Products > Spring Energizer Products

Spring Energizer Welded Components

Laser welded spring energizer components help overcome the load constraints of a polymer seal jacket and minimize the change of seal failures through a high-quality spring weld. Laser welded spring energizers ensure seal integrity using a precise weld that provides evenly distributed support for the load.

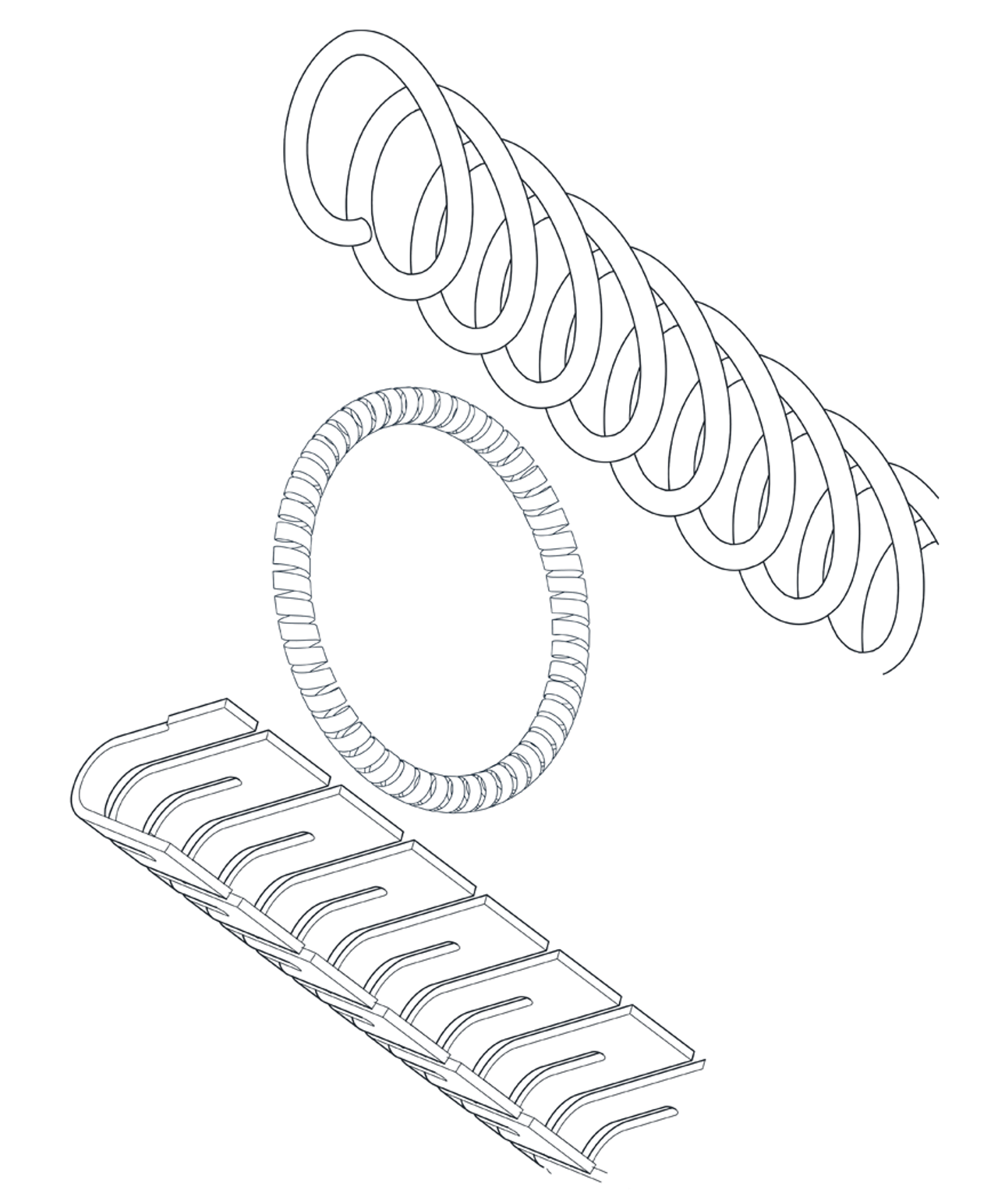

Our laser welded spring energizer products include V-springs, U-springs, Helical springs, and Canted coil springs. For in-depth information on our laser welding services and products, visit our laser welding page.

For details on spring load and deflection for our spring energizer products, visit our information page here.

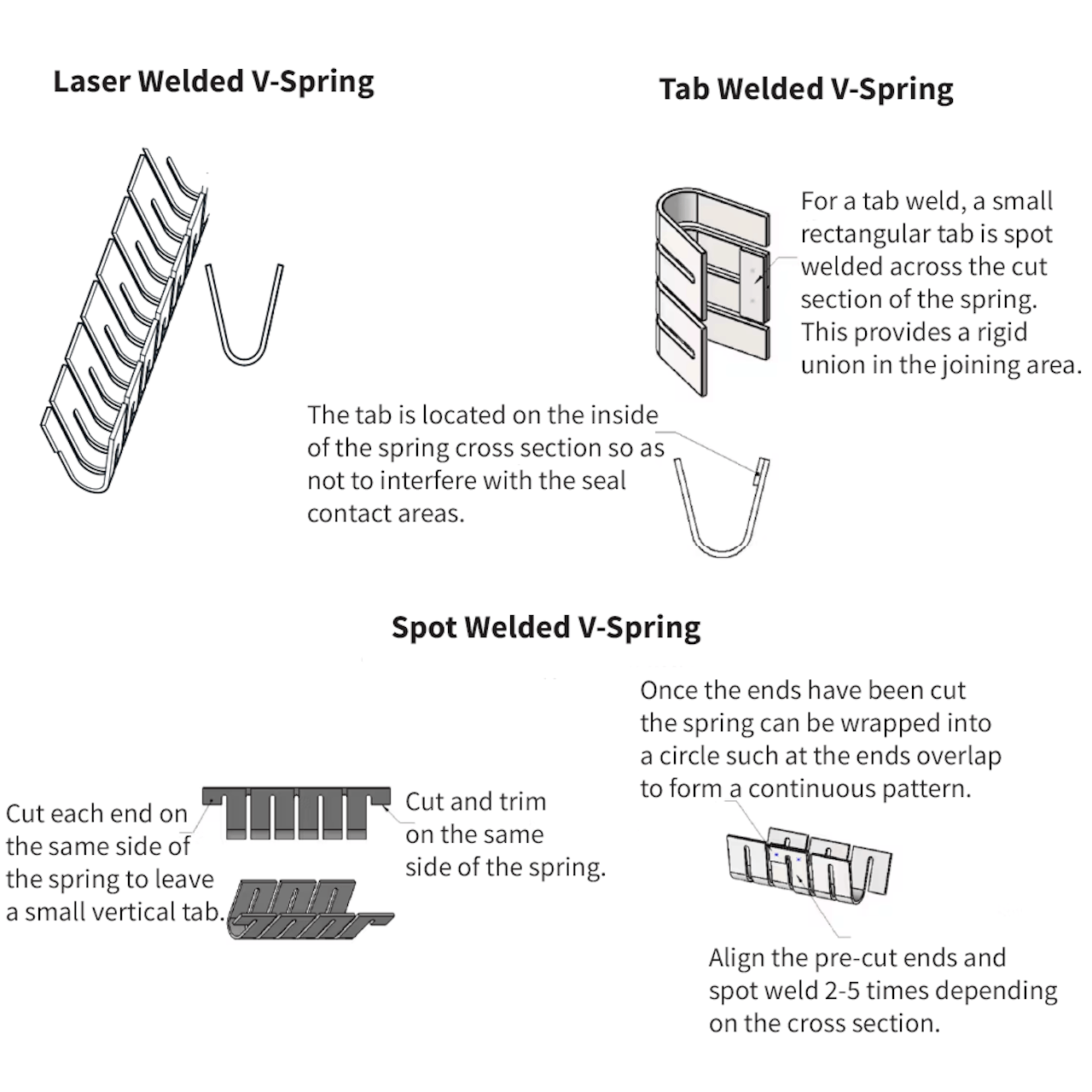

Laser Welded V Springs

Also known as meander V-springs and punch finger springs, laser welded V-springs have a v-shaped pattern. They are made from Elgiloy or stainless steel and produce an even, linear load over a large deflection range. V springs work for static and slow to moderate dynamic motion applications.

Our V-springs are available in continuous lengths starting at 100 ft. Annual quantities over 100,00 ft are available, as are pre-cut and welded V-springs.

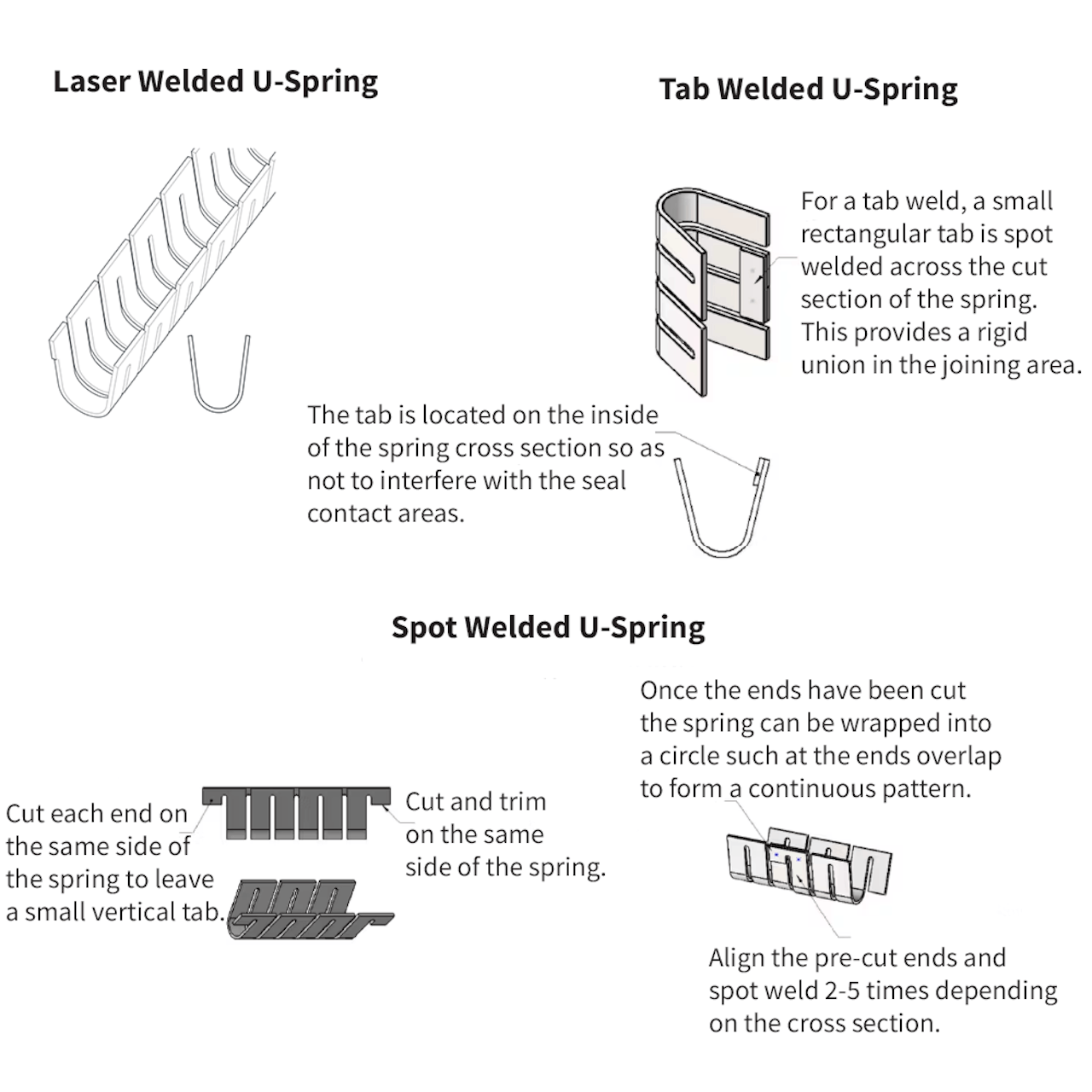

Laser Welded U Springs

Also called meander U-springs or cantilever U-springs, our U-spring energizers provide clamping forces using a u-shaped pattern. The pattern allows a low spring load to be applied over a large deflection range.

MW's Maudlin location stocks several sizes of u springs in Eligloy and 301 stainless steel, although custom manufacturing is available for other materials. Stock springs are available in continuous lengths starting at 100 ft. Annual quantities of 100,000 ft or more are available.

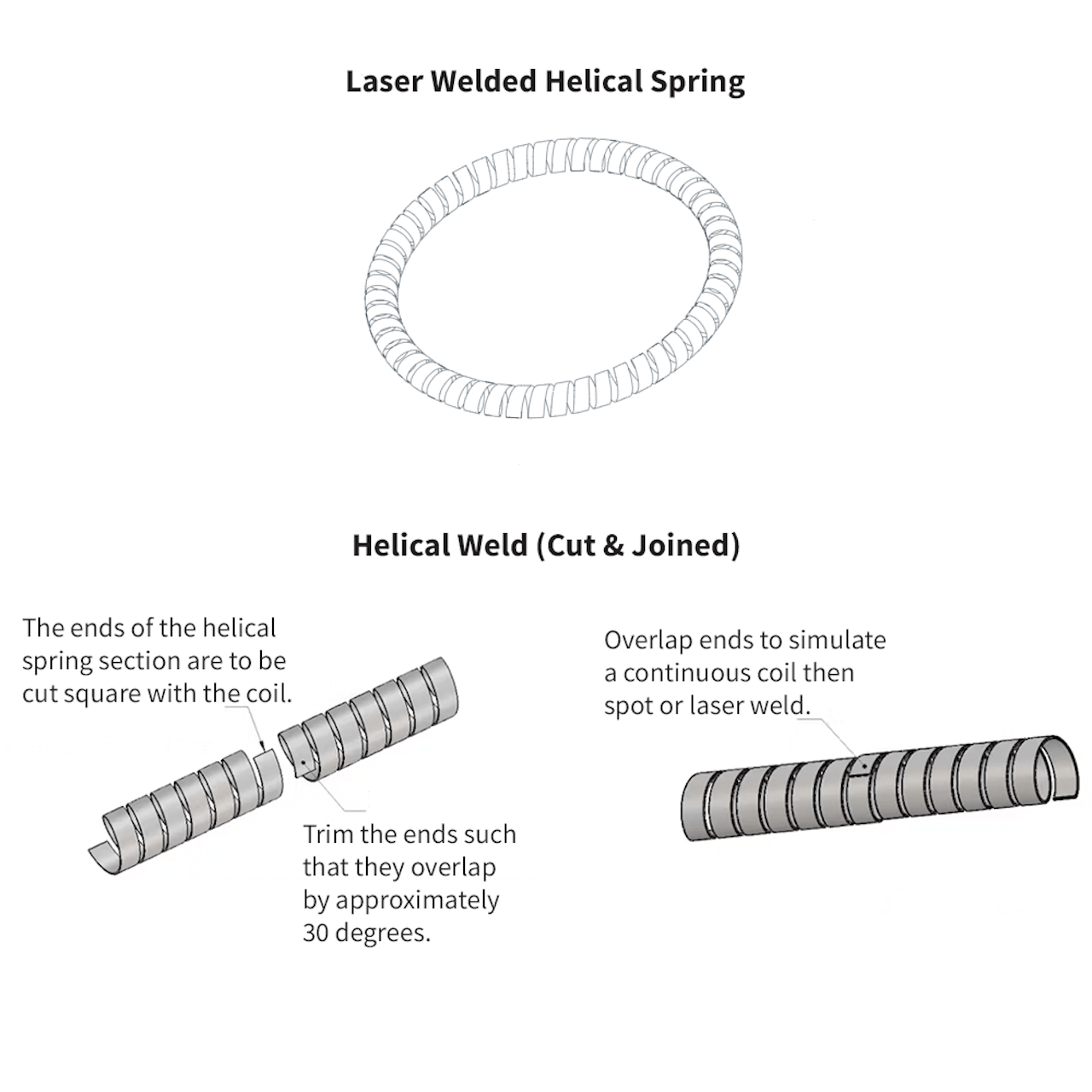

Laser Welded Helical Springs

Laser welded helical springs produce high loads. Unlike many of our other spring energizers, laser welded helical springs are typically used over a smaller deflection range, which makes them ideal for a variety of applications including spring replacement for o-ring loaded u-cup seals.

Our helical springs are available in stainless steel or Elgiloy, with lengths up to 10 feet. To reduce lead time and cost for customers, our Maudlin location has seven standard thicknesses of Eligloy in stock. We can supply helical springs or one pound coils of raw material that you can use to roll helical springs at your location.

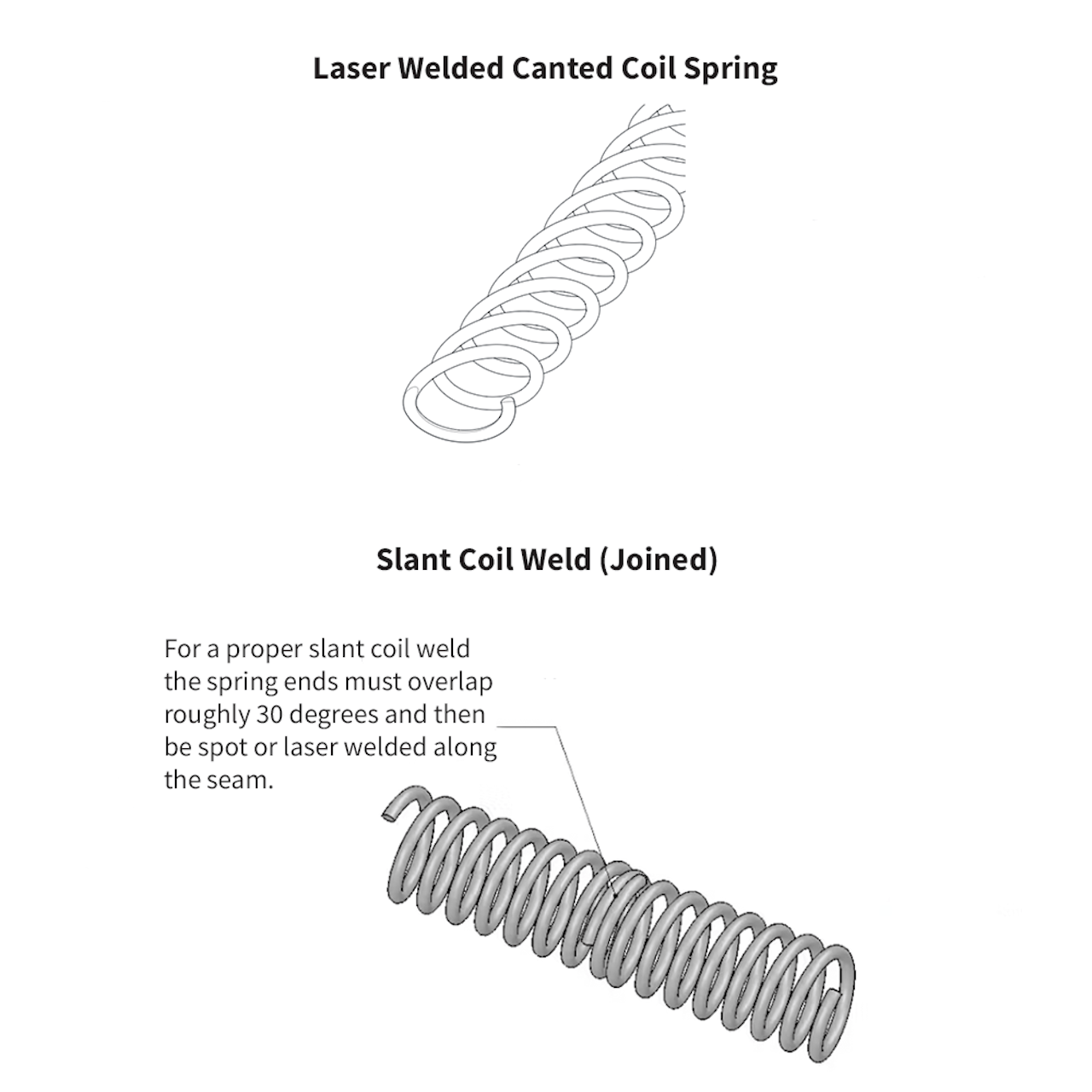

Laser Welded Canted Coil Springs

Laser welded canted coil springs are known by a variety of terms, including slant springs, wire wound seal springs, and more. They allow for continuous, predictable loads over a wide deflection range and have nearly zero compression set. In most cases, canted coil springs are manufactured from 302 or 316 stainless steel, although other materials are available upon request.

Canted coil springs are available with cross sections between 000 and 400 and can support light, medium, and high load applications. Lead times are 3 weeks or less for standard materials and 6-8 weeks for specialty alloys.

Our Manufacturing Locations

Have Questions?

As the leading producer of laser welded spring energizers in the industry, we have years of experience working with difficult questions and challenging applications. For expert support, send your question our way and we'll make sure it gets to the engineer or manufacturing profession who is best qualified to help.