Products > Bellows / Couplings > Helical / Beam Couplings

MC Series Flexible Beam Couplings

This versatile series of couplings provides you with a full range of torque capacities and bore sizes, all with 1/32-inch parallel misalignment capability. These couplings attach to shafts with your choice of integral clamps or set screws. Combine this with optional keyways and the MC Series is tailor-made for your application. From medium-duty (aluminum) to heavy-duty, (stainless steel), this series provides solutions for a wide range of applications. From pumps and lead screws to conveyors, chances are an MC Series coupling/coupler will fit your needs.

CAD files for stock and standard MC Series beam couplings are available for download in MW OnDemand.

CUSTOM MANUFACTURING

Custom Electrical Contacts

Custom beam couplings or Helical couplings offer many benefits including, choice of material composition, simplification of assembly, and customizable attachments and tolerances suited to your specific end-use. MW specializes in custom component manufacturing, providing you with the right features to ensure proper performance. Whether you need to eliminate endplay or spring, ensure zero backlash, need to increase torsional stiffness, or reduce windup, we can create the right custom coupling for your specialized need made to your exact specifications.

Send us your specs or configure a part.

Characteristics

Beam or Helical couplings are flexible shaft couplings designed to transmit torque between shafts. Due to their curved beam configurations which allow angular movement, they can accommodate misalignments and axial motion, unlike traditional rigid couplings.

Features

- Industrial motor shaft couplings

- Large parallel misalignment capacity

- High torque capacity

- Large shaft diameters

- Keyways available

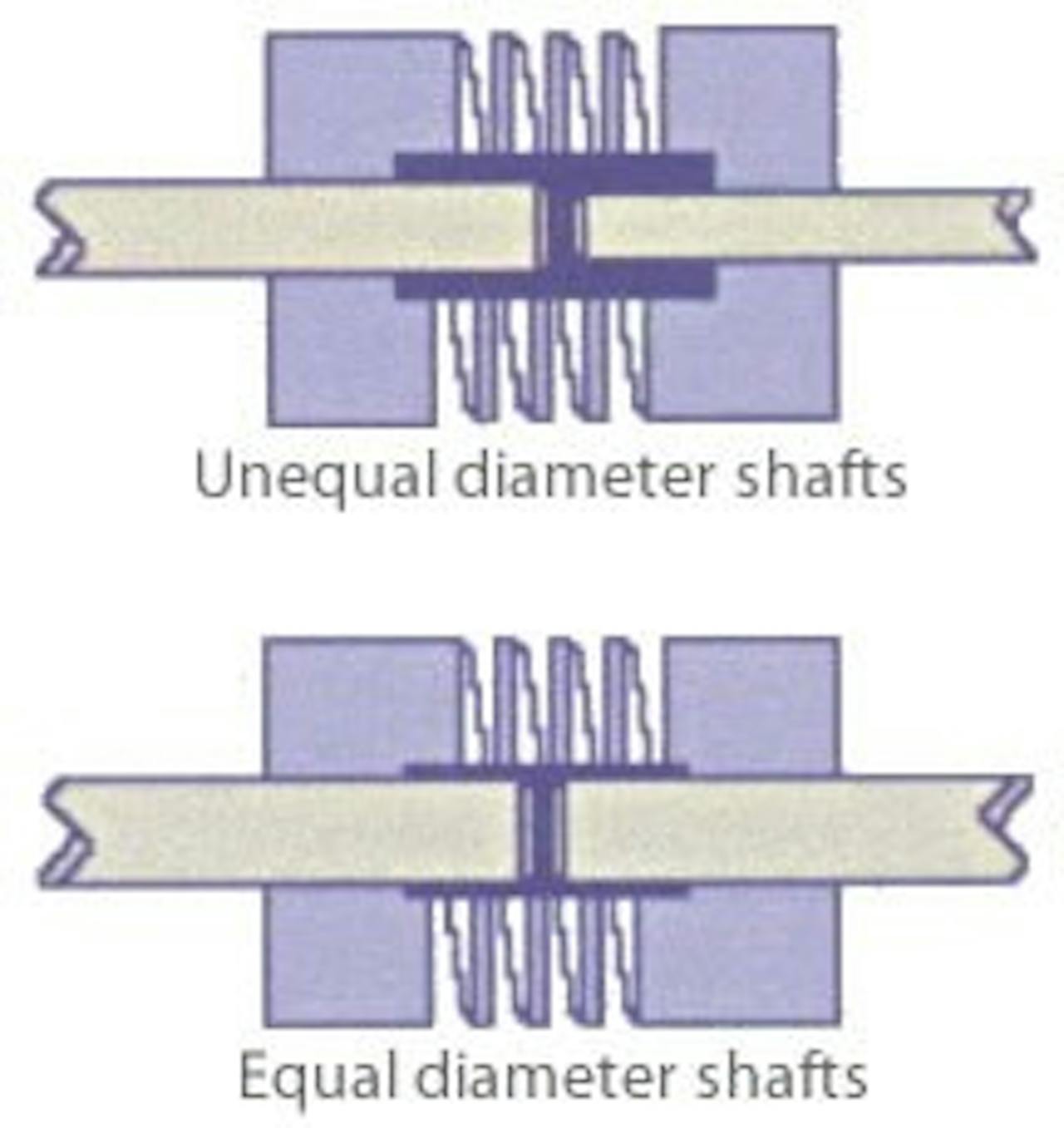

Relief

- Major and minor diameter shafts may enter flexure area during operation

- Dark areas indicate relief within the coupling interior

Applications

Good for encoder/resolver applications, moderate torque pump, lead screw, and various other applications. Also for pump, conveyor systems, and industrial processing equipment, where absolute reliability is required. Anywhere a rugged, tough, long-lasting coupling is needed.

Materials

Available in 7075-T6 Aluminum Alloy or 17-4 PH Corrosion Resistant Steel (CRES).

Attachments

Integral Clamp or Set Screw (2 at 120°), Keyways Optional

Misalignment Compensation

Technical Data - Bore Ranges

STANDARD BEAM COUPLING MANUFACTURING & CONFIGURATIONS

Manufacturing

Our MC beam couplings are produced using either 7075-T6 Aluminum Alloy or 17-4 PH Corrosion Resistant Steel (CRES). Specialty materials and services are available for custom coupling production. Multiple attachment styles are available for added functionality. Torque range, bore ranges, operating temperatures, speed, and other performance factors will vary depending on the configuration chosen.

For more details on available coupling configurations, review the list below for a side-by-side comparison, view our Standard Coupling Comparison Guide below.