Ameriflex

Formed Metal Bellows & Bellows Assemblies

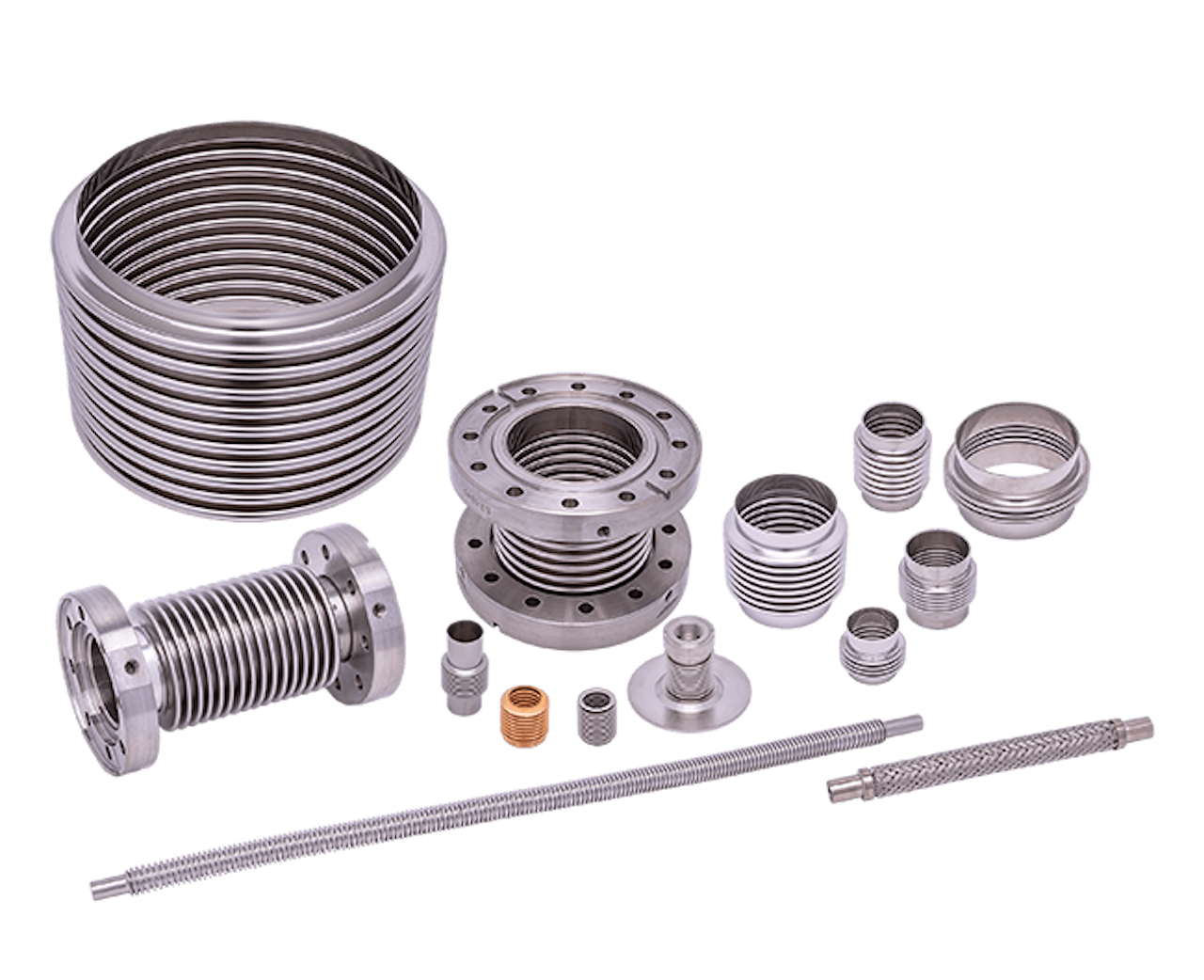

Ameriflex is proud to be recognized as a top manufacturer of formed metal bellows, metal bellows assemblies, and stainless steel braided hose. Since 1981, Ameriflex has served industries such as semiconductors, vacuum electronics, aerospace, lab and university, power generation, oil and gas, and more. With more than four decades of experience in the metal bellows industry, Ameriflex has built its reputation on quality, reliability, service, and expert technical knowledge. We also stock a large range of components for quick turn to meet your immediate needs.

Request a Quote

Work with our expert engineering staff to develop custom metal bellows and assemblies specific to your needs.

Formed Metal Bellows Manufacturer

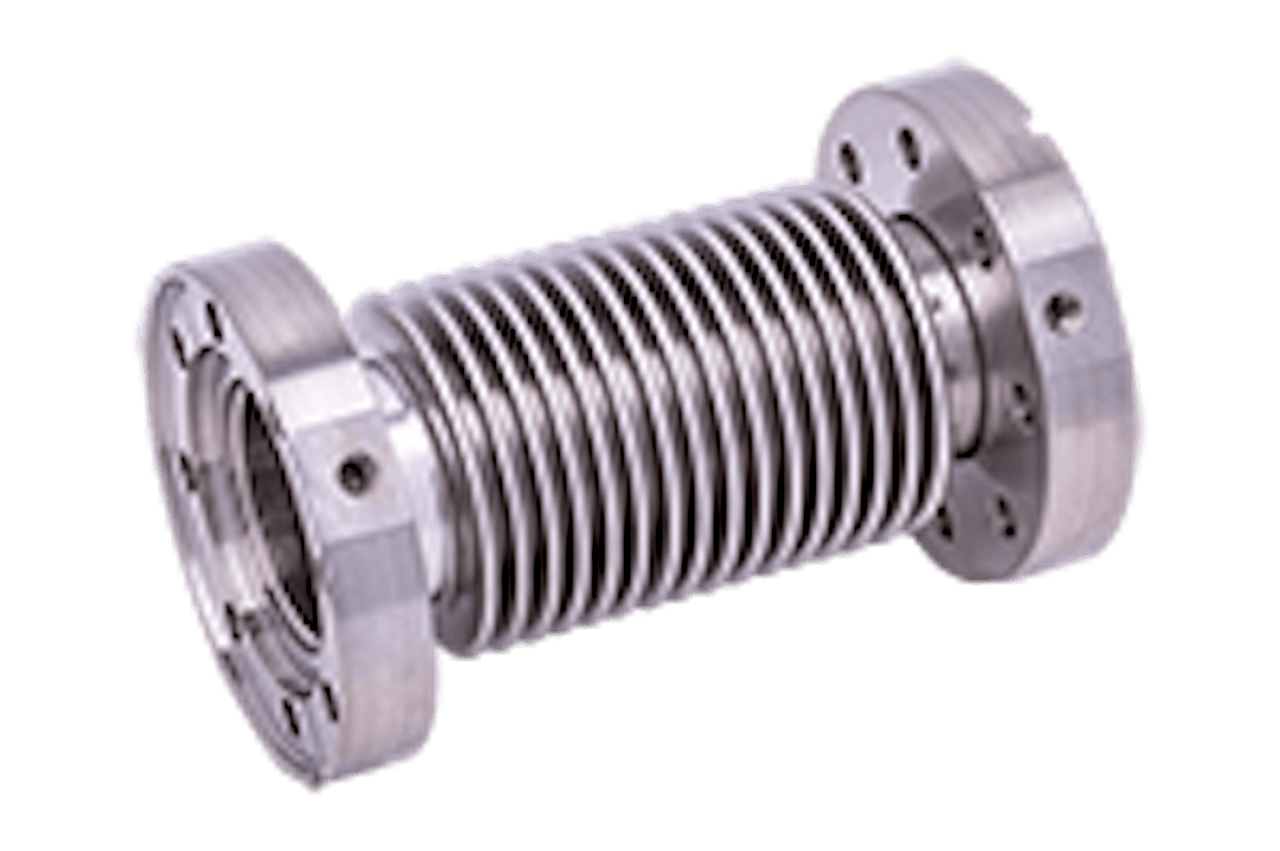

For over 40 years, Ameriflex has been a leader in the manufacturing of metal bellows for the vacuum electronics industry. Our bellows and expansion joints are designed to absorb and reduce vibration and relieve structural stress from pressurized environments, extreme temperatures, and other variables. We specialize in thin-wall bellows and offer prototyping as well as low-volume and high-volume production.

Our metal bellows are made to meet customer requirements for movement, pitch, bend radius, environmental conditions, and a variety of additional design considerations. Our expert engineering staff can design metal bellows to meet your needs, help with design issues or we can produce custom metal bellows to your specifications. With in-house tool-making capabilities, Ameriflex can create custom metal bellows that match your exact specifications.

We produce metal bellows in sizes ranging from 0.25” I.D. through 48” I.D., and wall thicknesses from 0.002” through 0.056” in either single-ply or multi-ply configurations. Our metal bellows are manufactured from several metals, including stainless steel, Inconel, Hastelloy, titanium, Monel, phosphorous bronze, copper, and brass. We also have a large stock of DFARS-compliant material on hand.

Our Products

-

Ameriflex produces metal bellows in ID sizes from 0.25" - 48”, and with wall thicknesses from 0.002” single-ply to 0.056” multi-ply. Our CNC machining capabilities enable us to maintain tolerances within a few thousandths of an inch. Request a quote today.

-

As a custom metal bellows manufacturer, we work with you to develop custom bellows assemblies for expansion joints, slip joint bellows, bellows valves, and more. Request a quote to get started.

-

We offer expansion joints in single or multi-ply varieties. Our expansion joints can be designed to absorb any combination of movements including angular, lateral, axial, or universal movements. Request a quote today.

-

Our bellows valves or bellows seal valves offer superior leakage protection in piping systems to ensure the safety of your assemblies. Request a quote today.

-

Our metal flanges are designed for years of non-stop service in severe working conditions for a variety of assemblies. We also produce C-rings and O-rings. For custom parts, request a quote.

-

We produce custom flexible braided hose including stainless steel braided hose for high-pressure and high-velocity applications. Materials include stainless steel, Inconel, and titanium. Request a custom quote.

Compliance, Quality & Certificates

At Ameriflex, we work directly with teams from a variety of industries to develop precisely the parts your application requires. From environmental conditions like high pressure, corrosion resistance, and extreme temperatures, to required leak rate, stroke, and sensitivity, no detail is too small. Our engineering team is well-acquainted with industry-specific requirements and is here to offer recommendations for strategic design to ensure that you get the right part, built to exactly the specifications your application requires.

We also have several certifications and compliance certificates, including the below.

Resources

Webinars, White Papers, Guides, and More

Request a Quote

We offer expert design support to ensure your bellows fit your application and use case. Contact us to learn more about our products and services or to request a quote for custom bellows manufacturing today.