Formed Bellows & Assemblies Manufacturing

Ameriflex offers close-tolerance CNC machining to deliver precision vacuum parts and other components for your application. We operate over 20 CNC lathes and mills, and a host of manual machines that supply you with the finest machined parts in the industry. If you’re looking for close tolerances—within 0.005”—or other high-precision machining, Ameriflex is ready to produce the high-quality parts you need, at competitive prices.

We produce prototypes and small and large production runs. Our skilled team of machinists utilizes state-of-the-art CNC machining equipment and software to manufacture your parts with perfect precision and repeatability. Ameriflex specializes in working with customer designs. However, our design team is available to assist as needed to ensure the optimization of your designs for faster, more efficient, and cost-effective production. Our in-house tool and die shop offers further cost-savings and fast turnaround, making us a one-stop shop for CNC-machined precision parts, like metal bellows, bellows assemblies, and flexible metal hose.

Request a quote for the CNC machined or vacuum components you need, or visit one of the below sections for more information about our manufacturing capabilities.

Request a QuoteWeldingHelium Leak Detection Quality ControlIndustries Contact Us

Premium Services We Offer

Welding

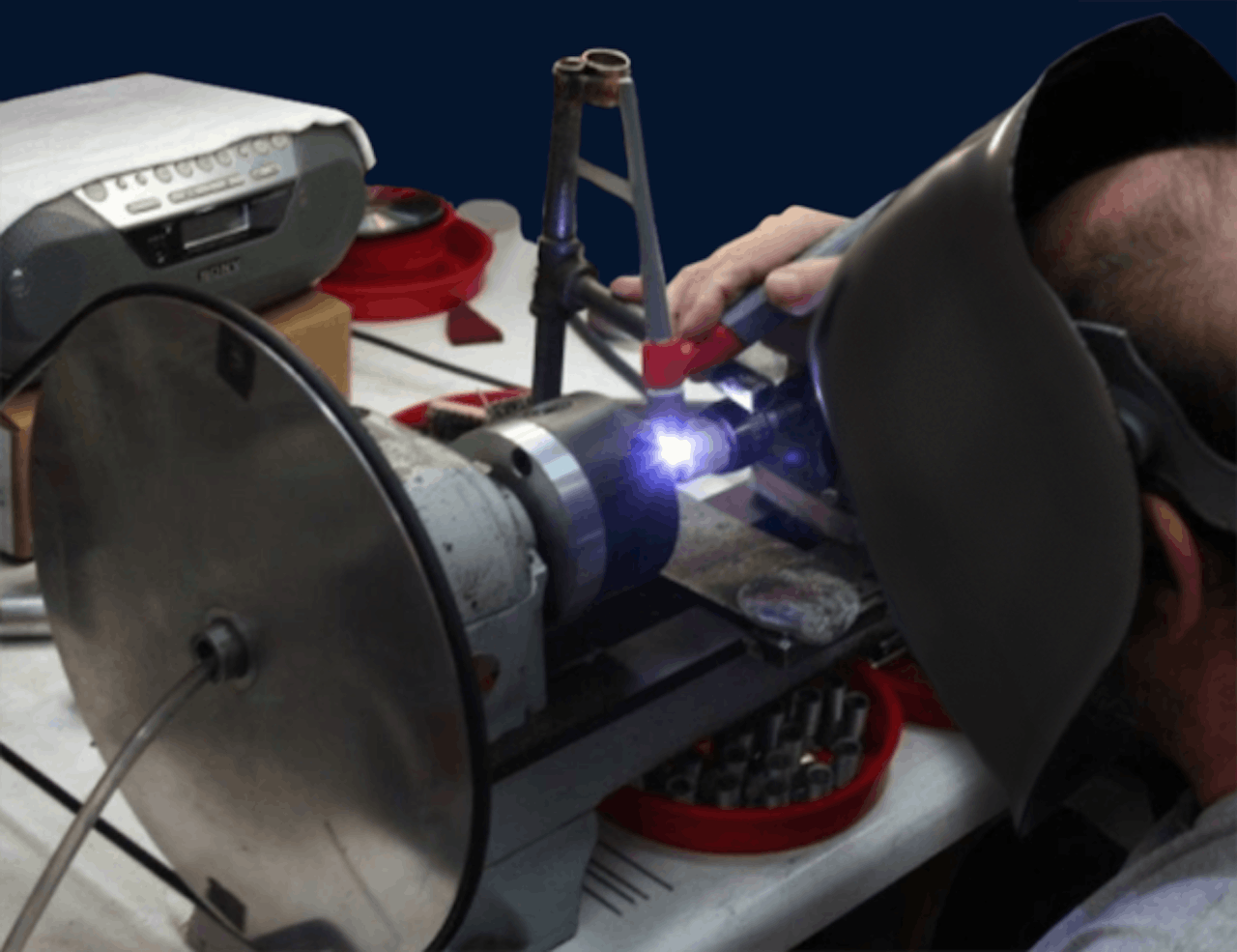

Here at Ameriflex, we take welding seriously. We hold numerous ASME welding certifications and offer TIG (tungsten inert gas), plasma arc, resistance, and seam welding capabilities to join many types of metals, including titanium, Hastelloy, stainless steel, and other high-nickel alloys.

We use manual, orbital, and automated robotic welding equipment to produce welds of superior quality and mechanical strength. Each of our professional welders has years of experience in creating low-distortion, visually appealing welds. All of our welds are subject to helium leak detection testing to guarantee leak-free design.

Our welding capabilities may be used in metal/alloy fusion processes to enhance structural integrity with cold filler metals, for full penetration welds, and for other purposes. Our equipment and expertise enable us to create welds that match the quality and reliability of our manufactured products.

Contact Ameriflex for more information on our wide-ranging welding capabilities and how they can improve your precision machined parts and components.

Helium Leak Detection

Helium leak detection is among the most reliable and effective testing methods available for testing the structural integrity of welds. It is a crucial process that has helped make us a leading manufacturer of vacuum assembly components.

Using helium mass spectrometers, we perform vacuum leak detection tests on all our welded parts and components. These precisely tuned, high-tech machines are sensitive to even the smallest leaks and are highly effective for testing large, complete systems and small, individual parts. Ameriflex guarantees each and every vacuum part will be functional and leak-free when it arrives at your location.

Contact us to learn more about vacuum leak detection and how it helps improve your parts.

Quality Control

- Engineering Collaboration

- Designs to Meet Industry-Specific Requirements

- State-of-the-Art Manufacturing

- On-site Performance Analysis & Testing

- Certifications for ISO 9001, AS9100D & Others

Industries

Our engineering team is well-versed in custom manufacturing for products for multiple industries, including semiconductors, fluid handling, hydraulics, electronics, cryogenics, lab and university research, and more. See more information below or contact us to learn more about custom applications not listed here.

-

Aerospace

AerospaceOur hydroformed metal bellows and flexible metal hose are found in fuel line pumps of commercial space transport crafts and on NASA's Curiosity Mars rover. We are able to meet the tight tolerances these applications require with perfect precision and repeatability.

-

Motorsports

MotorsportsAmeriflex supplies metal bellows for high-performance automobiles. Because the difference between winning and losing can come down to the smallest of measures, leading performers in the IndyCar and NASCAR circuits have made Ameriflex their first choice for slip joint bellows that their machines need.

-

Defense

DefenseOur metal bellows and flexible metal hose are found on various military aircraft, including F-15, F-16 Tomcat, F-18, and F-4 Phantom fighter jets. Mission-critical industries rely on us due to the tight tolerances we produce and the reliability our parts offer.

-

Cryogenics

CryogenicsOur metal bellows and flexible braided hose are used to help regulate temperature and pressure in liquid nitrogen and oxygen tanks, gas pumps, and various other cryogenic applications. Our components meet the tight tolerances and high-quality standards that these applications require.

-

Semiconductor

SemiconductorOur metal bellows are used in valve applications within chip manufacturing equipment. Our steel braided hose is found in roughing line applications, vacuum electronics manufacturing, and more. Every part and component we produce meets the tight tolerances and quality standards required by the semiconductor industry.

-

Medical

MedicalWe provide steel braided hose and precision bellows assemblies for pharmaceutical and prescription drug manufacturing, stainless steel bellows for cleanroom applications, manufacturing for orthodontic braces components, and more. Request a quote to learn more.

-

Energy, Oil & Gas

Energy, Oil & GasBellows often function in oil and gas applications to suppress pressure, control temperature, or prevent leakage of gas or fluids. Our metal bellows are built to handle tough environments, including high-pressure, extreme temperatures, and highly corrosive situations.

-

Lab & University Research

Lab & University ResearchLeading labs and universities like Brookhaven National Lab, Fermilab, and Argonne National Laboratory turn to us to deliver entirely custom components. From alternative energy research to particle beam science and beyond, our products meet or exceed the high standards of quality and precision required by advanced science.