Laser Welding

Laser welding is useful in a variety of situations and product applications. One of the most useful is for welding spring energizers. Our Maudlin location laser welds V springs, U springs, helical springs, and canted spring energizer products. Contact Maudlin for more information.

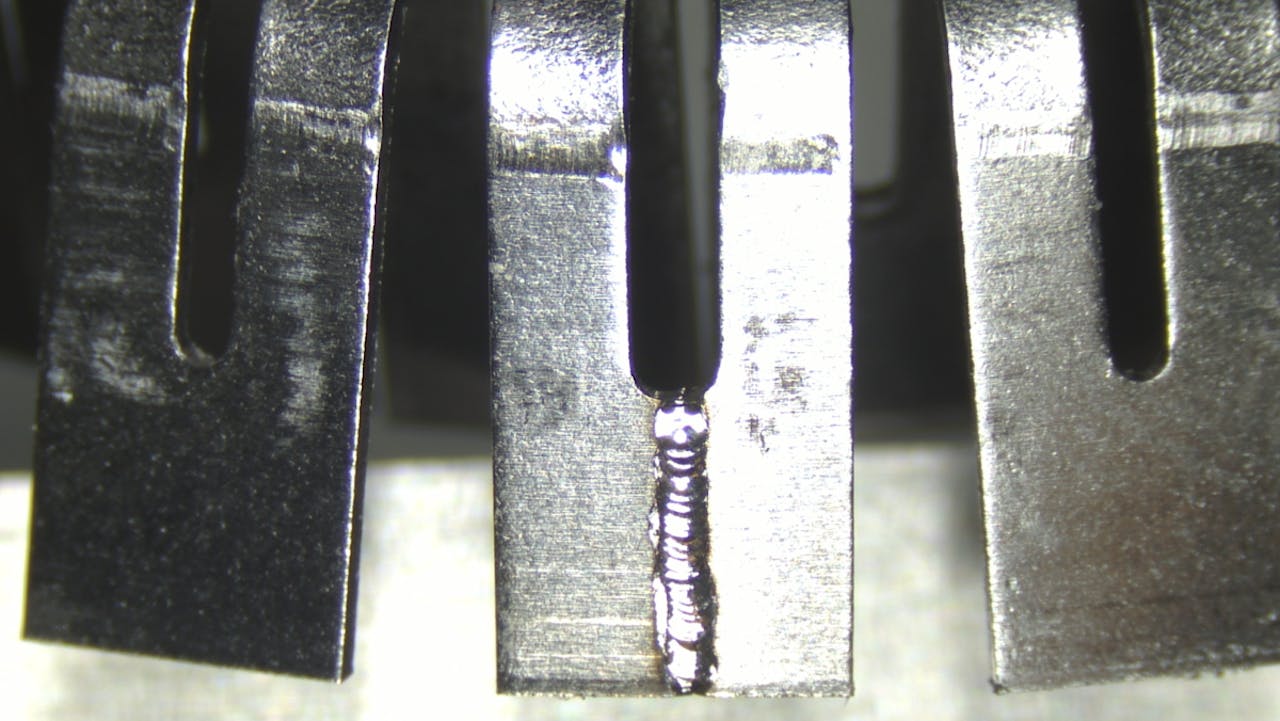

Through many years in the business, we've found that one of the most common contributors to seal failures is an improper or missing energizer spring weld.

An improper weld can lead to a "high point" on the sealing lip which causes uneven pressure, leading to premature wear and part failure. When a spring weld is missing, the spring cannot provide adequate evenly distributed support, leading to support gaps and possible part failure. Laser welding creates a precise weld, allowing for even distribution of load to ensure proper sealing.

Advantages of Spring Laser Welding or Cut and Weld

There are several advantages of laser welding, including precise and even weld joints which make it ideal for small components. Some of the many benefits are listed here.

Weld Configurations

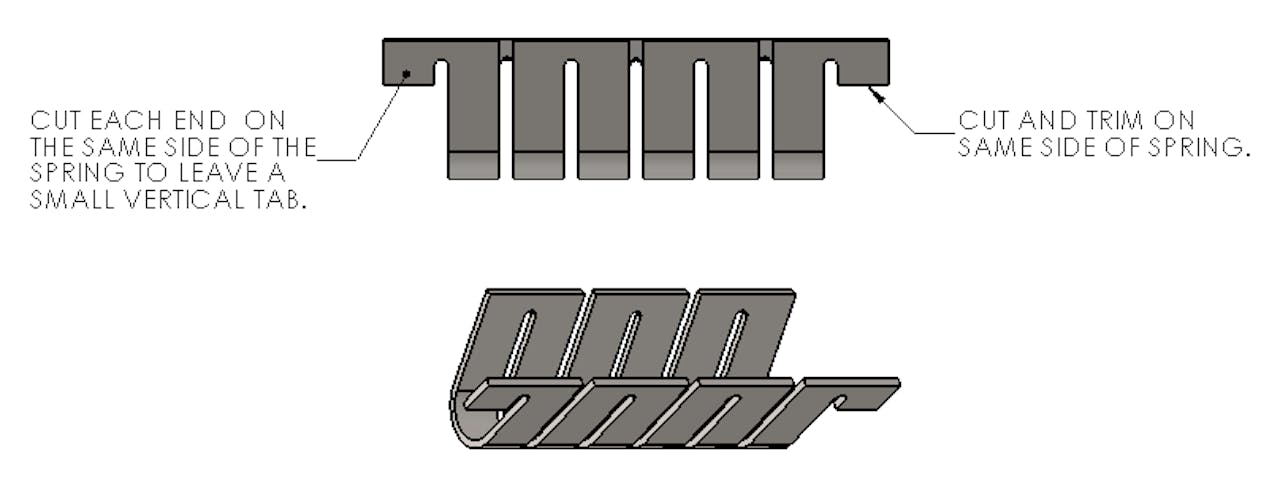

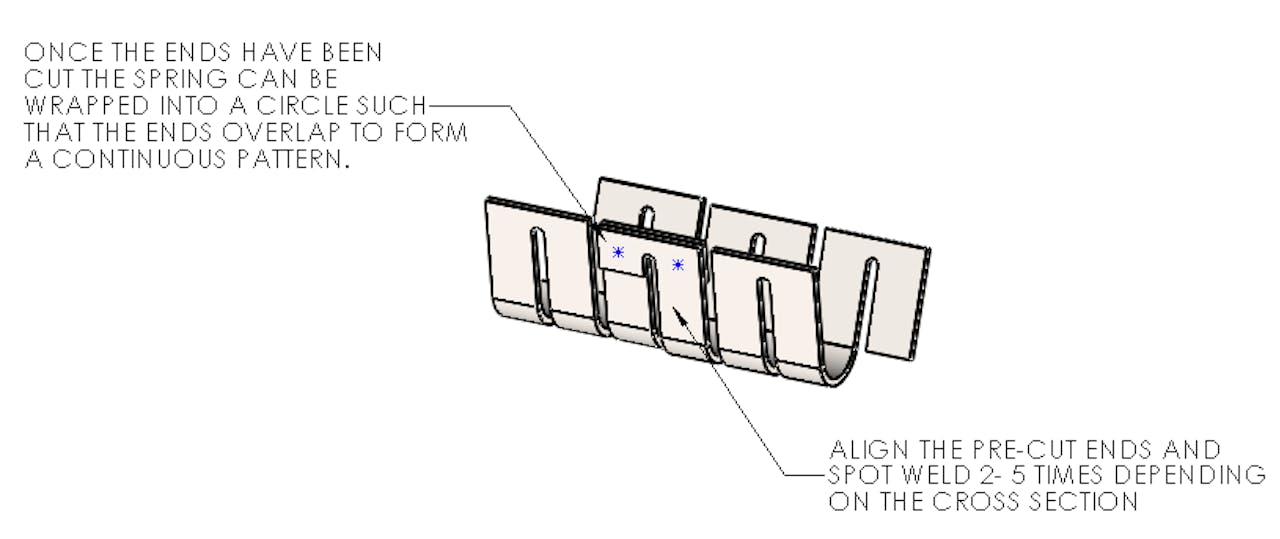

Cantilever Spot Weld (Cut & Joined)

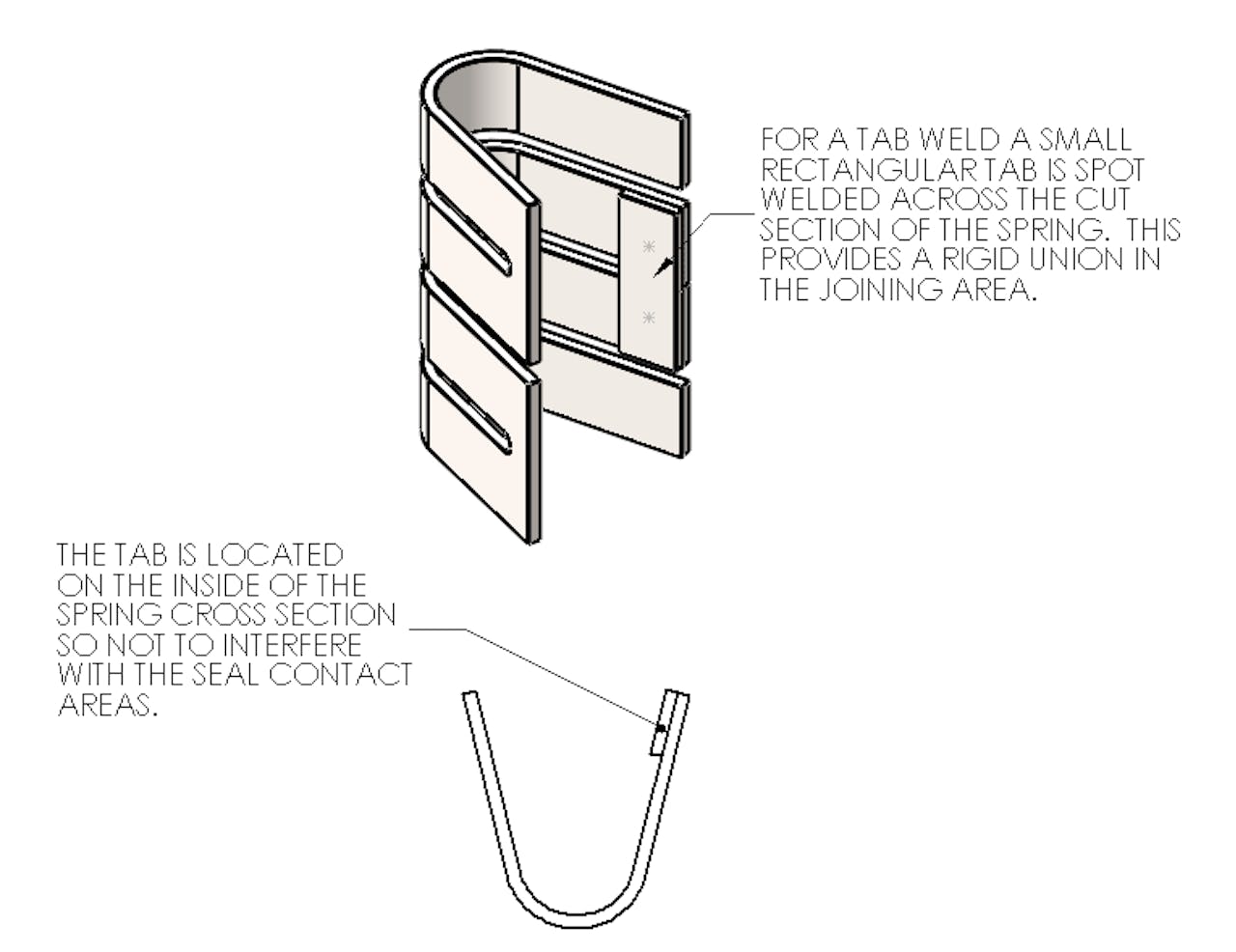

Cantilever Tab Weld

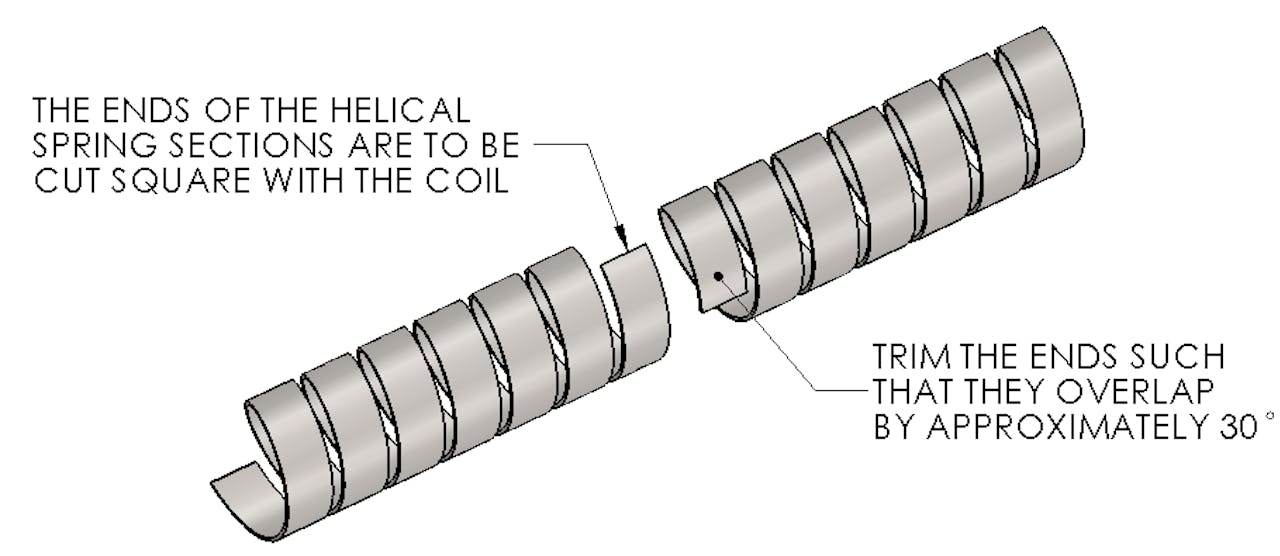

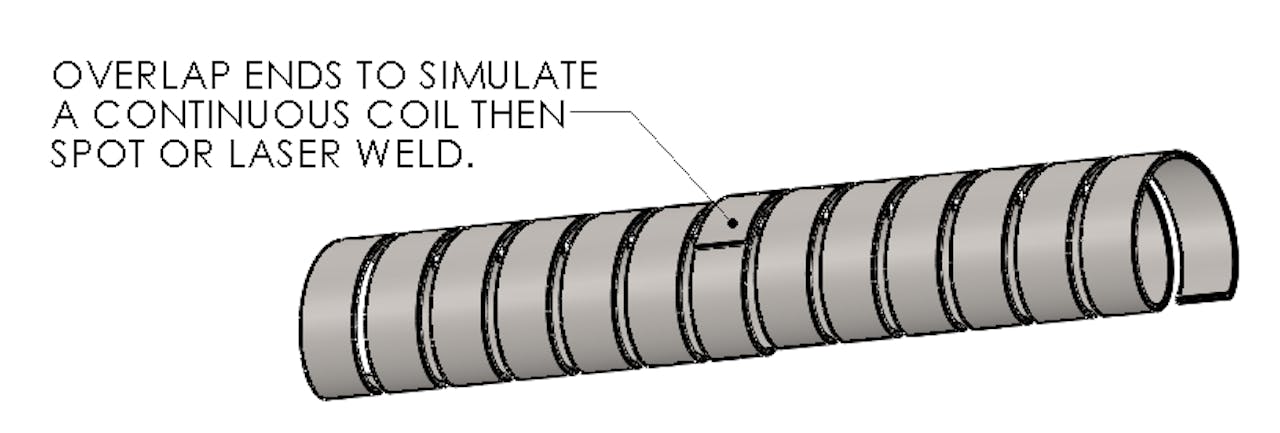

Helical Weld (Cut & Joined)

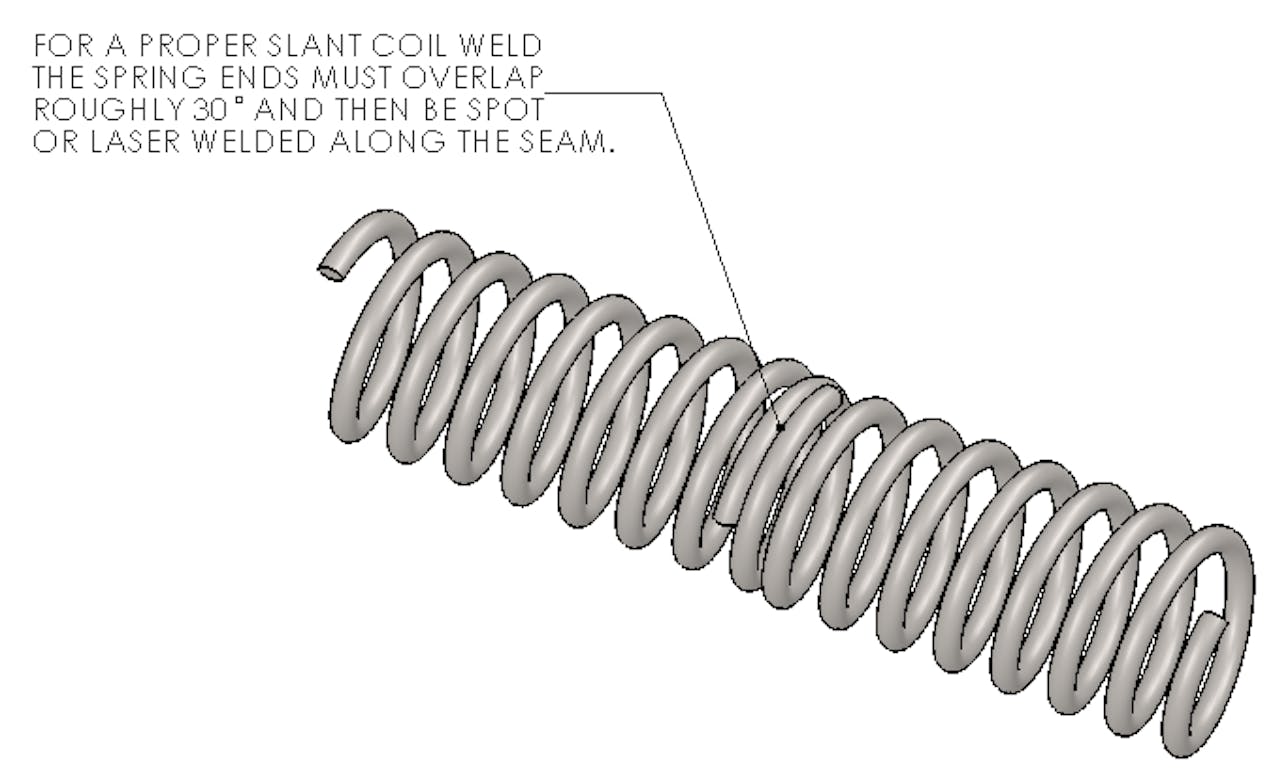

Slant Coil Weld (Joined)

Applications

Laser welding is recommended for slant coil springs, helical springs, and cantilever springs; however, it can also be used in a variety of other applications.

Industries Served

This manufacturing service is applicable to a variety of industries. Some of the industries we work with are listed below.