Heat Treating Elgiloy Spring Products

Features and Benefits of Heat Treating Elgiloy Spring

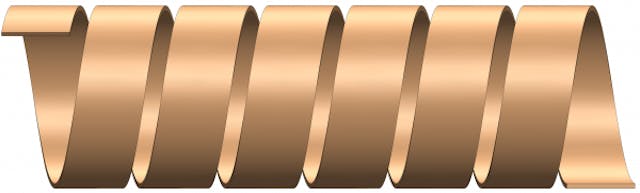

In general terms, heat treating is the closely controlled process of heating and cooling a material to achieve improved mechanical properties. Heat treating in metals is about controlling the size of the grain structure which in turn improves properties such as toughness, shear strength, and tensile strength. In the case of MW springs, this can mean a more durable product with increased wear resistance and higher loads. A change in color may also occur.

The process itself includes cold reduction and an elevated temperature soak. The cooling rate should be air cool or faster. Annealing is not recommended for Elgiloy. Cleaning must take place in an Alkaline bath prior to heat treatment.

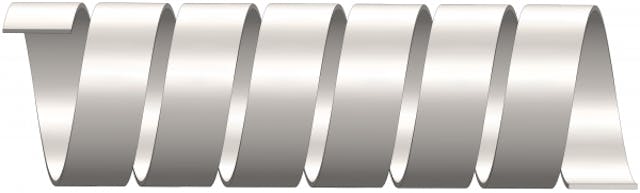

See below for examples of pre-heat treatment and post-heat treatment.

Heat Treated Elgiloy Applications

These are just a few examples of how a heat-treated spring can help you solve tough sealing applications. Contact MW for more information on a specific spring or application.

- Extreme cryogenic applications requiring added mechanical strength from the spring

- Large delta T applications requiring consistent spring force

- Light gas applications requiring high initial loading without spring yielding

Ask an Expert

Have questions about this or other products, materials, or services? Ask an MW expert for more details.