Four Slide / Multislide Stamping

Four slide or multislide stamping is the process of forming metal material into its desired form using multiple slides that work together to bend or stamp the material in alternating directions based on programmed functions. The number of possible bend directions is determined by the number of slides on the machine.

ADVANTAGES OF WORKING WITH MW COMPONENTS

- Knowledgable engineers with a variety of industry experience

- Many of our machines allow for stamping in up to 14 directions

- Variety of customization

- Precise EDM wire cutting used in tooling

- Engineering assistance available

- Optional value-added services (prototyping, kitting, assembly, and more)

Why Choose Multislide Technology?

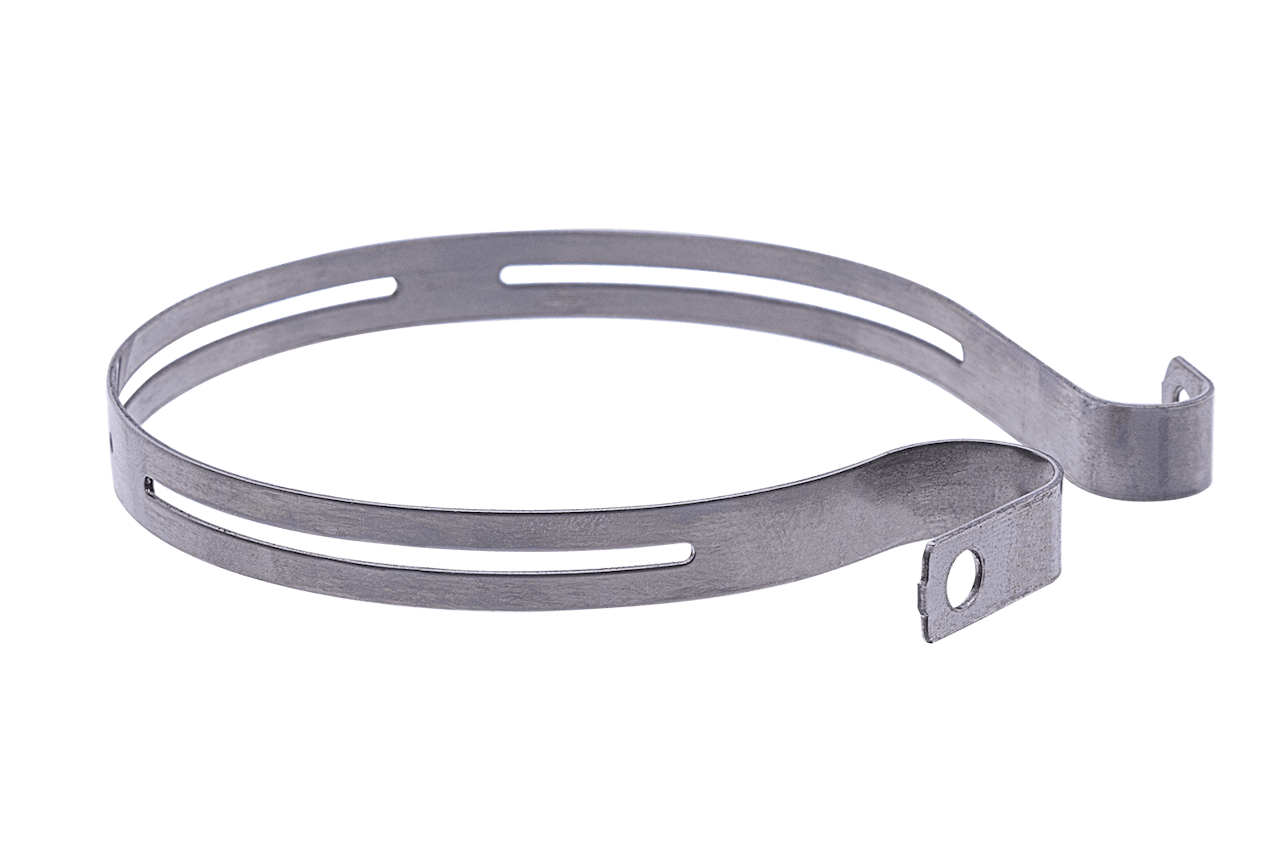

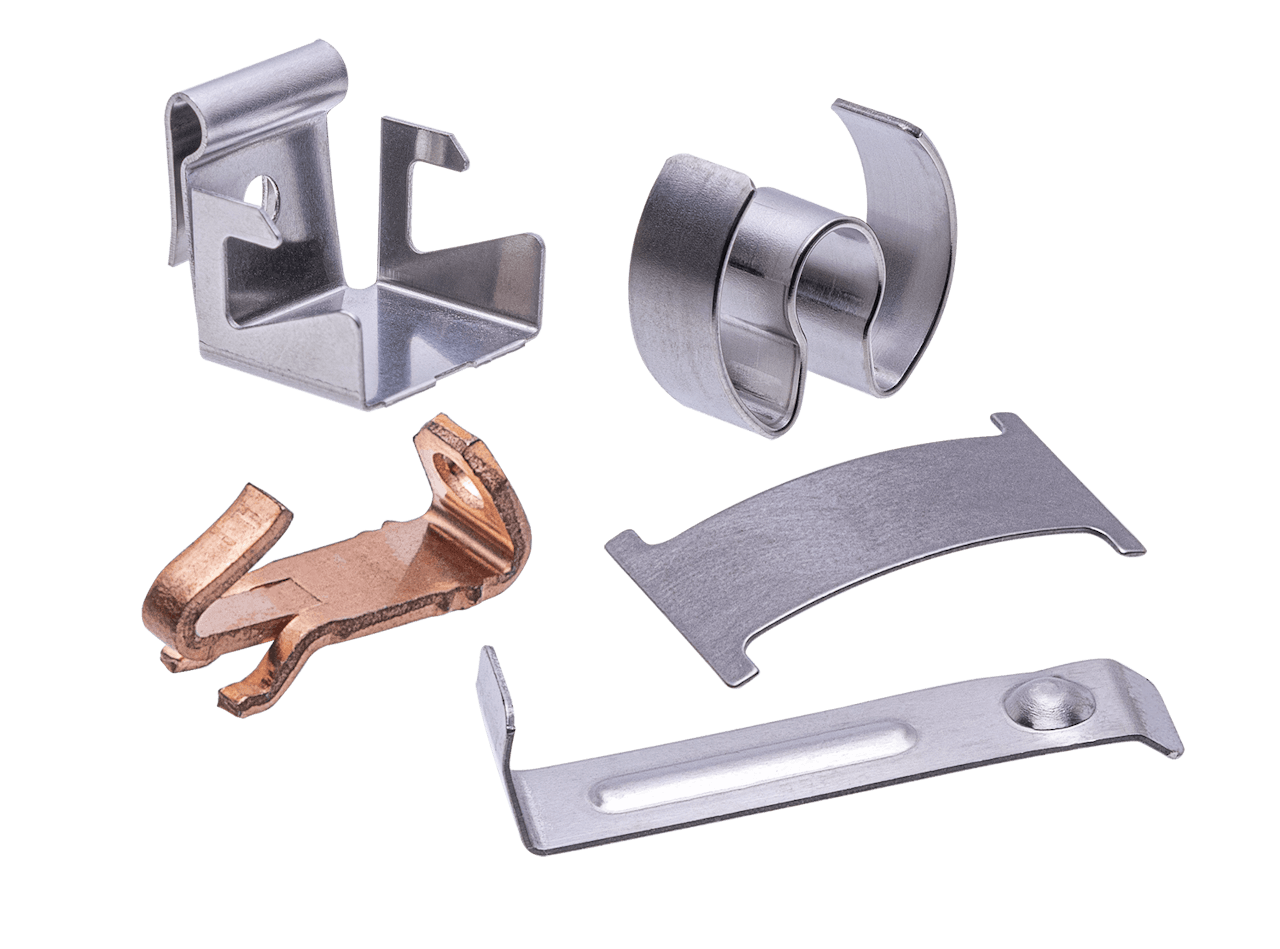

Four slide technology is used to produce several types of parts including wireforms, rings, clips, flat springs, leaf springs, clamps, and brackets. It allows for a great variety in customization for unique configurations. As a custom manufacturer, MW Components produces custom parts including custom metal stampings for various applications and industries.We use a variety of machinery to perform these functions including standard three and four slide machines as well as several rotary machines with up to 14 bending slides. Our vast selection of machinery ensures flexibility with the types of custom parts we can produce and industries we can service.

Four Slide & Multislide Machine Types

Rotary Multislide Machines

At MW Components, we use EDM wire cutting to cut tooling and press or stamp parts using either rotary multislide machines capable of bending in 10-14 directions or standard three and four slide machines. Our rotary machines also include a press area which allows for stamping. The type of machinery used during the production of your parts will depend on your application.

The following is a list of rotary machines we tool into and their maximum material sizes.

Four Slide Machines

The following is a list of the standard four slide machines we tool into and their maximum material sizes.

Custom Parts & Products

MW Components produces several four slide and multislide products. Examples of commonly requested parts are listed; however, we are a custom manufacturer and have access to a variety of manufacturing techniques and industry experts, allowing us to offer endless options for customization. Contact us for a custom quote to learn more.

Materials

Our four slide stampings are produced from a variety of materials and available in either plain finish or deburred. Some of the more commonly requested materials used in four slide and four slide stamping are listed below. If you require parts made from a material not listed here, contact us for a custom quote.

Industries Served

Four slide and multislide stamping are used to produce many custom parts for several industries, including industrial, commercial, electronics, military, pneumatics and fluid power, food service, metal finishing, and more. Some of the common industries we serve are listed below.