Cleaning & Polishing

MW performs component cleaning and polishing services to ensure the appropriate final finish is achieved. Some examples of these services include deburring and shot peening, which are also used to increase a metal products' toughness and overall performance.Have questions about this or other services?

Cleaning & Polishing Services

Parts Cleaning

Our aqueous parts washing system allows us to clean and dry components after manufacturing. The computer-aided system uses a combination of agitation, rotation, submersion, jet-spray, and ultrasonic cleaning techniques to remove cutting fluids, metal shavings, and debris and leave your parts completely clean, dry and ready for use.

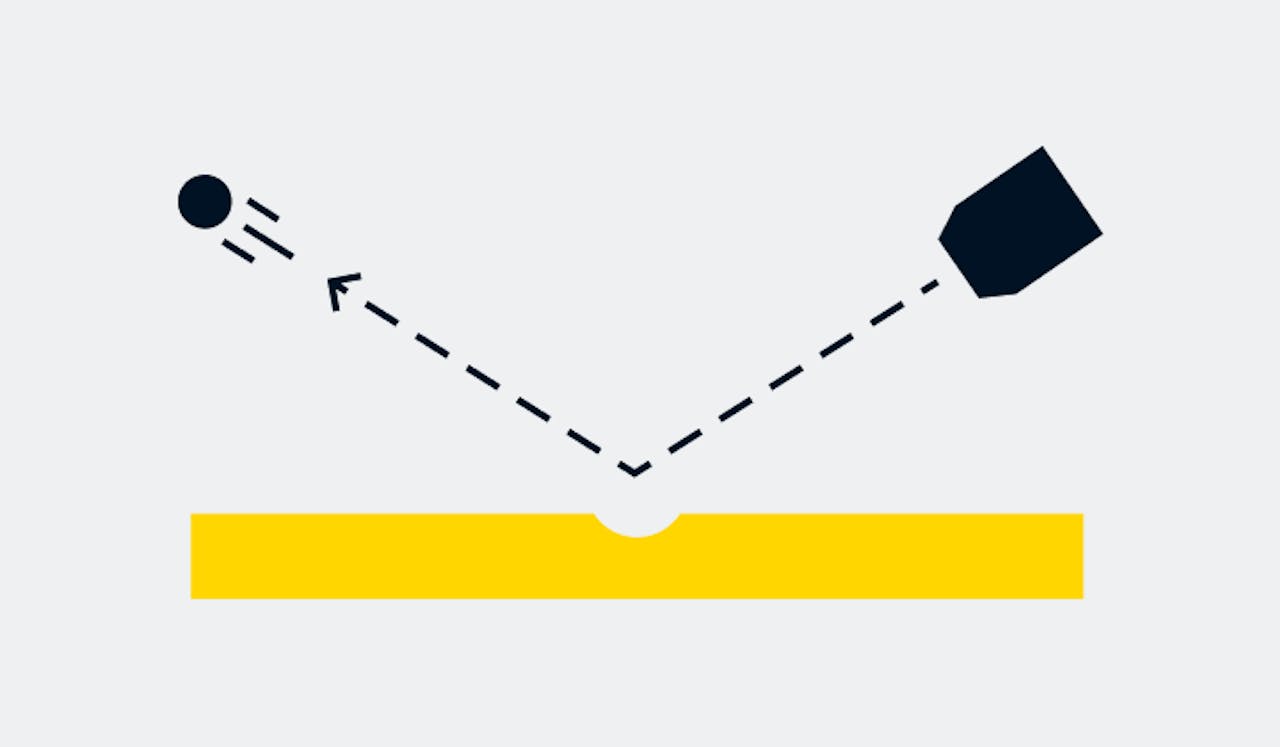

Shot Peening

Shot peening refers to a process used to create a stress layer on metal parts to increase durability. In this process, small round materials or shot are used to repeatedly strike the surface of the part to increase hardness and strength. Shot can be composed of anything from ceramic or glass to metal.

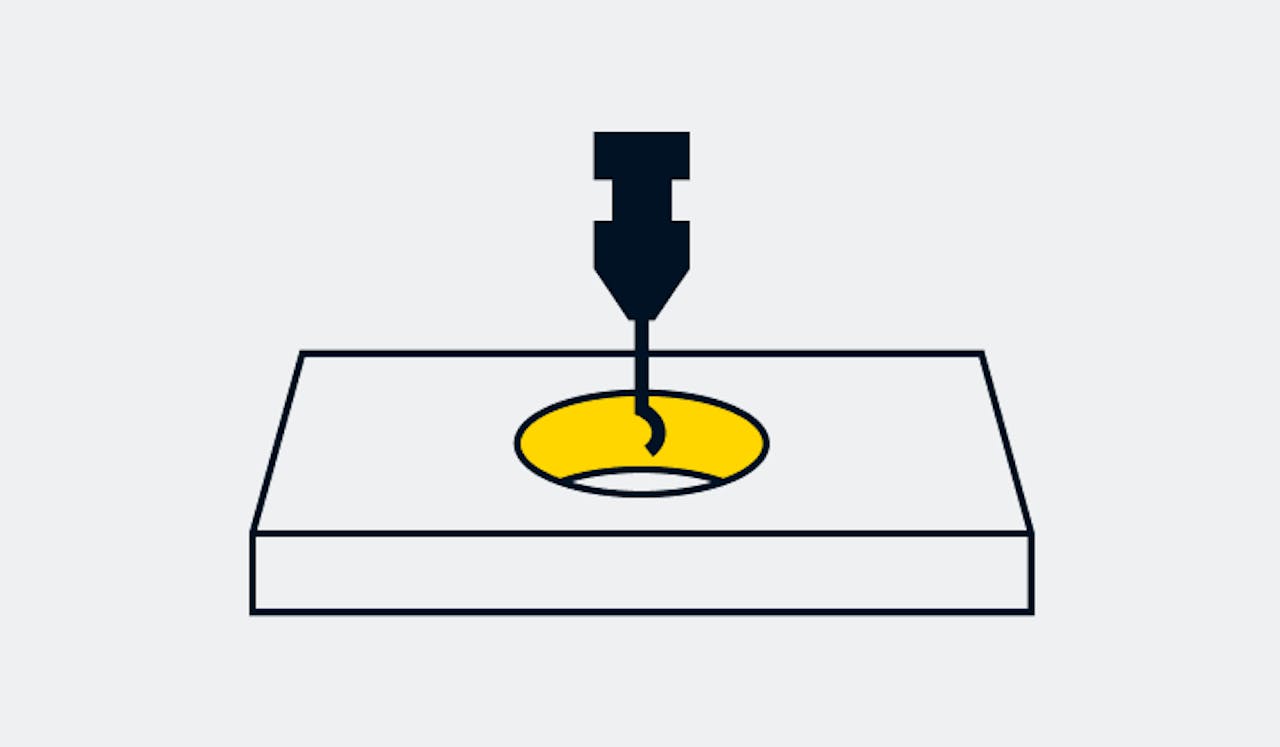

Deburring

Deburring is the process of removing any raised edges or rigidity remaining on a product’s surface after a manufacturing process has been completed.

Industries Served

Our cleaning and polishing services are used to finish products in various industries. Below are some of the industries which routinely rely on our products.