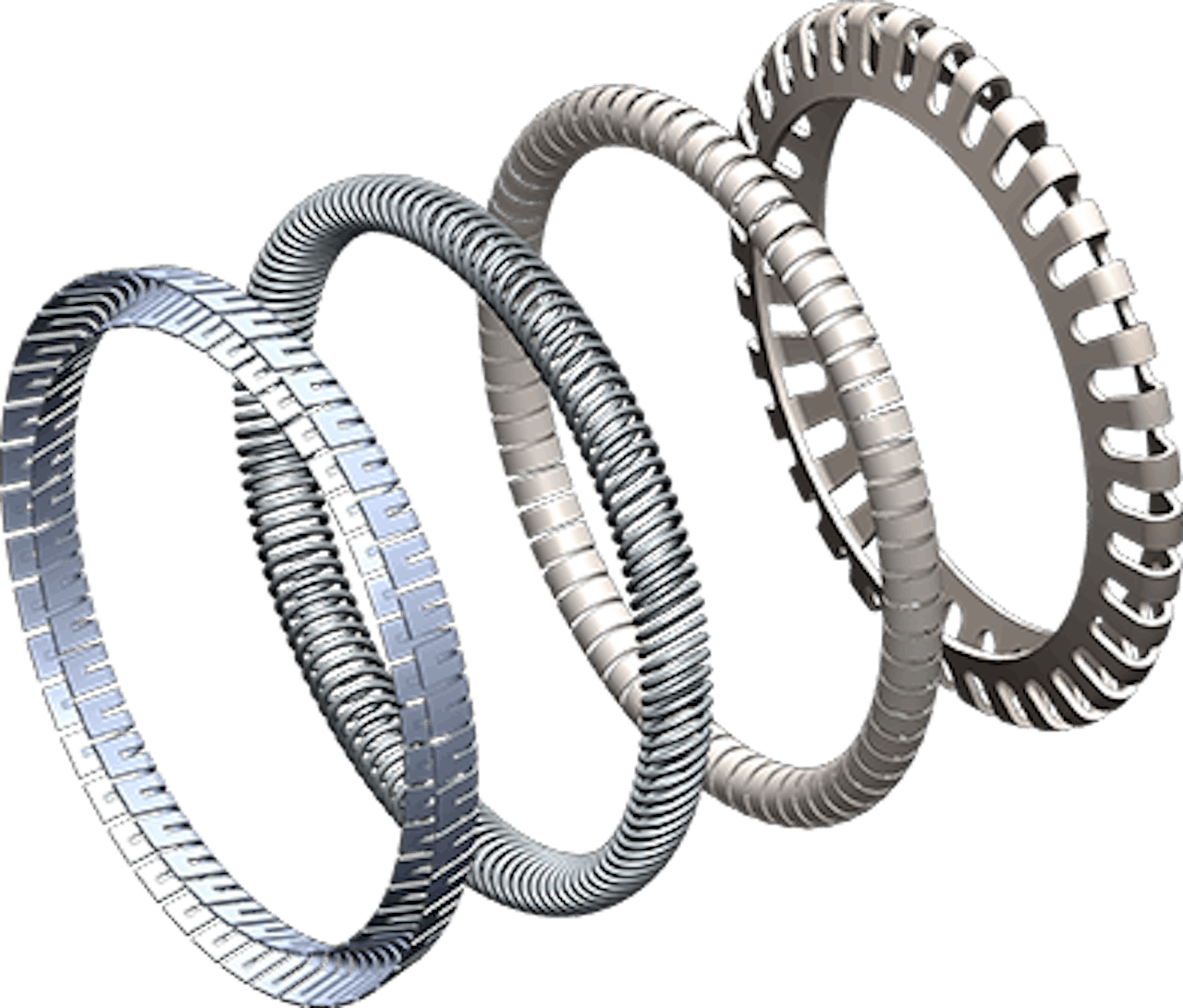

Spring Energizer Alloys

Spring Energizer Alloys, Features, and Availability

A unique factor of MW's spring energizers aside from their load characteristics is that they are available in a multitude of materials. These materials include everything from basic 300 series stainless steels to exotic alloys like Hastelloy®, Inconel®, and Elgiloy®. Each one having unique properties making them favorable for a wide range of applications. Below is a list of our more common materials and a brief description of where each might be used.

Spring Energizer Materials

- Elgiloy® – Elgiloy® is one of the best all-around spring materials available. It is NACE-approved, has excellent mechanical properties even above 500 °F, and is the material of choice for a majority of oil and gas applications. Because of its broad range of use, Maudlin has made it a point to purchase Elgiloy® in large quantities. In fact, Maudlin is one of the largest raw material buyers of Elgiloy® in the world. Because of these volumes, Maudlin has some of the best pricing on Elgiloy® spring anywhere. If your application requires the very best, Maudlin has it and at a great price.

- 300 Series Stainless Steel – For use in general services covering a wide range of fluids up to 550 °F. For corrosive environments, the maximum service temperature should not exceed 400 °F. Available alloys include 301, 302, 304, and 316.

- 17-7 PH Stainless Steel – Similar to the 300 series stainless steel springs, 17-7 PH stainless exhibits retention of its mechanical properties, particularly at or above 450 °F. When mechanical performance and not necessarily corrosion resistance is the driving force in your application, 17-7 PH may be a good choice.

- Inconel® 718 – Inconel® 718 is a high-strength, corrosion-resistant nickel-chromium material that can be readily fabricated, even into complex parts. It has good tensile, fatigue, creep, and rupture strength resulting in its use in a wide range of applications. Though less common than many of the other alloys Maudlin offers, if Inconel® 718 is required, Maudlin can help

- Hastelloy® C-276 – NACE-approved material for extremely corrosive environments. Hastelloy® C-276 works well at elevated temperature but it is softer than the other spring materials which can lead to yielding if not carefully installed. It is recommended to consult our factory for assistance when specifying Hastelloy®.

- 17-7 PH Stainless Steel – Similar to the 300 series stainless steel springs, 17-7 PH stainless exhibits retention of its mechanical properties, particularly at or above 450 °F. When mechanical performance and not necessarily corrosion resistance is the driving force in your application, 17-7 PH may be a good choice.

Ask an Expert

Have Questions? Contact one of our many MW design, engineering, or manufacturing experts to find out specifics on capabilities, product features, or discuss customizations.