Helical Flexure Engineering

Helical products are engineered with Helical flexure technology, which allows for a variety of more controlled movements while offering superior stability and longevity.

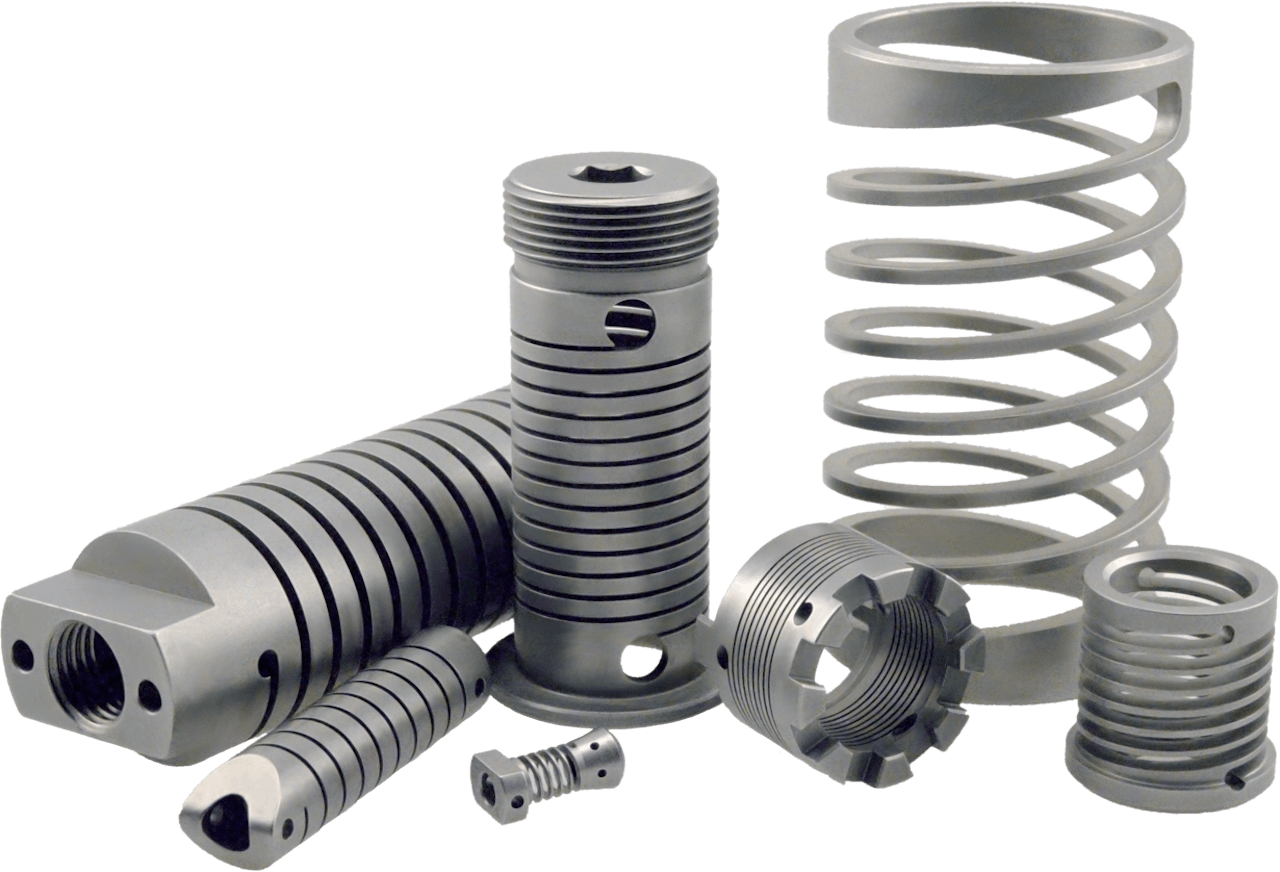

Our Helical flexures, also referred to as machined springs or Helical springs, are machined from a solid bar stock to your precise specifications. Solid materials typically include stainless steel, aluminum, engineered plastics, and exotic alloys. Machined springs, unlike wire-wound springs, offer greater flexibility of design, vastly improved cycle life, and allow for a single-piece solution that can replace multiple parts in spring assemblies. Helical flexure technology can also be incorporated into other components that accommodate for misalignments like flexible couplings and U-joints.

Helical flexures or Helical springs offer endless possibilities for several key industries; including, aerospace, aviation, medical, scientific, energy, and others.

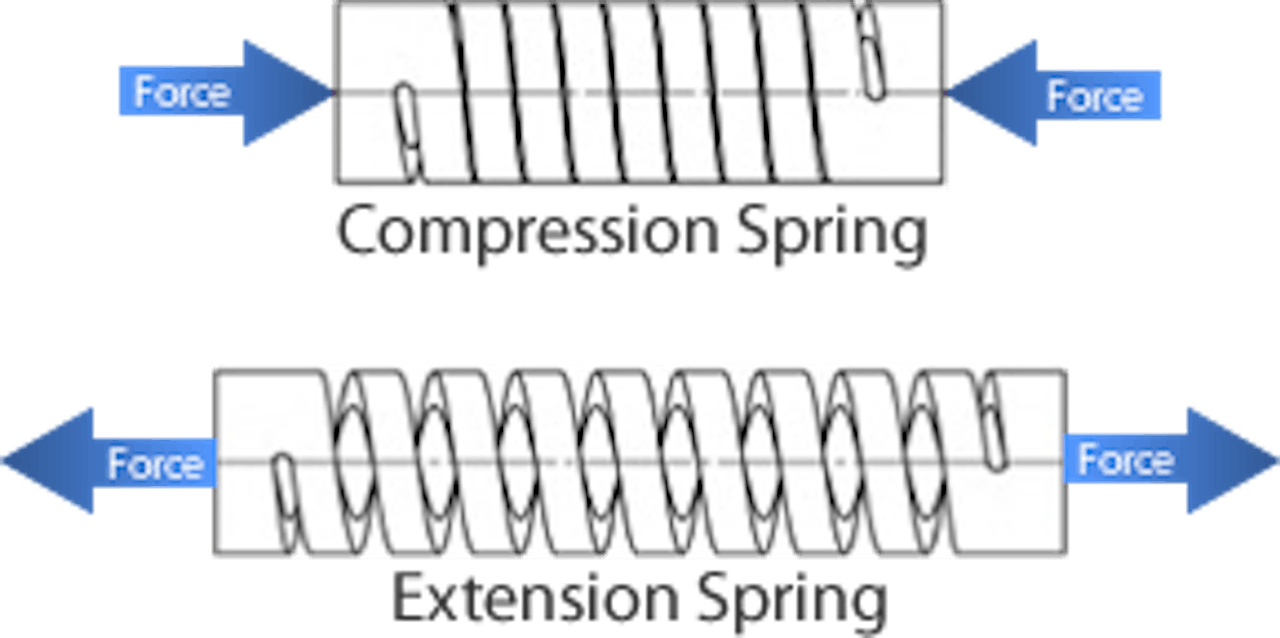

Compression & Extension Springs

Helical machined springs (Helical springs) provide very repeatable and linear, axial spring rates because of the absence of residual stresses often associated with traditional wire wound springs. A significant advantage of the Helical machined spring is the ability to provide multiple-start flexure (coil) configurations. Using the multi-start configuration (normally double or triple start) the unresolved moments common to single-start springs will prevent tipping and side loads during compression or extension. One additional benefit of the multi-start coil configuration is that it provides a level of system redundancy because more than one coil is transmitting the load. Another feature unique to machined springs is the ability to combine a right-hand and left-hand flexure in a single piece to prevent rotation which many types of springs exhibit during compression and extension. The ability to incorporate custom machined features as part of a single-piece elastic component makes our Helical springs the perfect solution for today’s demanding applications.

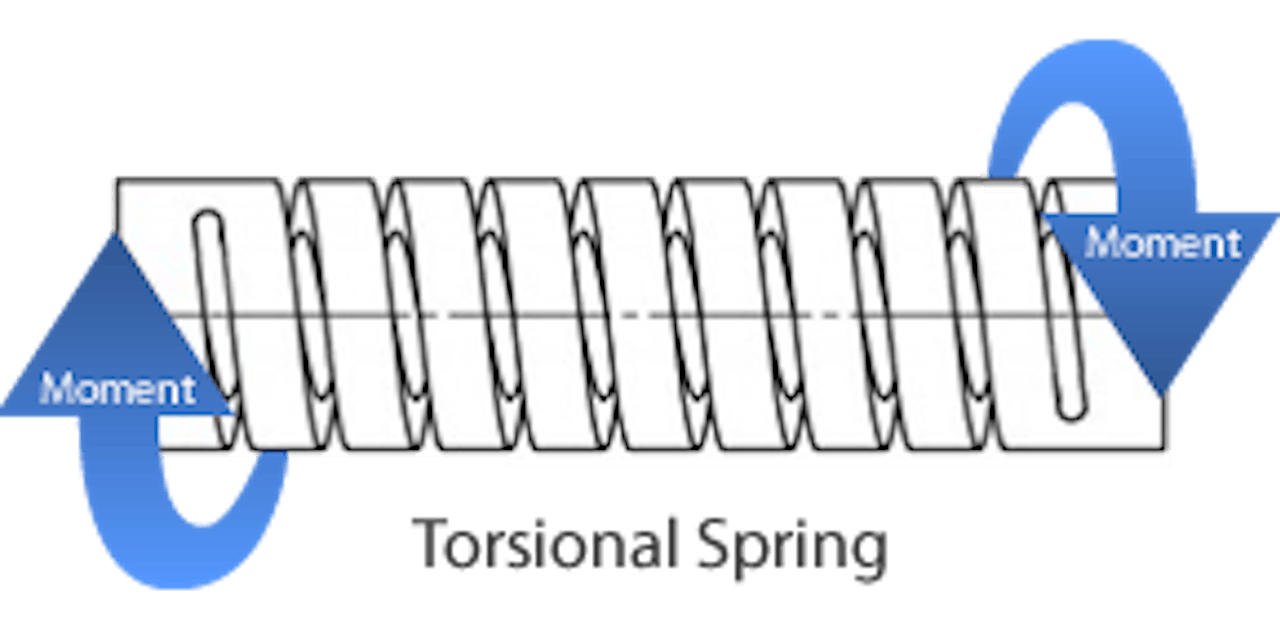

Torsion Springs

Endless design options are possible with Helical machined springs in torsional applications. Because attachment features can be integrated into a single-piece spring, the traditional challenges of how to transfer torque into a torsion spring will no longer be a concern. It is now easier than ever to use the versatility of integrated features to enable a pure moment in your torsion spring application. Gain smoother operation and added value by making a feature-rich Helical spring the solution to your design requirements. With linear rates and the potential for rate accuracies approaching 1%, outstanding performance will set your design above the rest.

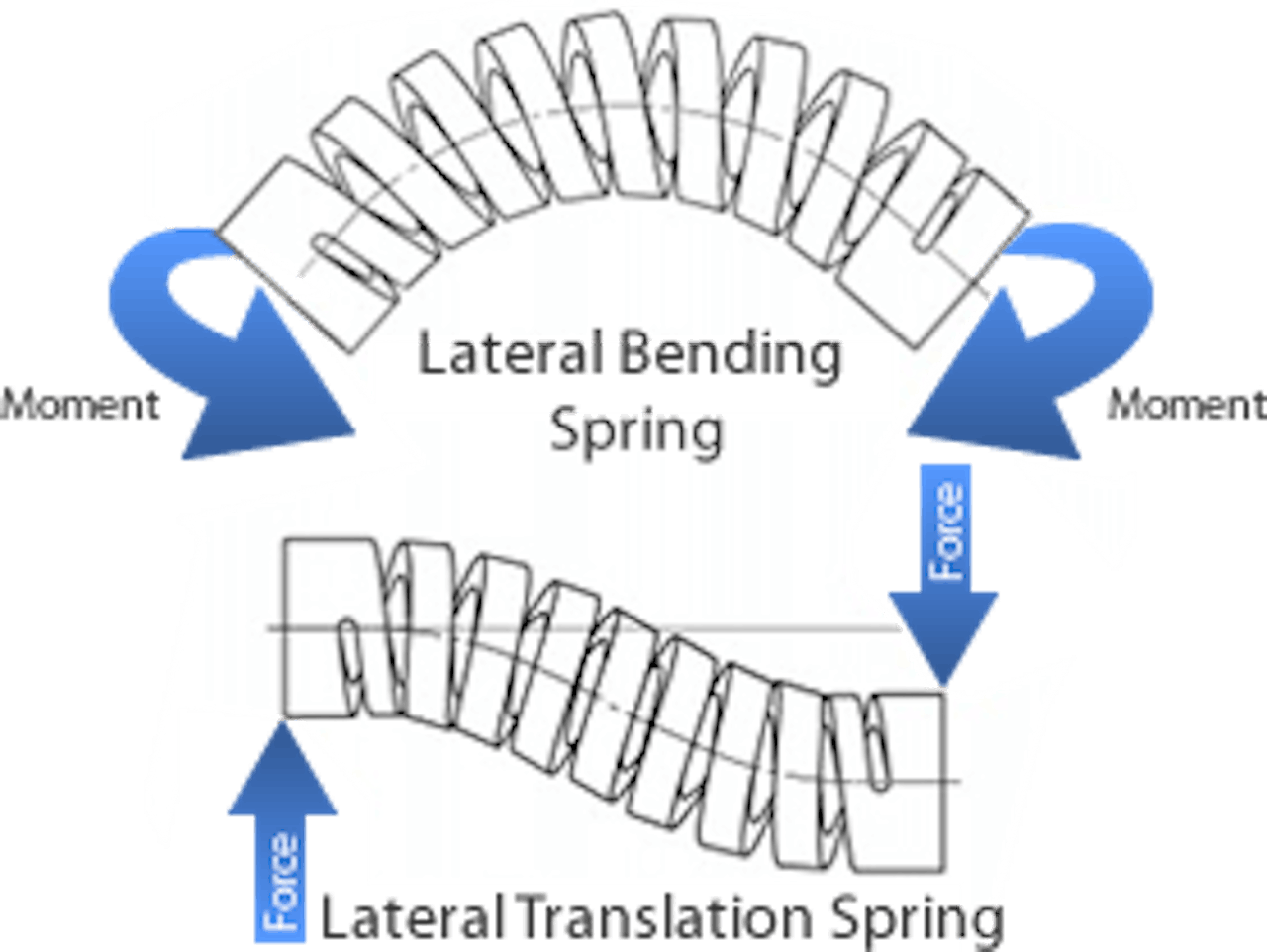

Lateral Bending & Translation

Additional benefits of the Helical spring can be realized in applications beyond the normal compression/extension or torsion load cases. The engineering staff at Helical Products can apply their expertise in engineered elasticity to spring designs involving lateral bending and/or lateral translation applications. Lateral bending is the result of anchoring at one end and applying a moment to the opposite end. Lateral translation occurs when one end of the spring is anchored and the other end has a force and moment applied to the opposite end. This causes the ends to remain parallel during displacement.

Leveraging the Helical machined spring's ability to provide both pre-determined elastic performance and integrate attachment features, all in a single piece enables significant design possibilities with the same reliable and repeatable performance that Helical Products is known for. The integrated attachments facilitate the anchoring of the spring and subsequent application of forces and/or moments with unprecedented ease. Changing the outside or inside diameters, as well as the number of starts, number of coils, and coil width, make it possible to provide desired spring rates in different axes of displacement.