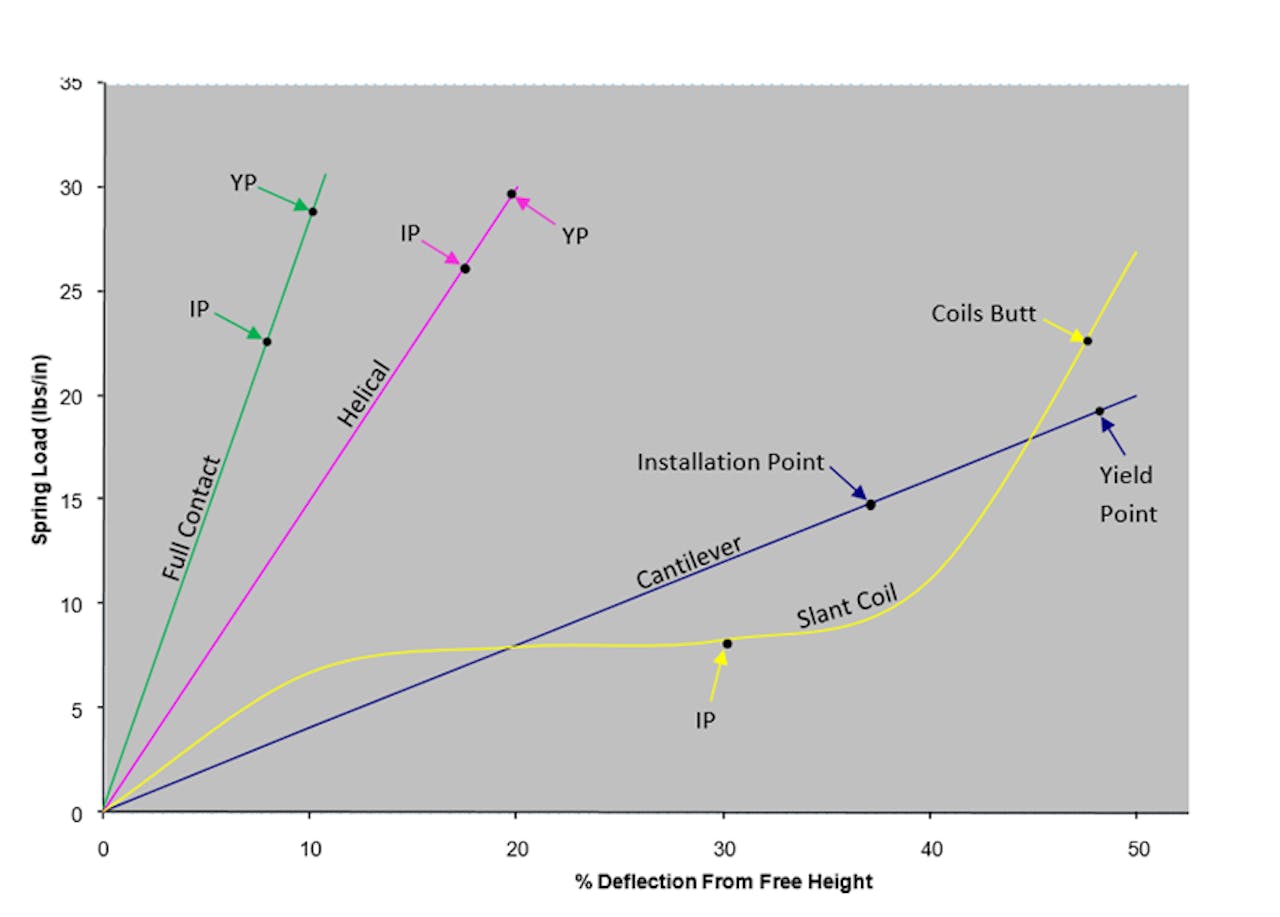

Spring Load vs Deflection for Spring Energizers

Understanding the characteristics of the spring in the spring energized seal or connector mechanism is important when you are designing an engineered solution. Too much spring force can lead to premature wear or assembly/disassembly problems. Whereas too little force can lead to seal leakage or lack of contact in an electrical connector. MW Components can help navigate these difficult waters and guide you to the perfect spring solution.

It all starts with the load vs. deflection curves of each spring. The graph below shows some of the more common spring curves in relation to each other. These curves do not represent any particular spring but instead are shown for comparison purposes.

Types of Spring Energizers

If we look at each curve we can pick out a few attributes that will help us choose the right spring for a given application.

- Full Contact – This is a very steep curve meaning high loads are achievable with little deflection. This is a good spring to use in cryogenic applications but due to its construction Full Contact spring can only be used in face seal configurations.

- Helical – This is another high load spring but with more deflection available it can be used in a wider range of applications. It is available in axial or radial configurations for low pressure, low temperature, and/or light gas applications.

- Cantilever – Cantilever spring is a good starting point for many spring energized seal applications. Its large deflection range, medium load characteristic and availability in many different materials make it great for slow to medium speed dynamic applications as well as difficult combinations of pressure and temperature.

- Slant Coil – This spring is very unique in the MW Components family of springs. Its curve shape is not linear like the others but instead has a flat section over a wide range of deflection. What this means is that as the seal jacket wears, the spring force remains constant. Slant Coil spring is also used in mechanical and electrical connectors. Its wide deflection range and constant force make it the ideal spring for those applications requiring closely controlled contact forces.

Though there are times when more than one type of spring can solve the problem, it is important to understand the differences when beginning the design process. Starting with a spring better suited to the application will help speed up the process saving time and money during development.

Visit our spring products page for a complete list of the available springs, load curves, and materials.