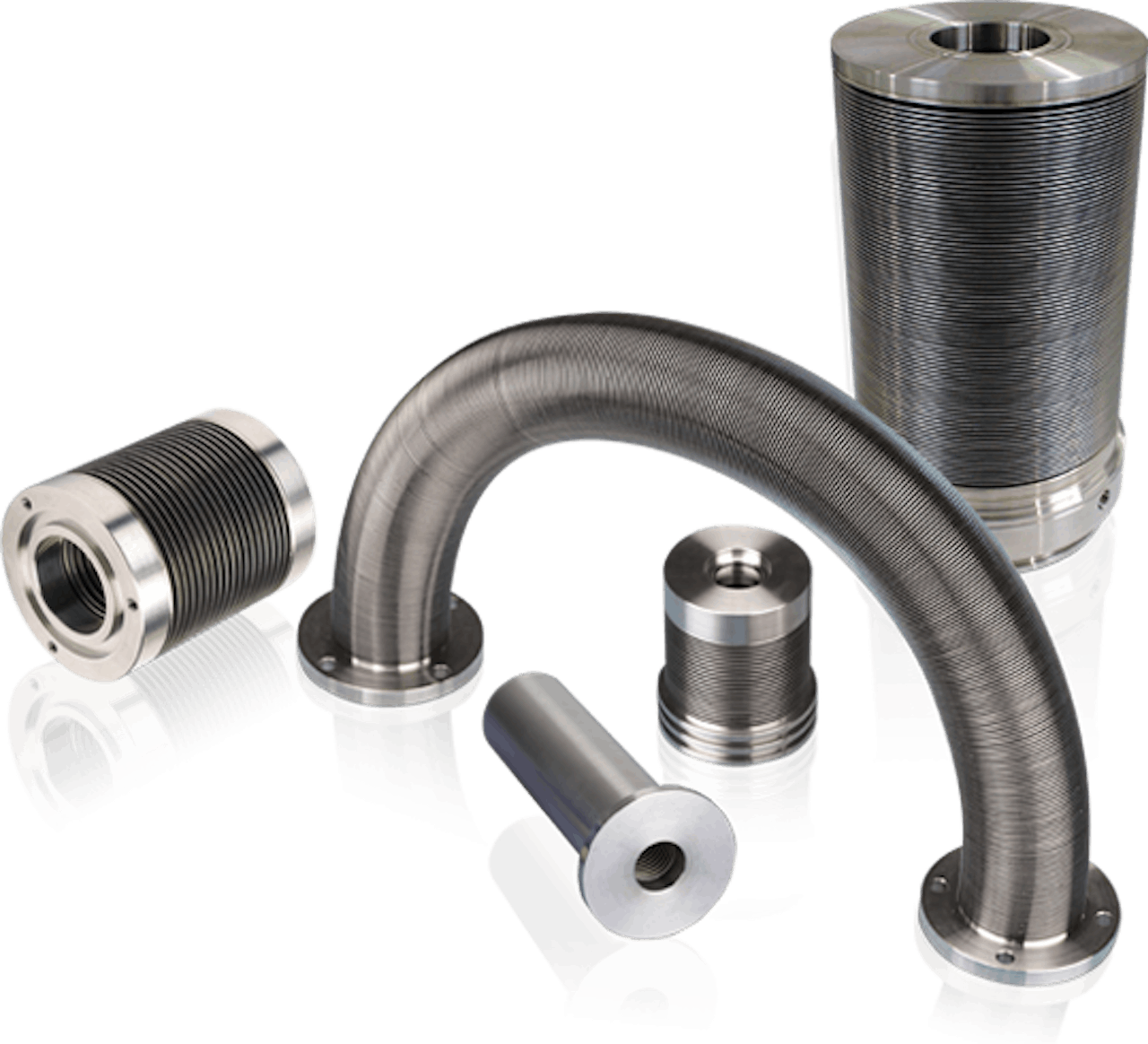

Bellows Valve

Bellows Valve / Bellows Seal Valve

Bellows valves or bellows seal valves are used to prevent leakage in piping systems. Bellows valves are important because they're often used in piping systems that transport potentially harmful liquids and gases. When designed and used properly, they reduce the risk of leakage and subsequent exposure chemicals and potentially harmful substances, allowing for improved safety of assemblies. Bellows valves are often used in sealing applications for aerospace, biotechnology, chemical processing, nuclear power, petroleum, pharmaceutical, and semiconductor.

MW Components manufacturers standard and custom metal bellows and metal bellows assemblies fit for a variety of applications and industries and will work with you to your designated specifications or in combination with your team to determine the right specifications for your application. To order custom bellows including bellows valves, request a quote.

Custom Manufacturing

Custom Bellows Valves / Bellows Seal Valves

MW Components custom manufactures bellows assemblies like bellows valves, expansion joints, aneroid bellows assemblies, volume compensator bellows, and atherm metal bellows assemblies designed to meet the unique functional needs and size requirements of our customers across multiple industries including aerospace, medical, semiconductor, high-performance automotive, and more.

We produce bellows and bellows assemblies using a variety of manufacturing methods and work with you to determine the best production method for your application and budget. Our bellows production facilities offer the highest quality manufacturing technology and state-of-the-art CNC machining, automation, welding, and other services. We also offer in-house testing to ensure peak performance and repeatability like helium leak testing, cycle testing, and pressure testing.

To work with our design and engineering experts to develop a custom bellows product specific to your needs, fill out and submit our custom bellows design form.

Bellows Valve Manufacturing

MW Components produces bellows valve assemblies using Hydroforming Technology. We work with a variety of materials and can produce multiple sizes, wall thicknesses, and added customizations. Below are typical ranges for our hydroformed metal bellows and assemblies.

Production Capabilities for Hydroformed Components:

- Size ranges from 1/4" I.D. to 48" I.D.

- Wall thickness ranges from 0.002" single-ply to 0.056" multi-ply

- Precision CNC machining within a few thousand of an inch

- Material options include stainless steel (300 series), Inconel®, Hastelloy®, titanium, copper, Monel™, brass, and phosphorus bronze

- DFAR-compliant materials available

For information about metal bellows outside of these ranges produced using other manufacturing processes including electrodeposited technology and edge-welded technology and to determine which may be right for your application, review this metal bellows comparison guide.

-

Advantages of Bellows Valves

Bellows valves have a number of advantages over other options, including:

- Precise temperature-dependent mechanical actuation without the need for programming or electricity

- Mechanically modulate heating and cooling systems

- Operate through billions of repeatable cycles without requiring recalibration

-

Optional Customizations for Bellows Valve

Our bellows valve assemblies are produced using precision hydroforming technology, which allows for multiple customizations. As an expert bellows manufacturer, we also offer a variety of non-standard manufacturing processes and customizations including the below.

- Multiple flange sizes in one assembly

- Customization to standard bellows valve available (holes, slots, etc.)

- Through-hole (clearance hole) and tapped-hole flange styles

- Custom end-configurations

Have a question or need a quote? Get in touch.

Our team includes engineers, manufacturing process professionals, and other experts who can help you get the part you need. Contact us today and we'll put you in touch with an expert who can help.