Products > Bellows / Couplings

Servo Couplings

MW Components' servo couplings are produced using Helical® Flexure Technology and are offered in many different attachment styles as well as a vast array of sizes and materials to suit your specific application and/or custom requirements. Maintaining optimum system performance relies on properly matching a shaft coupling based on your specific performance and application requirements and standards. At MW Components, we have taken the guesswork out of selecting the precise servo coupling for your application by factoring in critical component dynamics such as shaft misalignment, space requirements, torque, and RPM.

CAD files for stock and standard servo couplings are available for download in MW OnDemand.

CUSTOM MANUFACTURING

Custom Couplings

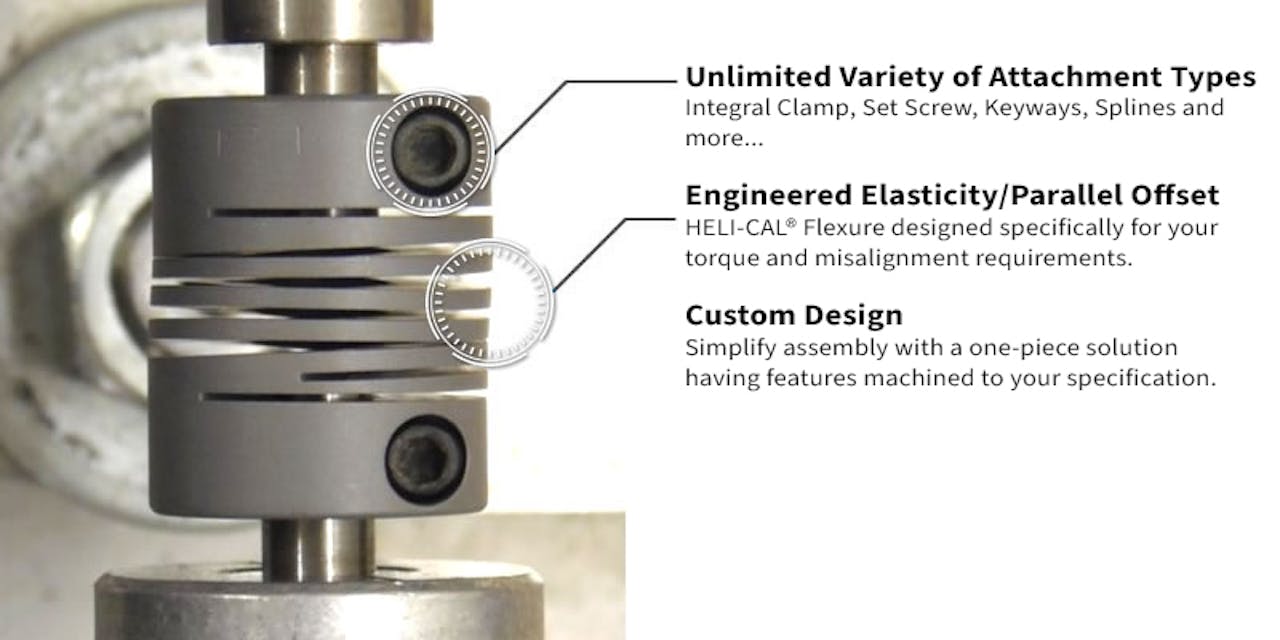

MW's vast machining capabilities allow us to design custom servo couplings for various industries and applications while meeting your torque and misalignment requirements. With an unlimited variety of attachment styles including, Integral Clamp, Set Screw, Keyways, Splines, and more, you can be assured that our custom engineered solution will suit your specialized needs and exacting specifications.

Send us your specs or configure a product.

Servo Coupling Manufacturing

Our servo couplings are produced using either aluminum or stainless steel using various machining services; however, specialty materials and services are also available for custom components. Multiple attachment styles are also available for added functionality. Torque range, bore ranges, operating temperatures, speed, and other performance factors will vary depending on the configuration chosen.

Characteristics

Servo-beam motor couplings can be produced using various materials, finishes, and cut configurations. They feature lower torque and torsion stiffness when compared to other coupling styles and can include a wide range of bore sizes, .094” - 1.0” SAE (3mm – 22mm), with zero backlash.

Beam Coupling Details & Configurations

- Best for accommodating shaft misalignment

- Many options in material, finish and cut patterns.

- Features low torque and torsional stiffness (in comparison to other types of servo couplings)

- Wide range of bore sizes; .094” to 1.0” SAE (3mm to 22mm metric)

- Zero-backlash

For more details on available beam coupling configurations, review the list below for a side-by-side comparison.

Coupling Selection Tools & Resources

Other Coupling Products

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.