Cold-Forming Technology

MW Components engineering and manufacturing experts use state-of-the-art machinery and up-to-date technology-driven processes to produce precise components for critical applications. One example of our process capabilities includes cold-forming, also referred to as cold-heading or roll-forming technology. Ideal for small metal parts manufacturing and other components, cold forming is a specialty process that can significantly improve outcomes for businesses in a variety of industries.

Cold-Forming Overview

Cold-forming or cold-heading is the application of force with a punch to a metal blank staged in a die.

The force exceeds the alloy’s elastic limit, causing plastic flow until the metal blank assumes the shape bound by the punch and the die. As the name implies, this method of metal part forming is achieved by force alone, forgoing the application of additional heat or cutting and shearing.

When machining a part, the grain flow of the material is interrupted as the original material is removed to form the part. Through the cold heading process, all original material is used causing a restructuring of the material grain as the part is formed. This results in improved tensile strength as compared to manufacturing techniques.

Check Out This Video on the Heading Process

Open Die Cold Forming

Cold forming creates favorable strain (work) hardening. With open die cold forming, the metal is placed between two flat dies and compressed until the shape is revealed. MW produces cold formed bolts and cold formed nuts as well as other products using this technology. Our proficiency in open die cold formed fasteners allows us to provide answers to complex needs, including solutions for difficult spaces and innovative applications.

Open Die Cold Forming Capabilities

- Long length, small diameter fasteners

- Exceptional straightness in long parts

- Straight, long parts in high volumes

- Complete automation for accuracy and repeatability at lower costs

- Cost reduction by replacing high-cost machining and multiple parts

Typical Applications

Many types of parts can be produced using cold-heading technology, including fasteners, screws, nuts, bolts, electrical contacts, and rivets. This manufacturing process is ideal for small metal parts, including micro electronic components, micro contacts, micro grommets, glass and metal seal manufacturing, and other small component manufacturing.

Additionally, the following project types generally benefit from cold-headed / cold-forming manufacturing:

- Mission-critical applications

- High volume requirements

- Correction of part failures

- High material strength requirements

- Tight tolerances and critical specs

Many shapes and part configurations can be produced using cold-heading technology-- some examples include threads, knurls, heads, chamfers, grooves, tapers, and undercuts.

Required features which cannot be produced through standard cold-heading processes can be achieved by utilizing secondary procedures such as rolling, threading, pointing, bending, or annealing.

Why Use Cold Forming?

One of the biggest advantages of cold forming is cost savings. Cold forming is a net (or near-net) shape solution. During the process, wire is transformed by a sequence of die blows into a specific shape, with the material flowing to fill the part geometry and dimensional tolerances defined by the tooling. So there is virtually no waste created. Without scrap to deal with, there is little to no recycling cost associated with the process, less lubricant to reclaim, and minimal labor to handle it all. In general, the wire raw material is less expensive than the bar stock used for machining.

With all forms of screw machining, including single- and multi-spindle and Escomatic processes, scrap is not only unavoidable, it is a significant by-product of the process, often equivalent to 50% of the final part’s mass.

With an optimized part formation progression for a complex component, cold heading delivers yields at an average rate of 70-120 parts/minute (PPM) and can be up to 350 PPM in for some part designs. Generally, yields for a similar design produced from a multi-spindle screw machine will be in the 6 – 20 PPM range, an order of magnitude faster for cold forming. This faster yield ultimately reduces cost and speeds up product delivery for component and small metal part manufacturing.

Not only does cold forming allow for parts to be manufactured quickly, but also accurately and consistently. Critical and close tolerances can still be achieved in high volumes over time versus more expensive machining processes. Additionally, these tolerances are maintained consistently throughout the production process making sure that every piece follows the project's design spec from start to finish.

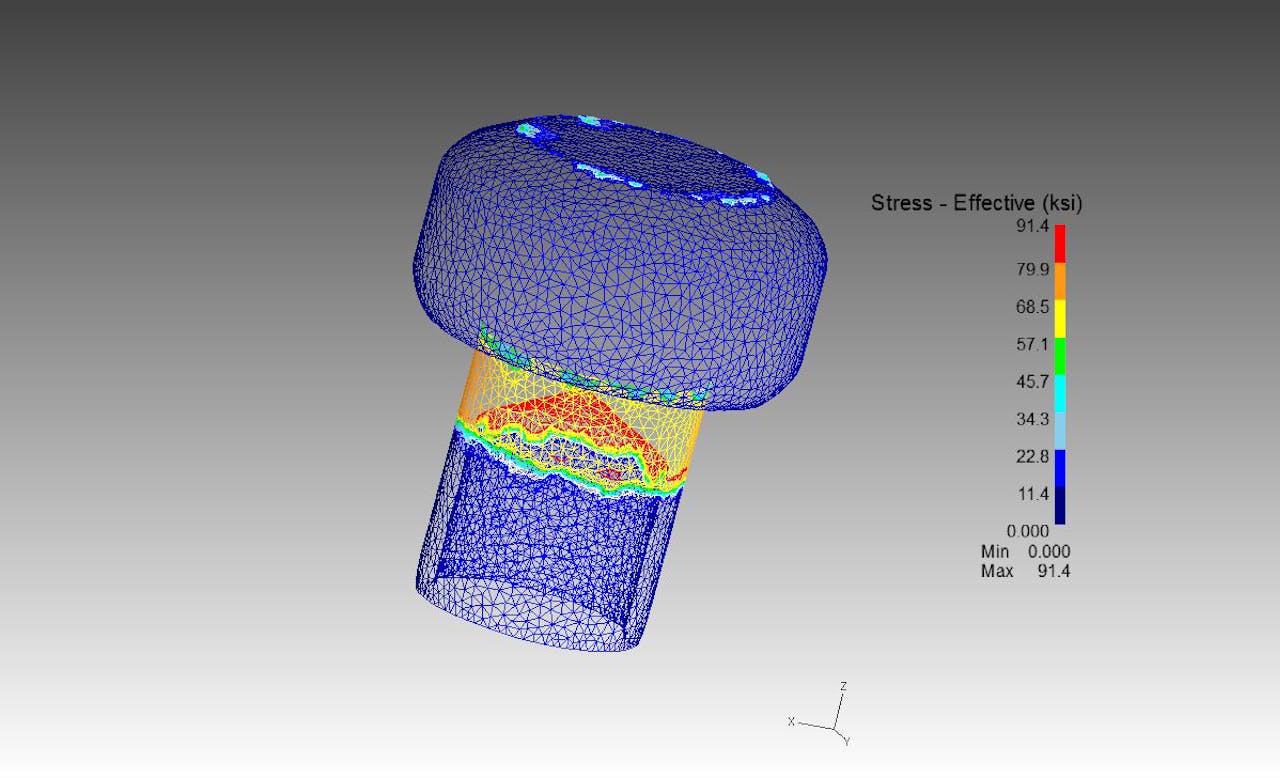

Cold forming is a process in which the native tensile strength of the material is increased through work hardening. Here’s how it works: For every 1% of area reduction or increased surface area of a part’s cross-section due to cold forming, its tensile strength increases by a factor of ~0.6-1.5 depending on the alloy. This physical property is known as the work hardening rate of the material. The work hardening rate varies depending on starting tensile strength and material composition.

No process that removes material from the native shape, such as screw machining, can achieve this.

Because cold forming produces virtually no metal scrap, it requires less reprocessing, along with its associated costs of transportation, fuel, and labor. Lubricant is used in the die formation process but at a fraction of the rate for a screw machine (cutting) operation.

For screw machine operation, materials often contain free machining additives. These free machining additives are added directly to the molten metal before casting into ingots. They are not soluble in the alloy composition and form discrete particles of various shapes and sizes in the ingot casting.

Cold forming does not require these additives. From an engineering perspective, because the raw material has fewer inclusions, a cold-formed part lends itself to a superior potential design.

Cold-Formed Product Brochure

If you are interested in learning more, view our Cold Forming Product Brochure for information on cold-formed products like micro electronic components, micro contacts, micro rivets, micro grommets, Kovar pins, and more or contact us for a custom quote.