Spring Technology for the 21st Century

Introducing HELI-CAL® Flexure Technology

The HELI-CAL® Flexure is a flexible helix (curved beam) machined into a unique configuration that incorporates special design requirements, performance features, and/or characteristics. The material used is basically unlimited.

When used as a spring, the multifunctional flexure provides desired and predictable elastic performance in compression, extension, torsion, lateral bending, and lateral translation modes.

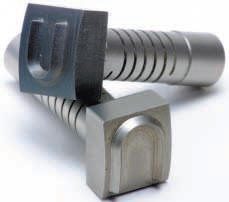

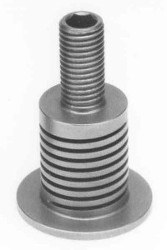

One huge advantage of this technology—it enables customer-specified end-attachments, such as tangs, clamps, flanges, or threaded ends, to be integrated into a single multi-functional component.

Request a quote to order machined springs made with HELI-CAL® Flexure Technology.

Features and Benefits of Machined Springs

- Finite element stress analysis (FEA) with Ansys

- Modal analysis

- Accommodates a wide variety of integrated attachments

- Includes pure spring reactions for torsional applications

- Incorporates multiple start configurations to eliminate extraneous reaction forces and moments, (buckling)

- Provides unlimited variations

- Offers multi-functionality expertise

Materials:

- High strength corrosion-resistant materials such as stainless steel

- High strength aluminum

- High strength titanium

- All machinable alloys

- Machinable plastics

Materials most used: Stainless steel 17-4PH, 15-5PH, 303, 316, 416, 18-8, Custom 455 maraging,C300 and C250, 718, 4340, H-11, Beta C Titanium, Delrin 150, Aluminum 7075-T6.

Capabilities / Services:

- Over 40 years of manufacturing and engineering excellence

- Complete in-house engineering design and manufacturing

- Quality assurance

- Precise spring rates

- Prototypes and short runs to high volume production quantities

- Fast turn around and delivery

- Unmatched dedication to quality and customer satisfaction

- “Multi-start” flexure construction (more than one spring coil set) provides a broad range of spring rates and functionality within a given envelope. Provides a redundant coil to resolve lateral forces.

- Precision machining of complex, multi-featured configurations

Integrated Attachments for Machined Springs

| Threaded ID and OD | Integrated Flange | Double Start Flexure | Heat Dissipating Spring |

|  |  |  |

| Hubble telescope | Aerospace application | Cryogenic cooler application | Used with lasers |

| Material: Beta C Titanium | Right and Left-Handed Flexure | Threaded Ends | Capacitor Terminal |

|  |  |  |

| 240° torsional spring | Triple start, torsional spring | Mars Rover | Aircraft electronics |

| Four Functions In One | Tapered Flange | Beefed Up Radius on Tangs | Four Elastic Rates Incorporated |

|  |  |  |

| Now one piece with Helical wrap spring clutch | Single start, compression spring | One-piece, wrap spring clutch | Medical application, five start spring |

| Constant Pivot and Rotary | Material: 17-4PH | Integrated End Attachments | 0.125″ Flexure OD |

|  |  |  |

| Medical application Torsion spring | Industrial knife application | Machine tool application | Commercial lateral spring |

Coil Geometries

Differences in coil geometry enable machined springs to provide more precise performance, features, and functions than can other, more traditional types of springs. There are big differences in performance, reliability, versatility, integrity, and cost-effectiveness. See the example below.

|  |

| Before Wire-wound spring Three pieces | After Machined spring Single piece Integrated parts-functions |

The bottom line:

- Machined springs offer more functions in a single spring than other more traditional springs, such as wire-wound.

- They add value, in terms of multipart integration, time saved in handling, reliability, rates being linear, and dimensions being very precise.

- Machined springs reduce and/or control costs.

- And they raise overall productivity, i.e., add more, do more, save more dollars.

Machined Springs vs. Wire-Wound, Which is Right for Your Application?

| Consideration | Wire-Wound Springs | Machined Springs | Notes |

|---|---|---|---|

| Perform basic elastic modes | Yes | Yes | Machined springs have distinct multi-functional advantages. |

| Relatively inexpensive | Can be | Depends | Both types can be expensive or inexpensive. |

| Available in different materials | Limited | Yes | Machined springs can be produced from anymachinable material. |

| Multi-function – feature capability | Limited | Yes | Machined springs can contain many dimensional features. |

| No stress to overcome before deflection | No | Yes | Machined springs have a more precise force deflection relation. |

| Can reduce assembly costs | Unlikely | Yes | Incorporating multiple features into a single partdesign makes assembly easier & cost effective. |

| Can contain redundant elastic elements (multiple starts) | No | Yes | Machined spring rates are linear. |

| Quality – reliability | Depends on manufacturer | Yes | Dimensional variances are typically smaller inmachined springs. |

| Precision elasticity | Difficult | Yes | Variation rates in machined springs are typicallylow. |

| Integration with other products | Difficult | Yes | Design it into your system, not around it. |

| Reduction of system complexity | Difficult | Yes | Simplify your system by incorporating multiplecapabilities into a single part. |

| Custom-end configurations added to spring | Difficult | Yes | One of the major advantages of machined springs. |

| Longevity achievable? | Yes | Yes | Machined spring’s long life can benefit from multi-start configurations (double and triple starts). |

| Possible Configuration | Wire-Wound | Machined Spring |

|---|---|---|

| Extension spring | Yes | Yes |

| Compression spring | Yes | Yes |

| Torsion spring | Yes | Yes |

| Lateral bending spring | ? | Yes |

| Lateral translation spring | ? | Yes |

Ask an Expert

Have questions about machined spring products, including materials, configurations, or attachments? Ask an MW Expert.