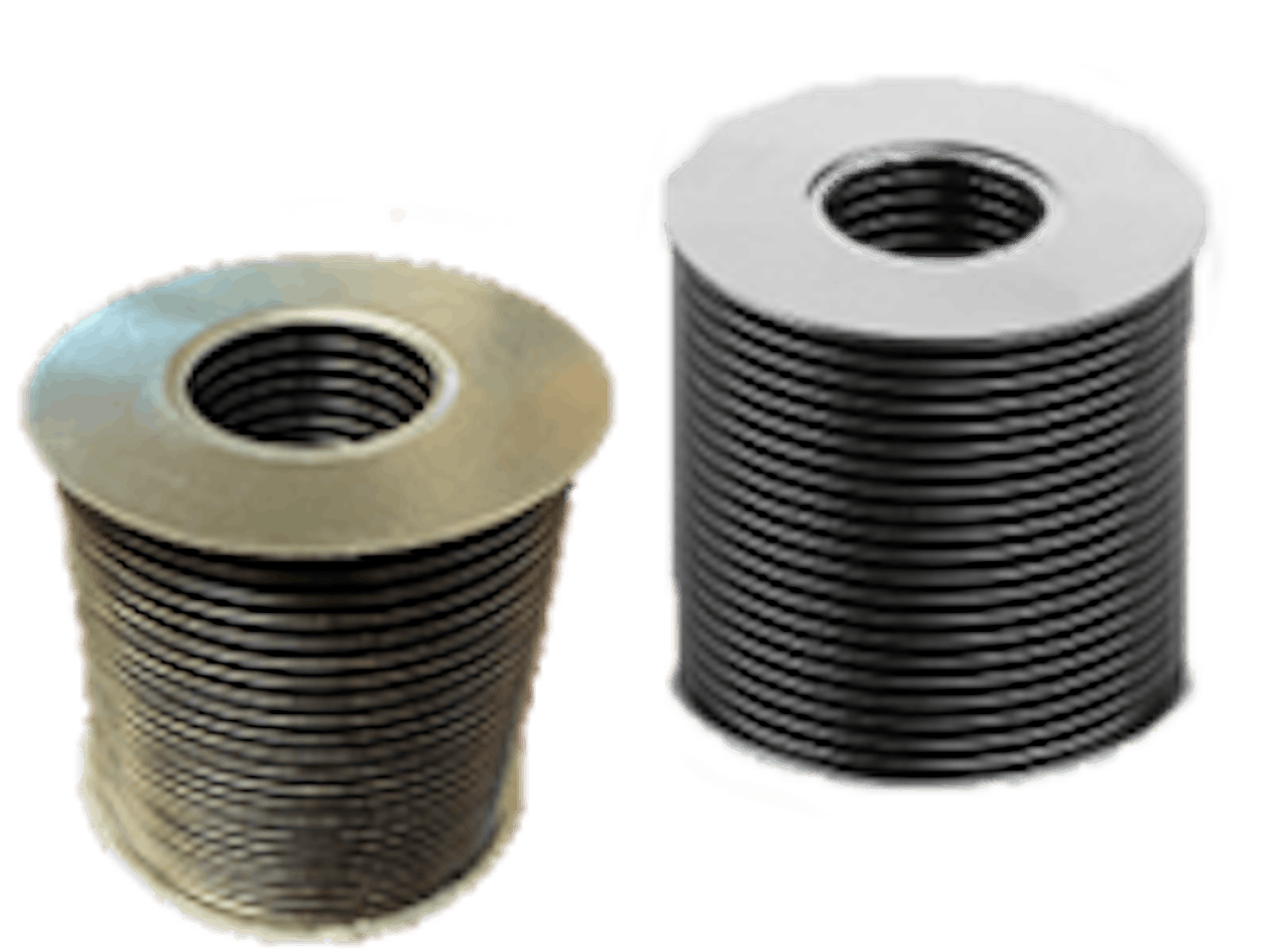

Stainless steel bellows offer high strength and the ability to select from varying thicknesses. We also offer micro-welding for stainless steel bellows,

-

Hastelloy offers exceptional chemical compatibility, making hastelloy bellows suitable for applications with specialized or corrosive media.

-

Titanium bellows are strong, lightweight, and have superior media compatibility. They are ideal for aerospace and medical applications, among others.

Compliance, Quality & Certificates

BellowsTech® consistently receives exceptional quality ratings from it’s OEM manufacturing customers worldwide. We have to be reliable. BellowsTech® products are used in mission-critical applications in aerospace, defense, medical, and oil and gas.

We believe in continuous improvement and practice lean manufacturing guidelines. We recognize the importance of ITAR, RoHs and DFARS compliance. BellowsTech® is ISO 9001:2015 certified.

Contact Us

We offer expert design support to ensure your bellows fit your application. Contact us for more information about custom bellows manufacturing today.