How to Select a Tapered Spring

MW Components' Century Spring location offers a large selection of springs that are in-stock and ready-to-ship, including a wide variety of tapered springs. To order, shop our selection of stock tapered springs or, if you don't see what you need in our online store, request a quote for custom springs.

About Tapered Springs

We stock a large selection of conically-tapered compression springs. This configuration of this spring is characterized not only by its shape, but also by the fact that its rate is normally non-linear. There is a necessary increase in the applied force to compress the spring due to the flexibility of the larger diameter coils causing progressive contact with one another. This characteristic can be a plus for spring-supported vibrating objects by reducing the resonant (bouncing) amplitudes commonly found in constant-diameter, spring-supported systems.

The conical spring has more lateral stability and less tendency to buckle than regular compression springs. Probably the most beneficial characteristic of this spring is that it can be designed so that each active coil fits within the next coil.

Note: If the spring needed for your application cannot be found in our online store, we can fabricate it for you. If you'd like a custom tapered spring, please request a quote.

Tapered Spring Design Information

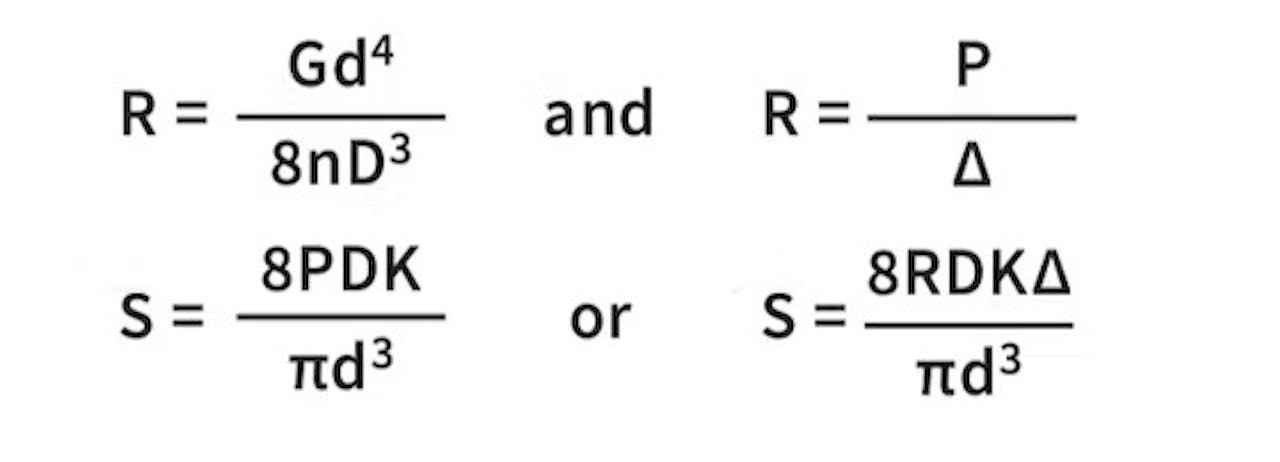

Finding Spring Rate and Stress

To calculate the highest stress at a given load or deflection for a tapered spring, the mean diameter of the largest active coil is input into the equations on the right.

An approximate rate for a tapered spring can be calculated by inputting the spring's average mean diameter into the rate equation on the right. The rate for a tapered spring becomes non-linear once the larger diameter adjacent coils come in contact with one another during compression. This loss of active coils will cause it to become stiffer. The rate noted in our inventory listing is the approximate rate (average rate).

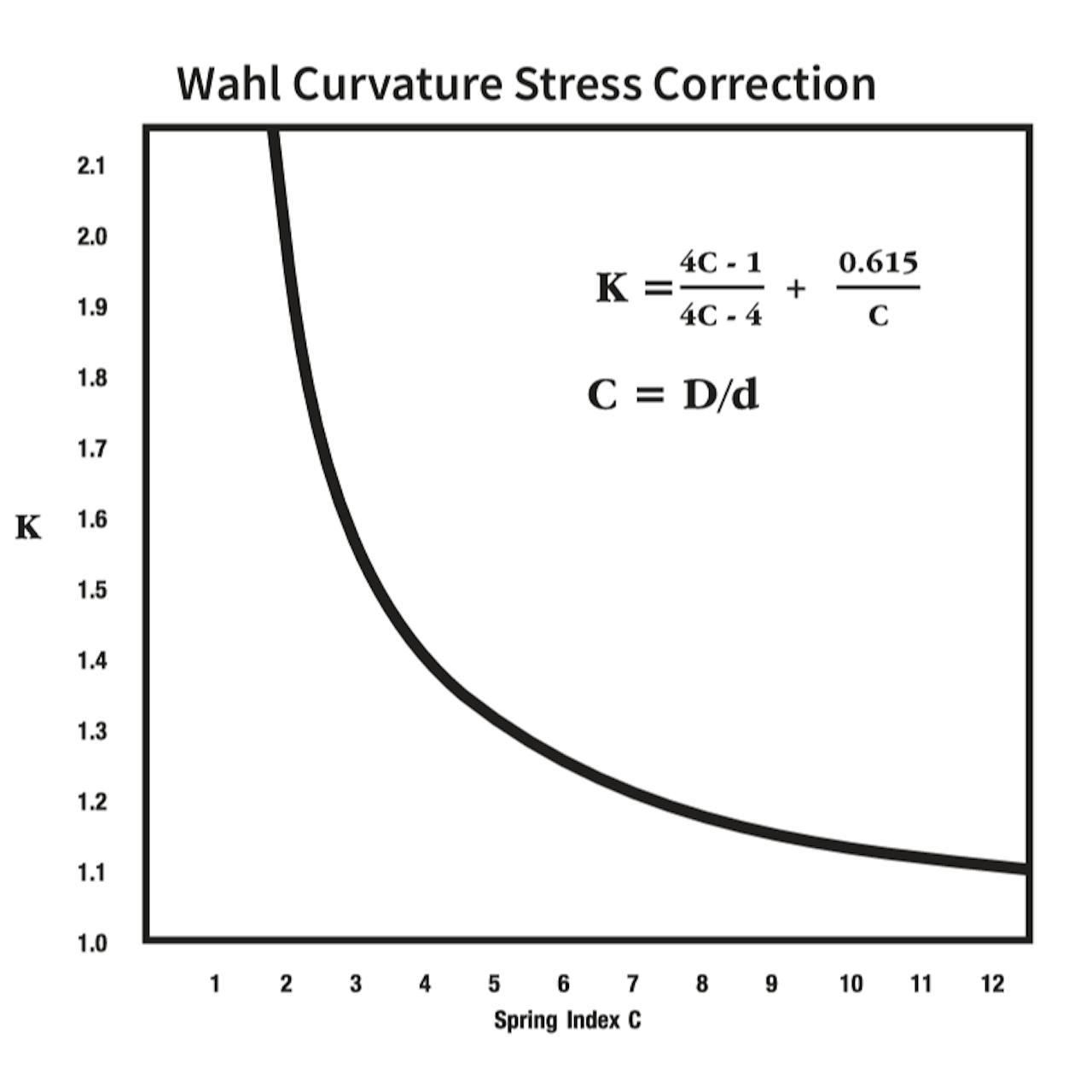

Note: One should not employ the curvature (k) correction stress in an expression solving for deflection. Use the uncorrected stress only, or errors will occur. The uncorrected stress can be used for static applications.

Where:

D = Mean diameter, (O.D. - d) inches

d = Wire diameter, inches

G = Modulus (spring steel = 11.5x106, stainless = 10x106), p.s.i.

K = Stress correction factor (see plot below)

N = Number of total coils

n = Number of active coils

P = Applied load, pounds

p = Pitch, distance between centerlines of wires of adjoining coils

R = Spring rate, pounds per inch (lbs./in.)

S = Wire stress, psi

Δ = Deflection, inches

π = 3.14

Minimum Tensile Strength

Minimum Tensile Strength (MTS) values vary with the spring-wire diameter. Further, 30 to 45 percent of the MTS value, depending on the material type, is used as a corrected stress target to produce a long fatigue life. For more information on MTS values by material type, ask an expert. For custom spring designs, request a quote.

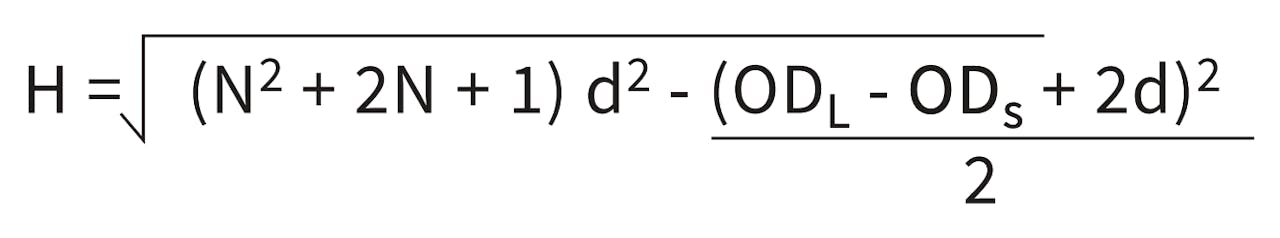

Finding the Solid Length Limit

Aside from any stress limits, the solid (minimum) length limit of a uniformly tapered, not fully-collapsible spring with closed ends, can be estimated from the equation on the right where:

H = Final height (length), inches

d = Wire diameter, inches

N = Total number of coils

u = Largest O.D. minus smallest O.D. divided by 2n

ODL = O.D. at the large end, inches

ODS = O.D. at the small end, inches

NOTE: The tapered spring's minimum compressed length may be stress limited. Contact us for details.

Tapered Spring Characteristics

-

Materials

The highest grade of spring wire is used for fabricating our springs. Certifications of conformance for geometric tolerances are available for our stock springs upon request. The following materials are used in the fabrication of our tapered springs.

• Spring Steel (music wire, hard-drawn wire, oil-tempered wire)

• Stainless Steel 302

• Phosphor-BronzeWe can provide material certifications and springs made from unique materials. Request a quote for more information.

-

Finish

The finishes available for our tapered springs include:

• Zinc

• Gold Irridite®

• Black Oxide

• Passivated (upon request)

• None (can be plated upon request)

Contact Us

For further design and engineering resources, visit the MW Components resource center or for specific questions related to our products or services, contact us.