About Springmasters

Springmasters is a leading manufacturer of machined parts, coiled springs, assemblies, and wire forms. We offer complete design, engineering, and manufacturing support for our customers requiring high precision products.

Springmasters delivers custom products with precision and versatility, and are experts at rapid prototyping. Because of the exacting standards within our industry, our manufacturing capabilities ensure quality in every product we make. State-of-the-art equipment allows us to manufacture products from a variety of materials and sizes. Quantities can range from one piece prototypes to large production runs.

Compliance

| Name | Original Approval | Certificate Expiry |

|---|---|---|

| ISO 9001 | 05/11/2022 | 05/10/2025 |

Industries we serve

A leading manufacturer for the transit and freight rail industries, Springmasters also serves customers in many other markets, including security, power generation, packaging, military, sporting goods, and consumer products.

Our Manufacturing Services

-

MW Components offers prototypes or sample parts for a variety of custom components including springs, fasteners, bellows, couplings, and other precision metal parts. We also offer rapid prototyping for select components, with shipping in as little as one week.

-

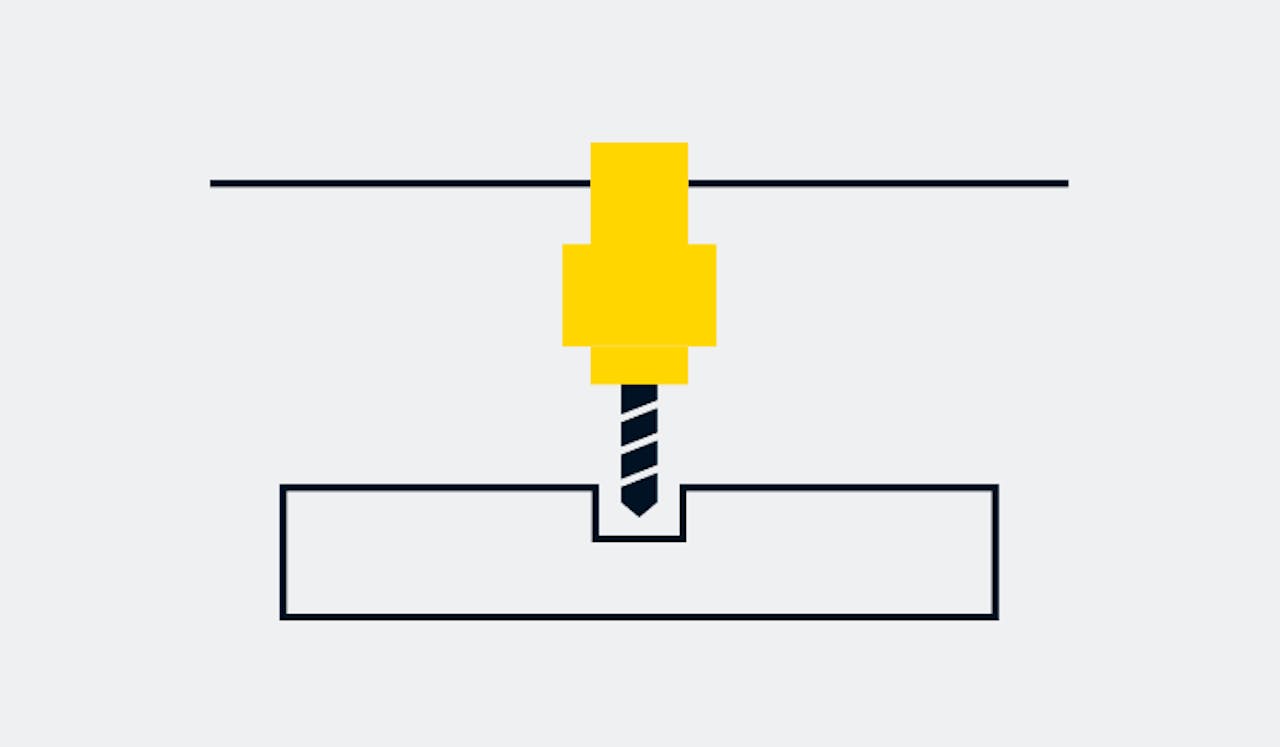

Milling

MillingMilling is accomplished using computerized controls to operate motorized cutting tools.

-

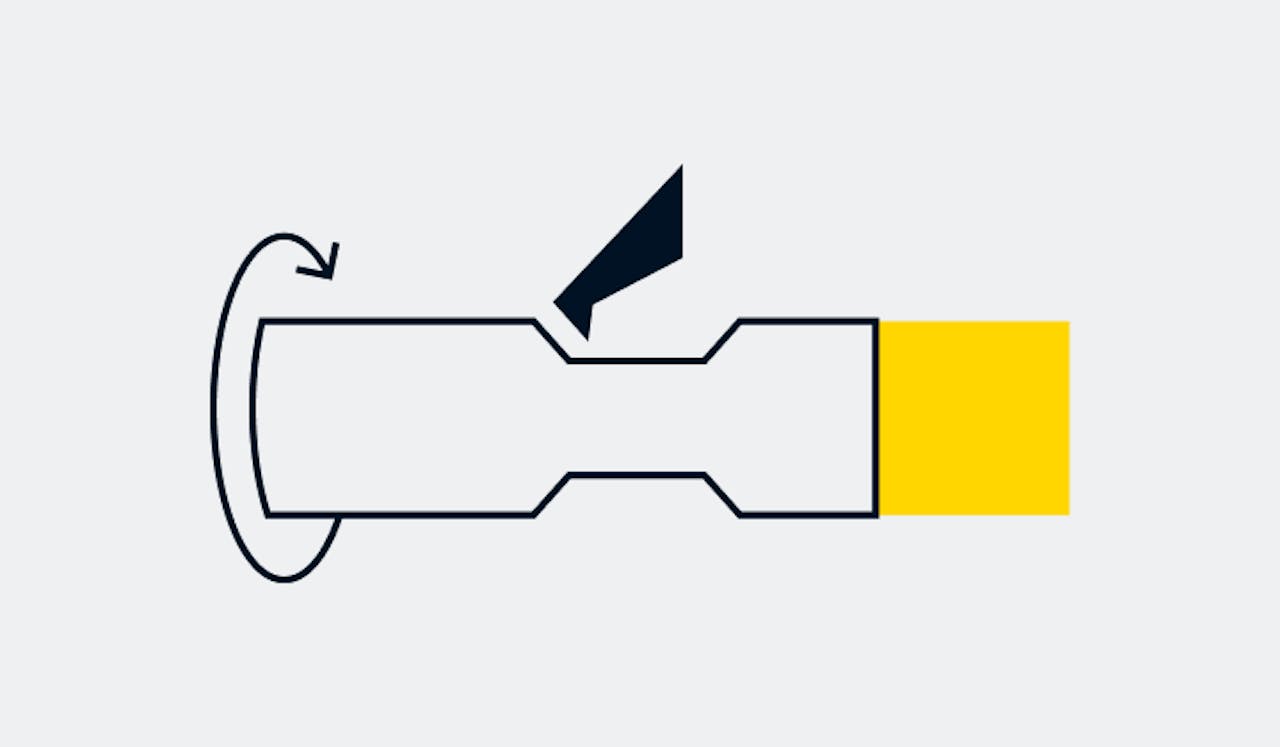

Turning

TurningThe manufacturing process known as CNC turning involves feeding metal bars into a machine and applying one or several tools that gradually shape the material into the desired form. Examples of capabilities that our precision turning centers have include Swiss lathe machining, threading, tapping, cross drilling, end or side milling, and broaching.

-

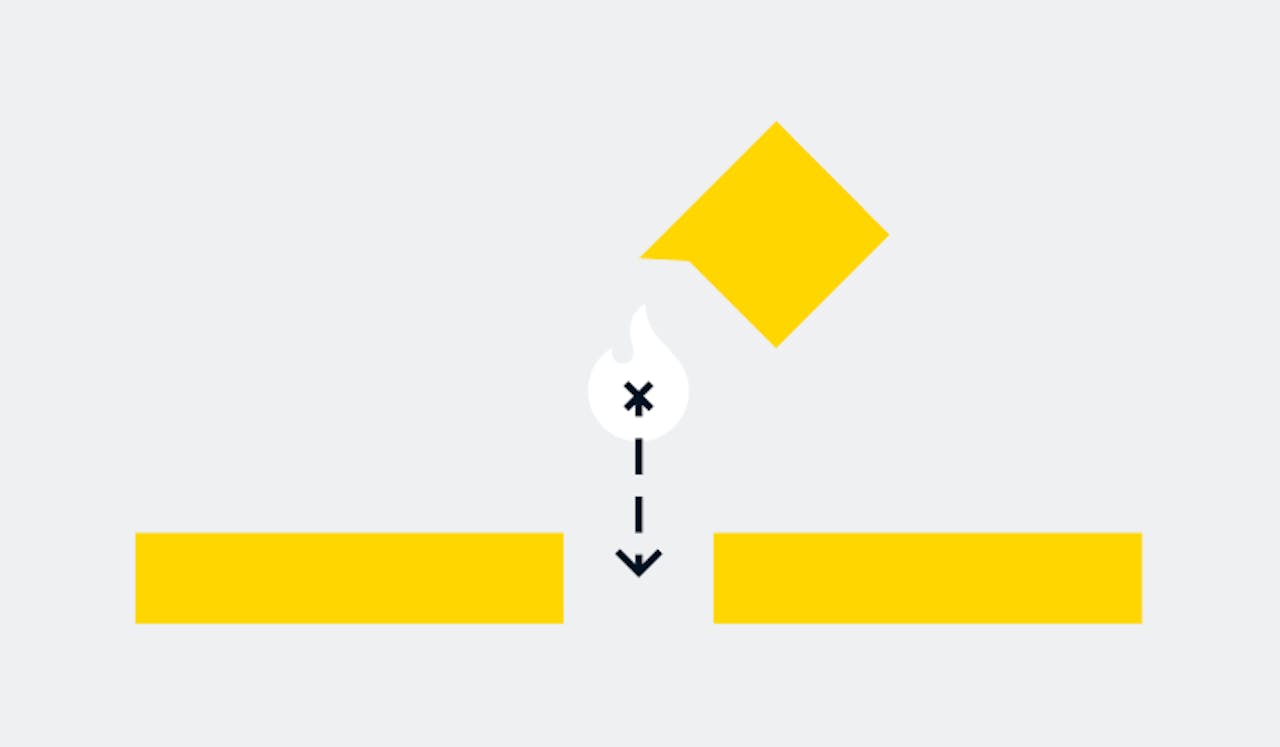

Brazing & Torchless Brazing

Brazing & Torchless BrazingBrazing is used to join metals by pouring a molten filler metal into the cavity between the joints. Some of our locations perform torchless induction brazing which can be used to join sub-assemblies. The assemblies can then be soft soldered to additional components.

-

Soldering

SolderingSoldering joins two or more materials together by filling the joint between the two with a melted filler metal. Unlike traditional welding methods, soldering does not require melting the original materials.

-

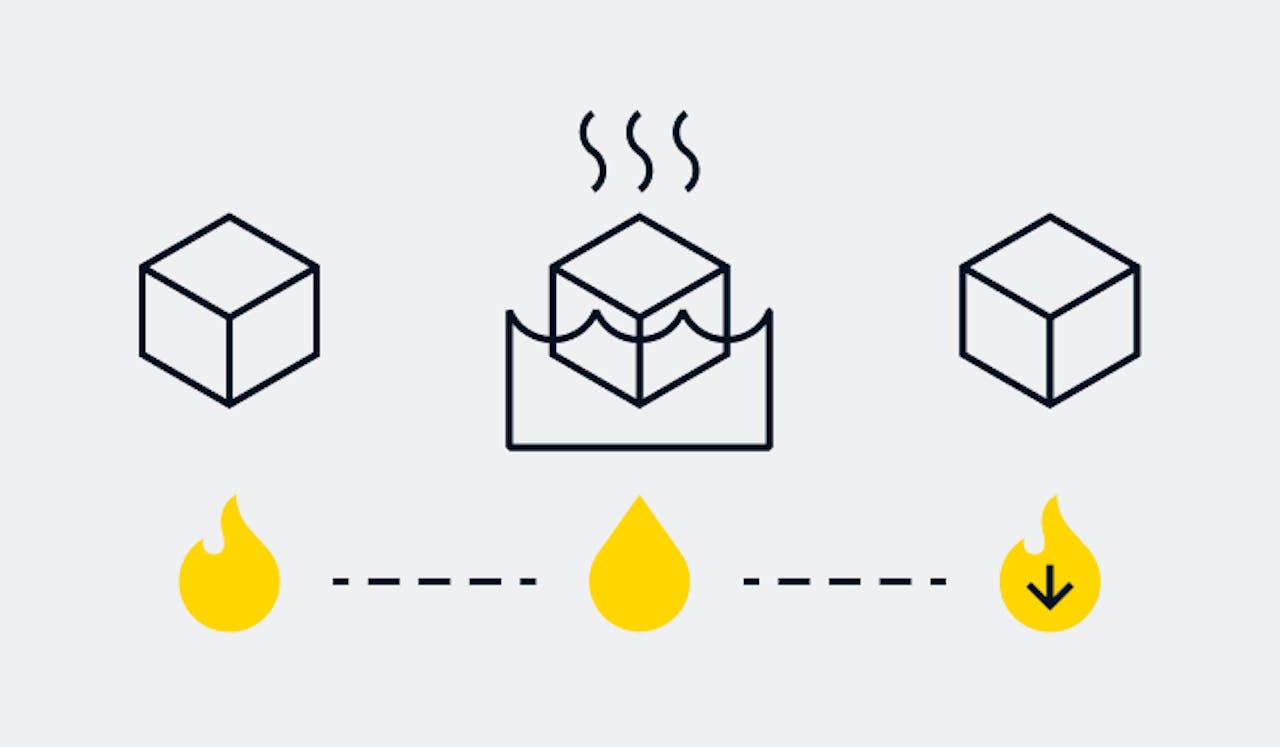

Hardening & Tempering

Hardening & TemperingHardening and tempering produce required hardness ratios in metals like steel or stainless steel to ensure desired performance. Harding, as well as case hardening, and straight hardening, involves heating the metal and then cooling it to transform its standard properties, while tempering is a process of applying low-temperature heat treatments, generally after a hardening process has been completed.

-

Would you like to make your overall production process more efficient? We offer part assembly services with both new and existing components. Ship your coordinating parts to us, and we’ll put them together to the requirements and timeline you specify.

-

Mag Particle / Magnafluxing

Mag Particle / MagnafluxingThis is an NDT process where a magnetic field is added directly or indirectly to the component and used to test certain metals like nickel, cobalt, iron, and their alloys for shallow surface inconsistencies.

-

Optimize your designs to reduce cost, improve performance, and accelerate time to market.