Products > Bellows / Couplings

Vacuum Bellows

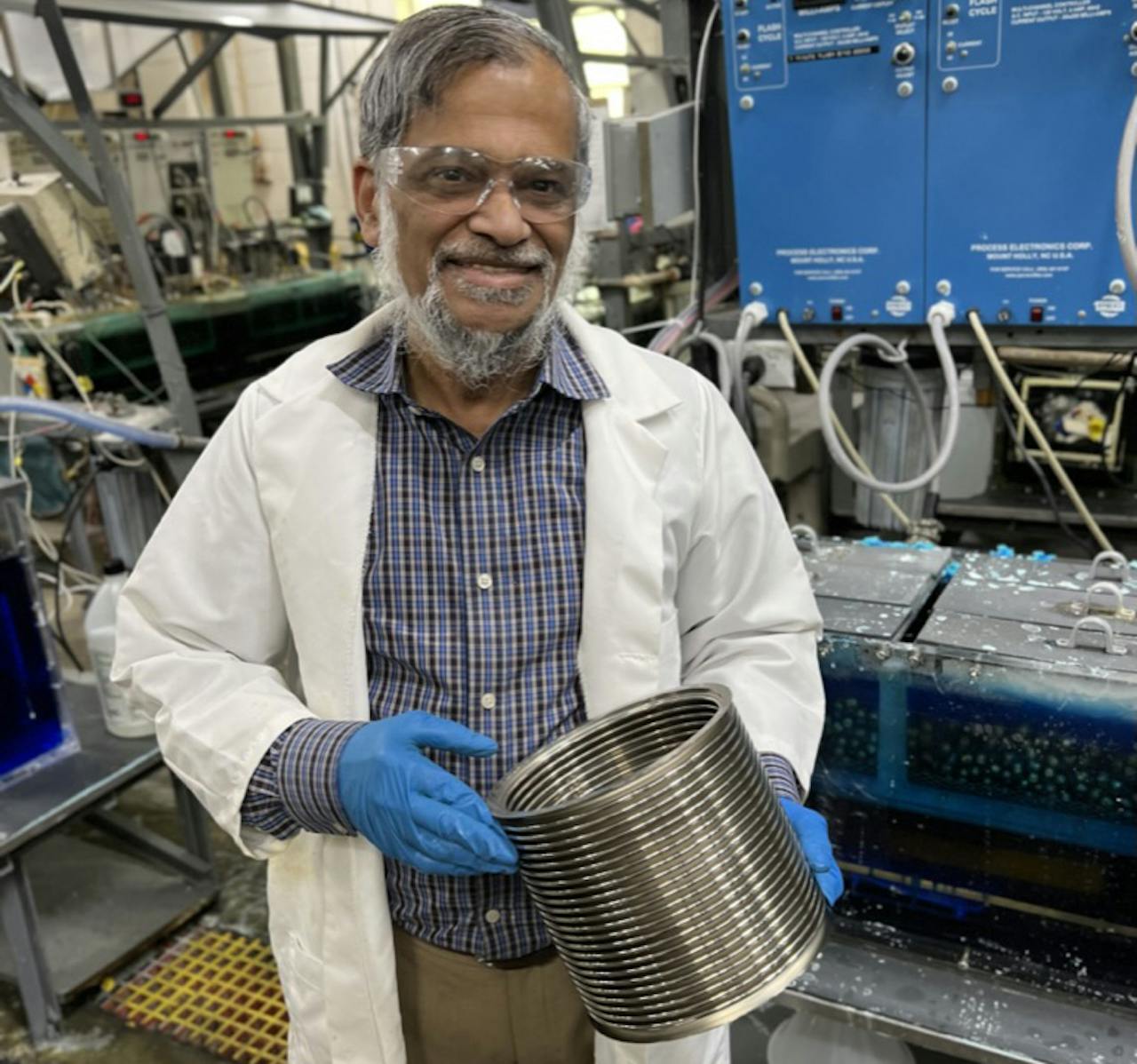

MW Components' three metal bellows manufacturing facilities (Servometer, Ameriflex, and BellowsTech) produce a full line of metal bellows and bellows assemblies, including vacuum bellows for a variety of industries—from aerospace and defense to high-vacuum applications. Our metal bellows are produced using three unique technologies—electrodeposition, hydroforming, and edge-welding. As a leader in the metal bellows manufacturing space, our engineering experts will gladly work with your team to determine the appropriate production method for metal bellows, while taking into consideration your application requirements, necessary specifications, timeline, and budget.

MW Components combines high-quality manufacturing and decades of industry experience with dedication to quality control. Our bellows production facilities offer a variety of quality certifications, including ISO 9001, AS9100D, and Nadcap: welding, in addition to standard and specialty testing, including healium leak detection and various performance tests to ensure the longevity and integrity of your assemblies.

CUSTOM MANUFACTURING

Custom Vacuum Bellows

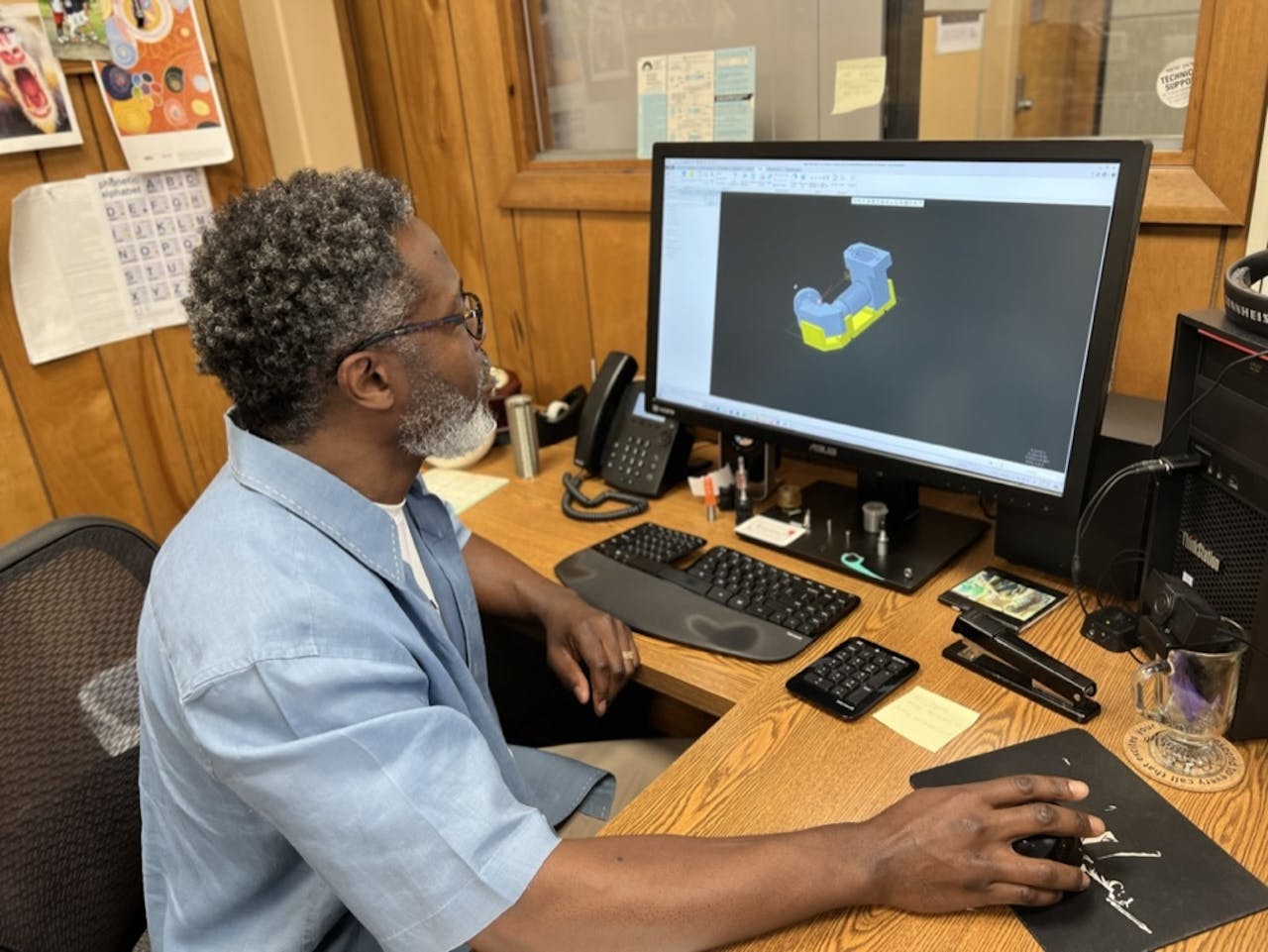

Our engineering and manufacturing experts work with your team to develop precisely the vacuum bellows and assemblies your application requires, making recommendations for processes, materials, testing, and more. In addition to our variety of metal bellows production techniques and extensive design and engineering support, MW Components facilities offer many options for custom metal bellows, including specialty materials, configurations, and end-fittings. We manufacture bellows assemblies with a wide variety of standard flanges (CF or Conflat Bellows, KF, ISO, and NW), custom flanges and fittings, and produce bellows assembly components including, valve assemblies, slip joint bellows, and expansion joints.

Our bellows assemblies are either built to meet customer specifications or designed by our team of in-house engineers to meet your unique requirements. Our years of manufacturing experience and CNC machining capabilities help us create vacuum fittings with the perfect combination of diameter, length, and wall thickness to tolerances within a few thousandths of an inch. We also perform helium leak testing to ensure the integrity and defect-free construction of assemblies, making them ready for immediate installation, which saves you time and money. To ensure peak performance, we manufacture our bellows assemblies from the highest quality domestically sourced or DFAR-compliant materials, including stainless steel and other specialty materials, which helps ensure the quality and longevity of your components.

Request a quote to send us your specs or configure a part.

Vacuum Bellows Manufacturing

MW Components combines exceptional engineering, state-of-the-art manufacturing, extremely close dimensional tolerances, and decades of experience to deliver top-quality vacuum bellows for any use case.

We use three distinct manufacturing processes for metal bellows: edge-welding, hydroforming, and electroforming. Each production process has its benefits and recommended specification ranges. For more information on achievable tolerances for each production method, review our Metal Bellows Comparision Guide. Or request a custom quote, and our team of experts will make a recommendation on which process should be used to achieve your design specifications

Production Capabilities for Vacuum Bellows Components:

- OD Size ranges from 0.020" to 43" (tooled) or 50" (not tooled)

- Wall thickness ranges from 0.0002" to 0.056"

- Max convolution length up to 200" (varies by ID size, material, and wall thickness)

- Precision CNC machining within a few thousand of an inch

- Typical materials: stainless steel (300 series), Inconel®, Hastelloy®, titanium, copper, brass, phosphorus bronze, Monel®, and FlexNickel®

- DFAR-compliant materials available

Applications

Metal bellows are used in vacuum systems and other high-pressure applications to separate environments, contain pressure, and provide axial movement to assemblies. They are often found in hydraulic applications or as compensators in devices or pipelines. Our vacuum bellows are created to your exact specifications to fit your requirements for sensitivity, leak rate, max pressure, temperature exposure, life cycle, and more.

MW Components manufactures standard and custom metal bellows and flexible metal hose for a variety of applications and industries. Some of the more common applications include aerospace, medical, semiconductor, defense, and cryogenics. Our commitment to quality and precision manufacturing enables us to meet the extremely high standards of each of these industries and their unique applications.

-

Our metal bellows and flexible metal hose are found in fuel line pumps of commercial space transport crafts and on NASA's Curiosity Mars rover as well as various military aircraft.

-

MW Components provides high-quality, high-precision manufacturing for semiconductor OEMs and distributors. As an example, our metal bellows are used in valve applications within chip manufacturing equipment.

-

MW Components' metal bellows and flexible braided hose are used to help regulate temperature and pressure in liquid nitrogen and oxygen tanks, gas pumps, and various other cryogenic applications.

-

Leading labs and universities like Brookhaven National Lab and Argonne National Laboratory turn to us to deliver components that match their exact specifications, from alternative energy research to particle beam science and beyond.