Products

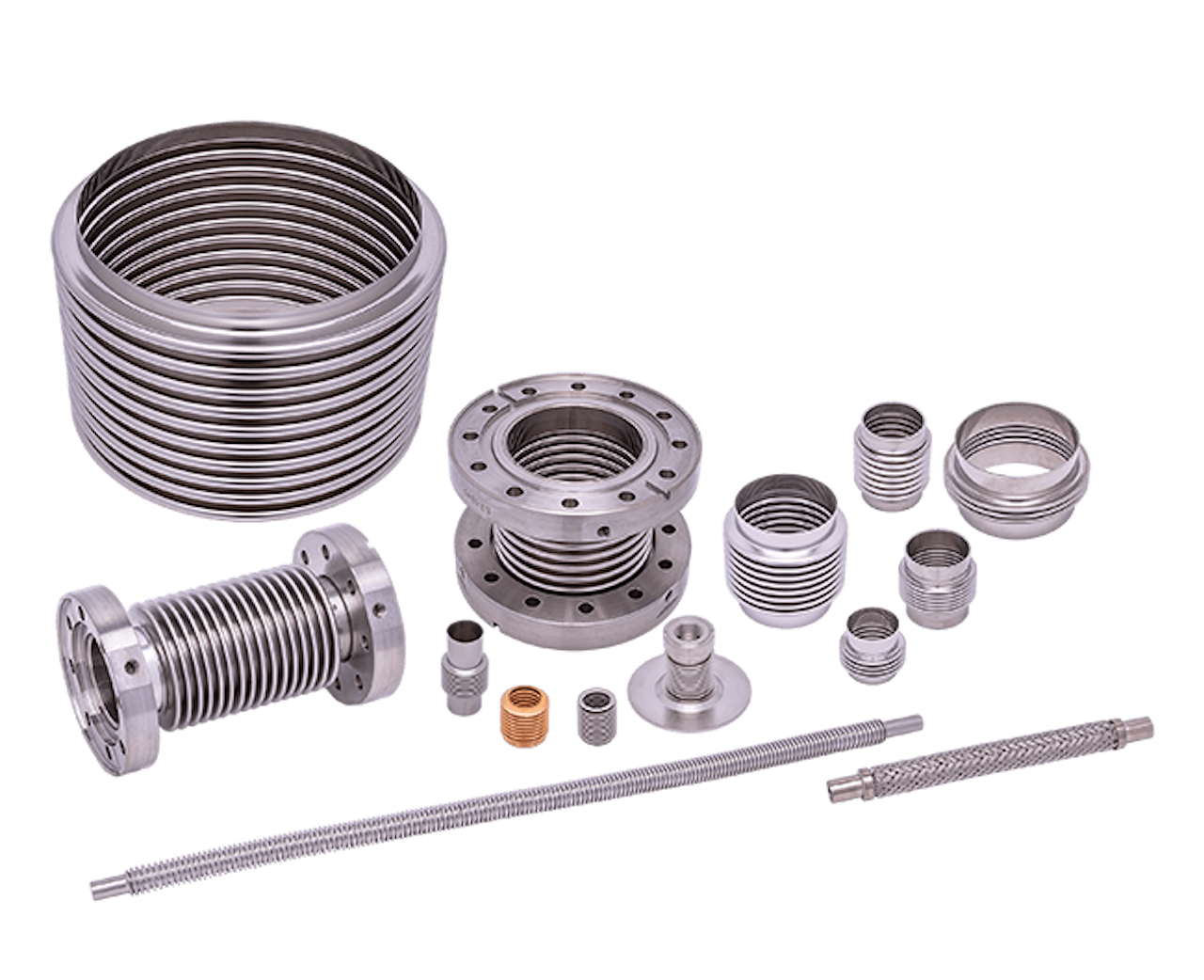

Formed Metal Bellows

Ameriflex manufactures top-quality formed metal bellows including slip joint bellows for IndyCar and NASCAR racing. For many years we have manufactured and supplied Inconel slip joint bellows for the turbocharger applications of such racing teams as Penske, Newman & Haas, Players Forsythe, Patrick Racing, Target Chip Ganassi, and others. These exhaust manifold components are designed to absorb heat and vibration generated by race cars’ high-performance engines.

Our standard formed bellows are produced using stainless steel; however, we also work with a variety of specialty metals, including Inconel, which can withstand extreme temperatures without compromising performance. We manufacture our formed bellows, including slip joint bellows and other bellows products to our customers’ unique specifications for bend radius, pitch, etc. Our precision CNC manufacturing capabilities allow us to maintain design tolerances within a few thousandths of an inch. Request a quote to learn more.

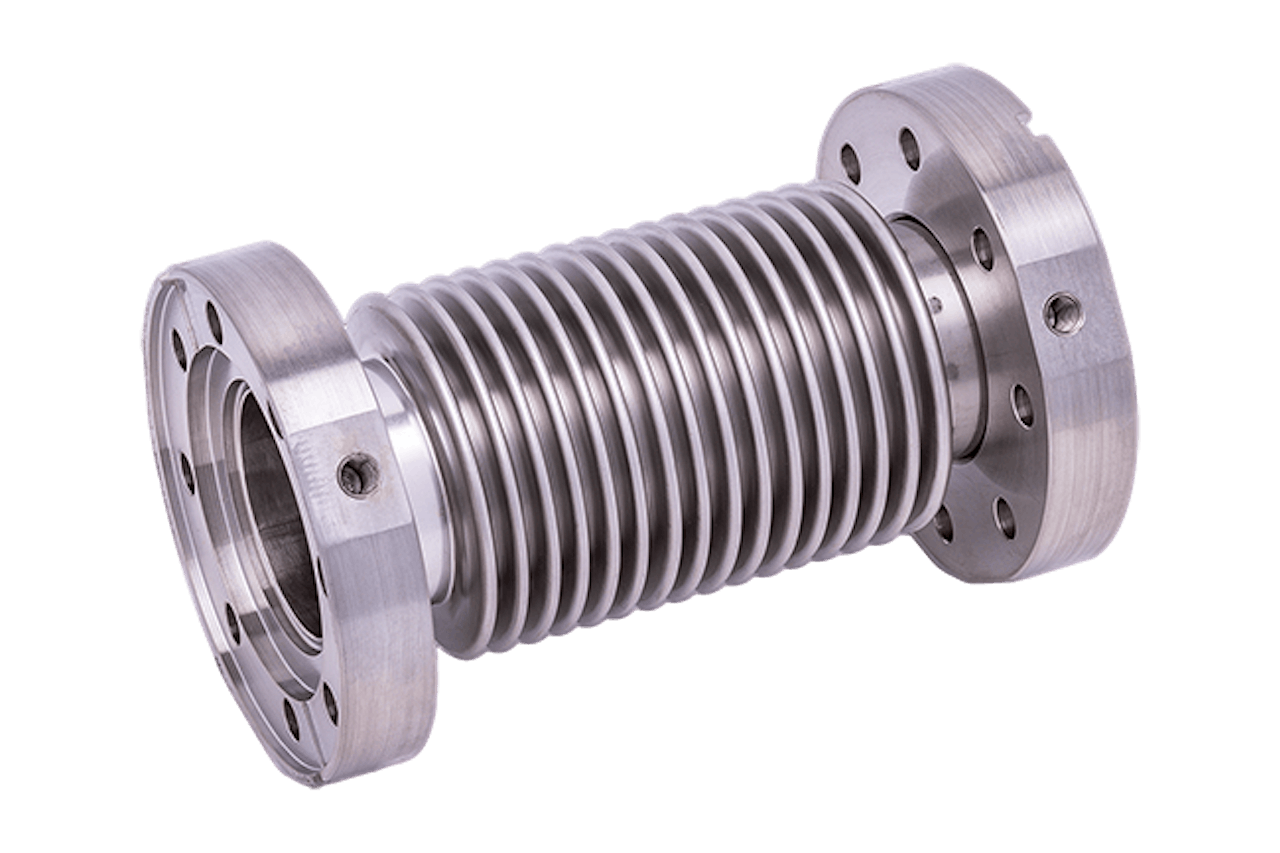

Formed Bellows Assemblies

Ameriflex produces a full line of bellows assemblies to complement our metal bellows. We manufacture bolt-style and clamp-style bellows assemblies bellows valve assemblies, expansion joints, flanges, and more. Every bellows assembly we make is ultrasonically cleaned prior to welding, and helium leak tested after to ensure weld integrity and defect-free construction.

Our bellows assemblies are either built to meet customer specifications or designed by our expert team of in-house engineers to meet our customer’s unique requirements. Our 40+ years of metal bellows manufacturing experience and CNC machining capabilities help us create vacuum fittings with the perfect combination of diameter, length, and wall thickness, and produce tolerances within a few thousandths of an inch.

We manufacture our bellows assemblies from only the highest quality, domestically sourced or DFAR-compliant materials, including stainless steel, other alloys, and a variety of specialty metals. Our in-house precision CNC manufacturing capabilities allow us to manufacture fittings for your assemblies and maintain tight design tolerances. Request a quote to learn more about our formed metal bellows and assemblies.

Expansion Joints

Ameriflex produces expansion joints and stainless steel hose for many industries. Expansion joints create flexibility and absorb thermal expansion or movement within assembles, making them ideal for use in cryogenic applications, which undergo continual exposure to extreme temperatures.

Our custom expansion joints are produced to precise tolerances as required by your application and industry. We manufacture expansion joints using state-of-the-art equipment and high-quality Nadcap-certified welding processes. We offer on-site testing to ensure the highest quality and longest cycle life and performance of your assembles.

Bellows Valve

Bellows valves or bellows seal valves are used to prevent leakage or control flow in piping systems.

Bellows valves are often used in sealing applications for aerospace, biotechnology, chemical processing, nuclear power, petroleum, pharmaceutical, and semiconductors.

Ameriflex manufactures standard and custom metal bellows and metal bellows assemblies, including bellows valve components. We either work with your specifications or our expert team of engineers works in combination with your team to determine the right specifications for your application. To order custom bellows including bellows valves, request a quote.

Flexible Metal Hose

Our flexible braided hose is designed specifically for high-pressure environments and is the highest-quality metal braided hose in the industry. It's produced to withstand high internal pressure and vacuum conditions. Our stainless steel braided hose is found on NASA's Curiosity Mars Rover, commercial spacecraft, and many other applications.

Ameriflex flexible metal hose is made to our customer’s unique specifications for diameter, length, end configuration, and other design factors. Our manufacturing expertise and precision CNC machining capabilities enable us to hold tight tolerances within a few thousandths of an inch.

We manufacture our stainless steel braided hose in sizes from 0.25" up to 10” in diameter. Available end fittings include male-to-female swivels, pipe threads, VCRs, VCOs, and more. Our metal braided hose is the #1 choice for any braided hose application. Request a quote to learn more about our custom flexible braided hose.

Metal Flanges

Ameriflex takes pride in manufacturing top-quality, round metal flanges for all types of assemblies. Flanges help secure and strengthen other vacuum components. They provide leak-proof connections for braided hoses, bellows assemblies, and other components. Our metal flanges are designed for years of continued service in extreme conditions.

Proper fit for flanges is as crucial as the components to which they’re connected. Ameriflex offers sizes ranging from 0.125” O.D. to 36” O.D. and above. We manufacture our flanges from 304 or 316L stainless steel, Inconel, brass, aluminum, titanium, Hastelloy, and other metals and alloys. We use only domestically sourced or DFAR-compliant materials for all our products and deliver 100% Made in the USA manufacturing.

Our flanges are manufactured to customer specifications and to complement the bellows or other neighboring components. Our machining capabilities allow us to produce flanges with tolerances within a few thousandths of an inch, and our in-house tooling shop allows us to create custom metal flanges that match your designs exactly. Ameriflex flanges also utilize “lock-on” collars that make them compatible with other manufacturers’ components. If you need C-rings, O-rings, or other precision-machined flanges, make Ameriflex your first choice. Request a quote to learn more.

Contact Us

Have questions about our services or need a quote? Contact us. You should hear from our team within 24 business hours or less.