Cold Forming

What is Cold Forming?

Cold forming, also called cold-heading or roll-forming, is the use of applied force to metal blanks using a die. When pressure is applied, the metal material flows into the die, assuming the shape intended.

This process is generally preferred to traditional machining methods when expensive materials are used because it minimizes costly material waste. It is also an efficient process that is consistently reliable and eco-friendly. As a bonus, cold-formed components are stronger and more durable than components produced using other means.

Other production processes which use cold forming include thread rolling, and SEMs rolling. These processes are used most often in the production of cold formed fastener products.

To learn more about the cold-forming process, check out our process overview.

How Cold Forming Works

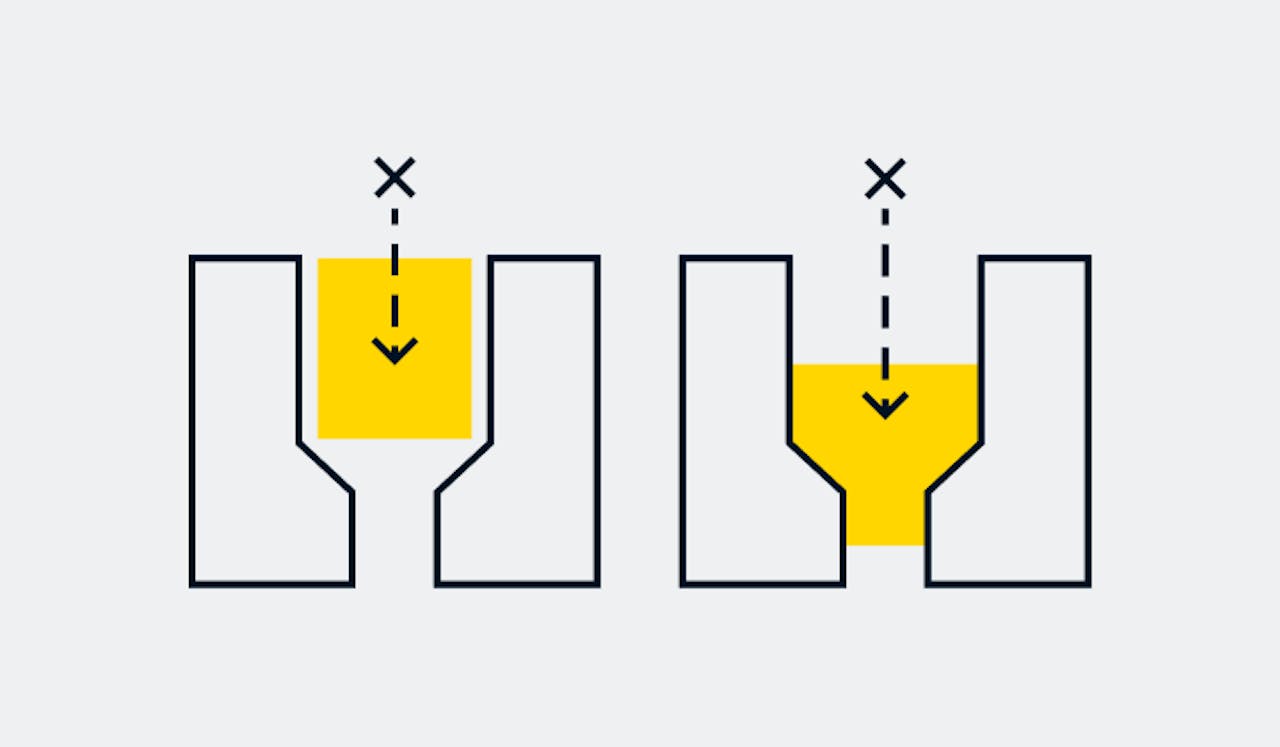

Cold forming creates favorable strain (work) hardening. With closed die cold forming, metal fills the space within the die cavity as it’s plastically compressed into the mold.

The closed die cold forming process can increase tensile strength of parts, especially under the head.

Closed die cold forming technology produces a highly accurate finished product that is repeatable at large volumes. Our high-speed, high-volume manufacturing capabilities make us the right partner for on-time delivery of the parts you need.

Benefits of Closed Die Cold Formed Components

- Reduced material scrap compared to machining

- Strengthened end product due to the flow of material grain

- Parts virtually free from burrs and rough edges through use of rounded dies

- Better utilization of materials with chipless production

Industries Served

Cold forming is used most often to produce micro components or miniature parts. These small components are used in various industries, including the below.

Custom Applications

MW Components produces several cold-formed or roll-formed products. Examples of commonly requested products are listed here; however, being that we are a custom manufacturer, we have access to a variety of manufacturing techniques and industry experts, allowing us to offer endless options for customizations. Contact us for a custom quote to learn more.