Products > Springs > POP Display Solutions

Slideline™ Pusher Systems

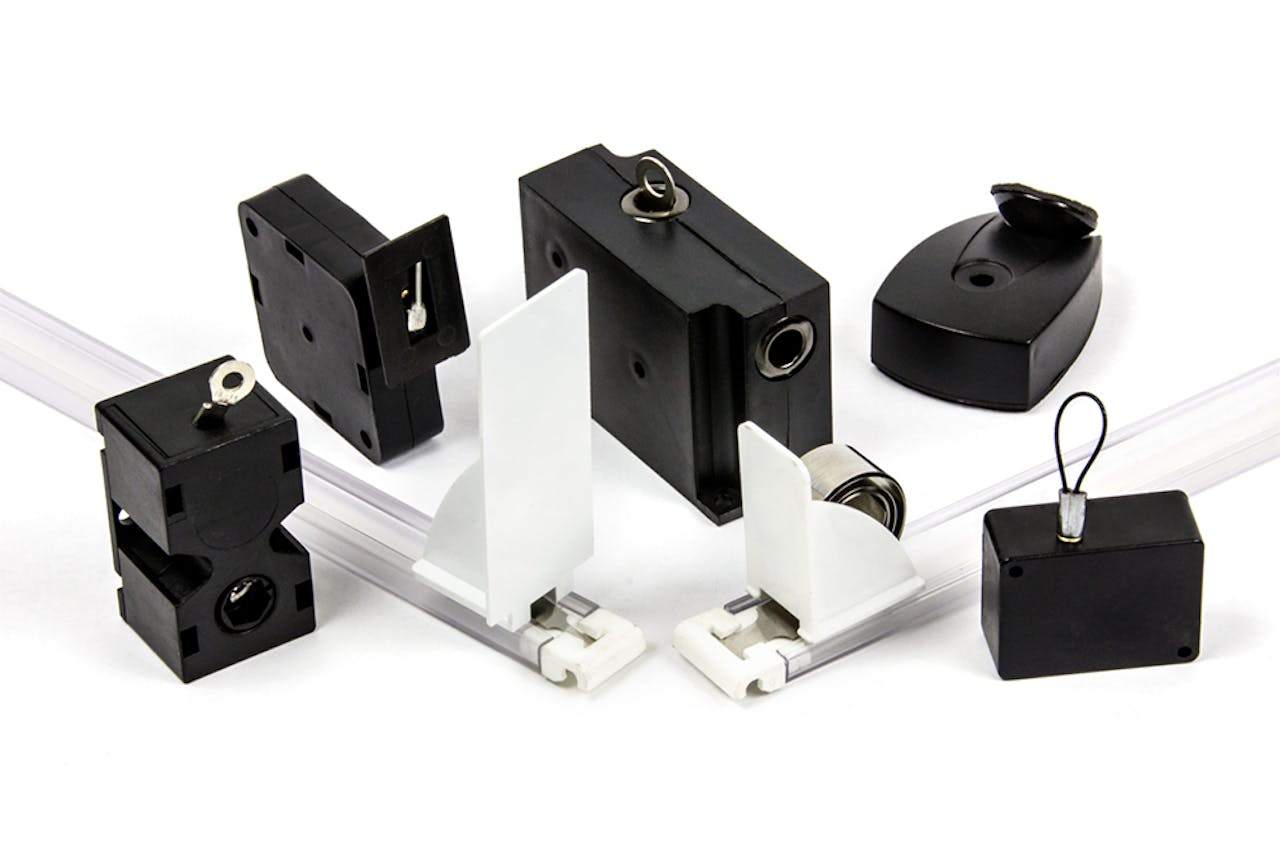

Slideline™ Pusher Systems are generally used in closed retail environments like food and beverage coolers or supermarket and convenience store displays to ensure organization and visibility of the product. Tension created by springs forces new product to the front of the unit as items are removed.

Free Sample Kits

If you would like to request a free sample kit to test our pusher systems for your design or application or coordinate shipping an example of your existing trays and product for us to assist in making a recommendation, fill out our Custom Quote form and we will reach out with more information.

Request a Quote

CUSTOM MANUFACTURING

Custom Slideline ™ Pusher Systems

Slideline™ Pusher Systems can be customized to fit any shelf size and fixture configuration. Additionally, MW has access to a variety of materials and finishing processes to ensure that the pusher system we develop for your application suits your product’s necessary environment. Heat, cold, high-humidity—no matter the environment, we have a solution for you.

Send us your specs or configure a product.

Slideline ™ Pusher Systems Manufacturing

Slideline™ Pusher Systems maintain appealing merchandise displays by utilizing spring tension that automatically repositions the product after one or several units are removed.

We make Sideline™ Pusher Systems in a variety of sizes and tension strengths. We even offer laser etching services which can help the end-user easily identify which spring to install in which location in a multi-unit application. Our high-speed lasers can etch alpha, numeric, bar codes, logos, and graphics on the springs during the manufacturing process.

Not sure where to start? Our highly trained staff of engineers and specialists are always on hand to assist with design, development, and manufacturing processes.

Other POP Display Solutions Products

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.