Products > Bellows / Couplings > Metal Bellows > Edge-Welded Bellows

Welded Inconel Bellows for High Temperature Applications

Inconel® is a nickel-based alloy with superior corrosion resistance and temperature performance to stainless steel. Inconel® Bellows using edge welded technology are designed for applications that require excellent corrosion resistance properties, such as valve or down-hole tool applications that are exposed to hydrogen sulfide. These bellows are often used for test stands, high-temperature exhausts, and oil and gas applications.

CUSTOM MANUFACTURING

Custom Inconel Bellows

Our facilities specialize in custom component production, offering a variety of specialty finishes and materials as well as a selection of optional manufacturing services. Some of these services include design, tooling, CAD modeling, and various secondary machining processes.

Send us your specs or configure a part.

Inconel Bellows Manufacturing

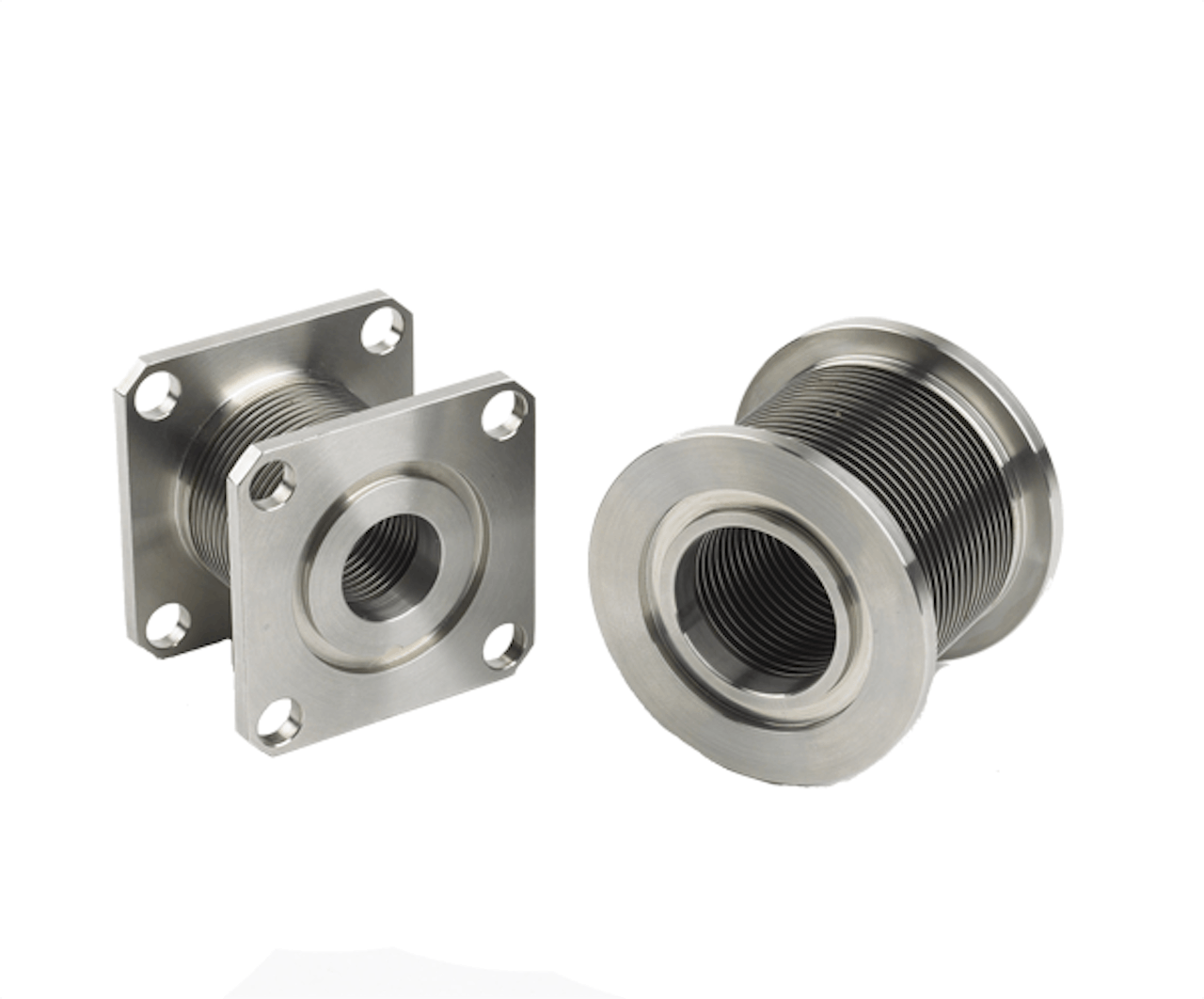

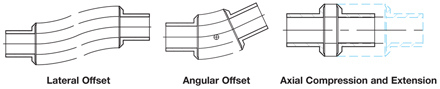

The excellent high-temperature survivability and custom design of our Inconel bellows make them a cost-effective solution for assemblies requiring a flexible connection that can withstand temperatures greater than 1000°F, with Alloy 625 offering the highest standard temperature rating. With the flexibility to customize, MW can manufacture and weld custom fittings, flanges, and weld rings to its Inconel bellows to make customer installations easy and seamless. A variety of diaphragm options and thicknesses as well as the ability to manufacture multi-ply bellows construction increases the temperature and strength capabilities while maintaining most of its stroke length. WM Components works with customers to choose the right alloy based on the customer’s requirements.

*INCONEL® is a registered trademark of Special Metals Corporation.

Looking for information on standard sizes? To view a list of standard die sizes MW uses, visit our standard edge-welded bellows diaphragm size page.

Edge-Welded Inconel Bellows Specifications

| Specification | Range |

|---|---|

| Material | Alloy 625 (Inconel® 625)+ or Alloy 718 (Inconel® 718)+, Alloy X750 (Inconel® X750) |

| Thickness | 0.004″ and up every 0.001″ |

| Standard Leak Rate | <1×10-5 std. CC He/sec |

| Size (OD) | 0.358″ (9.0932mm) to 22.205″ (564mm) |

| Size (ID) | 0.198″ (5.029mm) to 19.921″ (505.99mm) |

| Shapes | Round standard. Non-round available; ask an MW expert. |

| Length | Up to 96 inches (244 cm) |